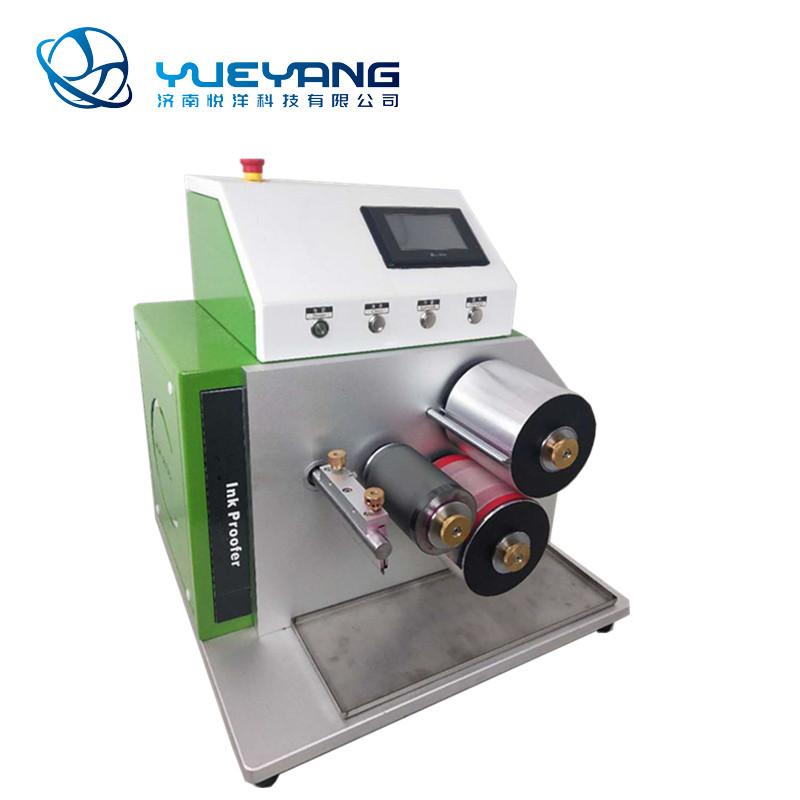

2022 Latest Design Zipper Pull Light Slip Tester - YYP200 Flexo Ink Proofer – Yueyang

2022 Latest Design Zipper Pull Light Slip Tester - YYP200 Flexo Ink Proofer – Yueyang Detail:

1.Control voltage: 24VDC Power: 0.5KW

2.Inking mode: pipette Ink Dropping

3.Proofing material thickness: 0.01-2mm (flexural material)

4.Proofing material size: 100x405mm

5.Printing area:90*240mm

6.Plate area: 120x405mm

7.Thickness: 1.7mm thickness: 0.3mm

8.Plate roller and net roller pressure:

Through motor regulation,

The pressure of the roller and the net roller is regulated by the motor and has the scale display pressure. The pressure of the roller and the net roller is regulated by the motor and has the scale display pressure.

9.Printing speed is adjustable: 10-130 m/min

10.Specification of ceramic mesh roll: Phi 80x120mm

11.The number of ceramic mesh rollers: Standard 500 lines (70-1200 lines can be customized)

12.Applicable ink:

Flexible water, UV ink, lithography, relief ordinary or UV ink

13.Applicable proofing materials:

Suitable proofing materials: paper, plastic film, non-woven fabric, napkins, gold and silver cardboard

paper, plastic film, non-woven fabrics, napkins, gold and silver cardboard, etc.

14.Appearance size: 550x515x420mm

15.Net weight of instrument: 88KG

① The instrument can be coated, solid color, dot pattern proofing.

② Ceramic roller rotates the ink evenly first, then the printing material is printed. The printing plate cylinder starts to rotate synchronously for one week to complete the proofing work. The ceramic roller, the printing material cylinder and the printing plate cylinder run synchronously to ensure the proofing quality.

③ Using private clothes and stepping motors, touch screen control, so that operation is more simple, more precise control.

④ Scraper, ceramic roller, printing plate roller, printing drum four structure can adjust the pressure, flexible adjustment;

⑤ Net roller, scraper cartridge disassembly and cleaning is simple and convenient.

⑥ The installation of printing materials, installation of printing plate and cleaning plate is simple and convenient.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for 2022 Latest Design Zipper Pull Light Slip Tester - YYP200 Flexo Ink Proofer – Yueyang , The product will supply to all over the world, such as: Pakistan, Myanmar, Kuwait, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.