2022 Latest Design Flake Sample Drying - YYP116 Beating Pulp Tester – Yueyang

2022 Latest Design Flake Sample Drying - YYP116 Beating Pulp Tester – Yueyang Detail:

DRK116 Beating Pulp Tester is applied to test the filter ability of suspending pulp liquid. That is to say the determination of the beating degree.

According the inverse proportion relation between beating degree and draining velocity of suspending pulp liquid, designed as Schopper-Riegler beating degree tester.DRK116 Beating Pulp Tester is applied to test filterability of suspending pulp liquid and research fiber condition and evaluate beating degree.

Applying in testing filter ability of suspending pulp liquid, that is to say the determination of the beating degree.

ISO 5267.1 <Pulps – Determination of drain ability — Part 1: Schopper-Riegler method>

GB/T 3332 <Pulps – Determination of beating degree (Schopper-Riegler method)>

QB/T 1054 <Pulps – Tester of beating degree>

| Items | Parameters |

| Test Range | (1 ~ 100)SR |

| Cylinder Division Value | 1SR |

| Over fall part Sluicing Time | (149±1)s |

| Surplus Volume | (7.5 ~ 8)ml |

Mainframe; operating manual; Certificate of quality

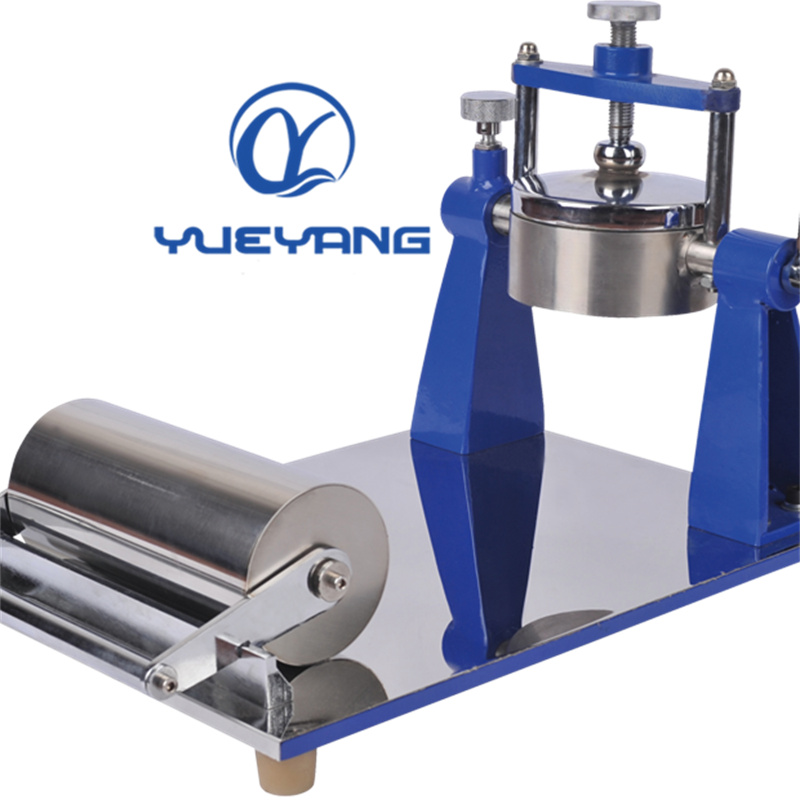

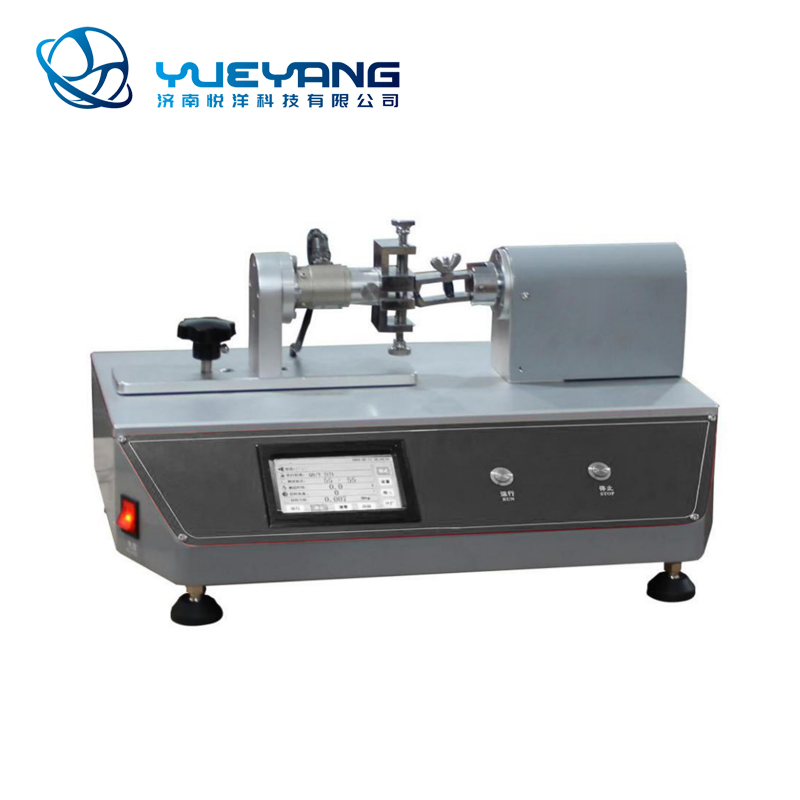

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for 2022 Latest Design Flake Sample Drying - YYP116 Beating Pulp Tester – Yueyang , The product will supply to all over the world, such as: Irish, Macedonia, Guatemala, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.