2022 High quality Testing Color Fastness Of Various Textiles - YY641 Smelting Point Instrument – Yueyang

2022 High quality Testing Color Fastness Of Various Textiles - YY641 Smelting Point Instrument – Yueyang Detail:

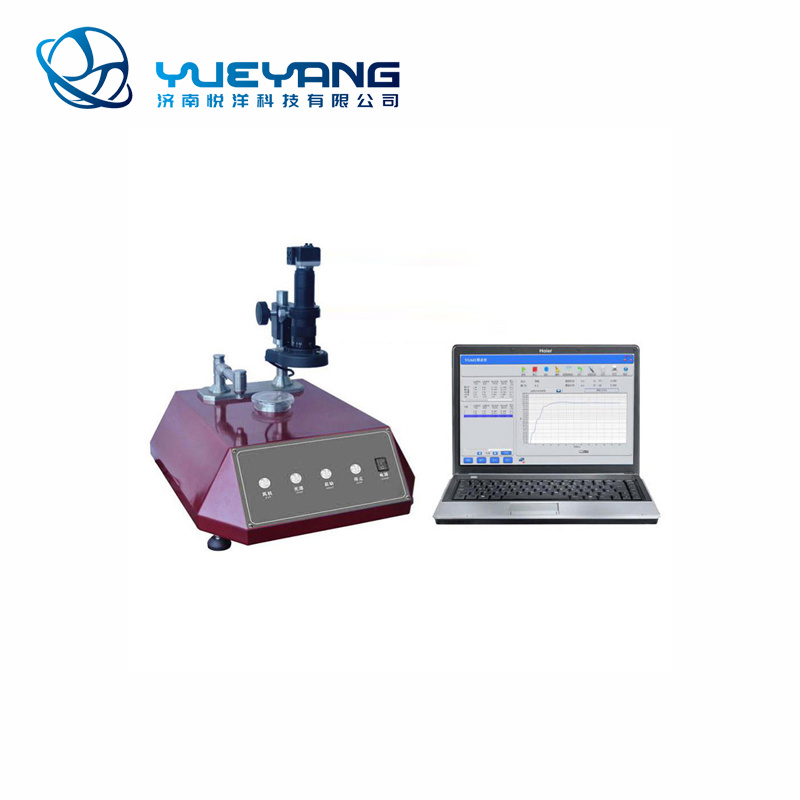

Used in textile, chemical fiber, building materials, medicine, chemical industry and other industries of organic matter analysis, can clearly observe the microscopic and articles under the heating state of the shape, color change and three state transformation and other physical changes.

1. The use of high-definition CCD camera and liquid crystal display, can clearly observe the melting process of objects;

2. PID algorithm is used to control heating to ensure the stability of temperature rise rate;

3. Automatic measurement, man-machine integration, no need to guard during the test, thus liberating productivity, improve work efficiency;

4. User-friendly interface, measurement data can be retrospectively traced (temperature rise, melting point value, light curve, test image can be stored), to achieve reduction

5. Purpose of market disputes;

5. Optimized structure design, accurate positioning;

6. There are two kinds of testing methods: microscopy and photometry, and the photometry can automatically calculate the results.

7. A wide range of application (medicine, chemical, building materials, textile, chemical fiber and other applications).

1. Melting point measurement range: room temperature ~ 320°C

2. Minimum reading value: 0.1°C

3.Measurement repeatability: ±1°C (at <200°C), ±2°C (at 200°C-300°C)

4. Linear heating rate: 0.5, 1,2,3,5 (°C/min)

5.The microscope magnification: ≤100 times

6.The use of the environment: temperature 0 ~ 40 ° C relative temperature 45 ~ 85%RH

7.Instrument weight: 10kg

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for 2022 High quality Testing Color Fastness Of Various Textiles - YY641 Smelting Point Instrument – Yueyang , The product will supply to all over the world, such as: Sevilla, St. Petersburg, Pretoria, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.