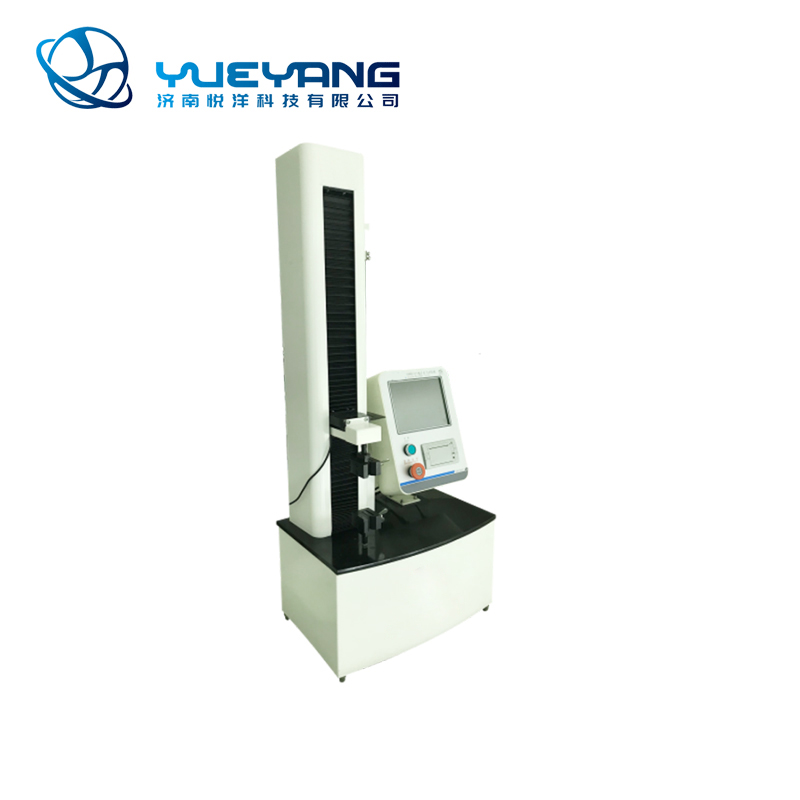

2022 High quality Testing Color Fastness Of Various Textiles - YY032G Fabric Bursting Strength (hydraulic method) – Yueyang

2022 High quality Testing Color Fastness Of Various Textiles - YY032G Fabric Bursting Strength (hydraulic method) – Yueyang Detail:

It is suitable for the test of breaking strength (pressure) and expansion degree of knitted fabrics, non-woven fabrics, leather, geosynthetic materials, etc.

GB/T7742.1-2005、FZ/T60019、FZ/T01030、ISO 13938.1、ASTM D 3786、JIS L1018.6.17.

1.The use of large screen touch color screen control, Chinese (English) menu operation (two languages optional), microcomputer program automatic control burst.

2.The sample clamping surface is a special tooth clamping surface, clamping force can be adjusted; Pneumatic clamping, sample clamping force and bursting force on the same axis; Can the whole party

It is suitable for clamping all kinds of materials.

3.The test area can be replaced to meet the requirements of different standards.

4. Equipped with servo driver and motor, hydraulic oil volume rate: 8ml/min ~ 500ml/min±10% (adjustable) feedback adjustment accurate control

To ensure that the sample is broken within 20±5S time. It truly reflects the bursting performance of the sample.

5.The test results are rich in expression, such as: breaking strength, breaking strength, diaphragm pressure, breaking height, breaking time; Convenient for quality control personnel

Fully understand the bursting performance of samples.

6. Increase the constant pressure, constant high auxiliary test method.

7. With printer interface, online interface.

8. With laser ranging system, breaking height measurement accuracy, no interference.

1. Test method: diaphragm burst method;

2. The sample clamp and clamping mode: the sample clamping surface is special tooth clamping surface, automatic pneumatic clamping, the sample clamping force and bursting force on the same axis;

3. Hydraulic oil volume rate range and accuracy: 8mL /min ~ 500ml/min (adjustable);

4.Test area: 50cm2 (φ 79.8mm±0.2mm), 7.3cm2 (φ 30.5mm±0.2mm) two areas can be replaced;

5.Bursting strength measurement range and resolution: 0 ~ 2000KPa, resolution: 1KPa;

6. Breaking strength control precision: ≤±1%;

7. Expansion measurement range: 0.1 ~ 70mm, accuracy ±0.1mm;

8. Control operation: large screen touch screen control, Chinese and English menu operation;

9. Test results: bursting strength, bursting strength, diaphragm pressure, bursting height, bursting time;

10. Test method: constant speed method, constant pressure method, constant height method three test methods;

11. Power supply: Ac220V,50Hz,1700W;

12. Overall size: 630×440×675mm (L×W×H) weighing about 150Kg.

1.Host—1 Set

2.Sample Plate–2 Sets

3.Stainless steel diaphragm compression ring—1 Pcs

4.Glycerin–2 Bottles

5.Diaphragm–1 Package(10pcs)

6.Online software CD-ROM—1 Pcs

1.Mute pump—1 Set

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for 2022 High quality Testing Color Fastness Of Various Textiles - YY032G Fabric Bursting Strength (hydraulic method) – Yueyang , The product will supply to all over the world, such as: Burundi, Oslo, Greece, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!