Environmental test chamber

-

YYP-100 Temperature & Humidity Chamber(100L)

1)Equipment use:

The product is tested at high temperature and high humidity, low temperature and low humidity, which is suitable for the quality control testing of electronics, electrical appliances, batteries, plastics, food, paper products, vehicles, metals, chemicals, building materials, research institutes, inspection and quarantine Bureau, universities and other industry units.

2)Meeting the standard:

1. The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 “Basic parameter Verification Method of environmental test Equipment for electrical and electronic products Low temperature, high temperature, constant humid heat, alternating humid heat test equipment”

2. Basic environmental test procedures for electrical and electronic products Test A: Low temperature test method GB 2423.1-89 (IEC68-2-1)

3. Basic environmental test procedures for electrical and electronic products Test B: high temperature test method GB 2423.2-89 (IEC68-2-2)

4. Basic environmental test procedures for electrical and electronic products Test Ca: Constant wet heat test method GB/T 2423.3-93 (IEC68-2-3)

5. Basic environmental test procedures for electrical and electronic products Test Da: Alternating humidity and heat test method GB/T423.4-93(IEC68-2-30)

-

800 Xenon lamp weathering test chamber(electrostatic spray)

Summary:

The destruction of materials by sunlight and moisture in nature causes incalculable economic losses every year. The damage caused mainly includes fading, yellowing, discoloration, strength reduction, embrittlement, oxidation, brightness reduction, cracking, blurring and chalking. Products and materials that are exposed to direct or behind-the-glass sunlight are at greatest risk of photodamage. Materials exposed to fluorescent, halogen, or other light-emitting lamps for extended periods of time are also affected by photodegradation.

The Xenon Lamp Weather Resistance Test Chamber uses a xenon arc lamp that can simulate the full sunlight spectrum to reproduce the destructive light waves that exist in different environments. This equipment can provide corresponding environmental simulation and accelerated tests for scientific research, product development and quality control.

The 800 xenon lamp weather resistance test chamber can be used for tests such as selection of new materials, improvement of existing materials or evaluation of changes in durability after changes in material composition. The device can well simulate the changes in materials exposed to sunlight under different environmental conditions.

-

315 UV Aging Test Chamber(Electrostatic spraying cold rolled steel)

Equipment use:

This test facility simulates the damage caused by sunlight, rain, and dew by exposing the material under test to an alternating cycle of light and water at controlled high temperatures. It uses ultraviolet lamps to simulate the radiation of sunlight, and condensates and water jets to simulate dew and rain. In just a few days or a few weeks, UV irradiation equipment can be re-outdoor takes months or even years to occur damage, including fading, color change, tarnish, powder, cracking, cracking, wrinkling, foaming, embrittlement, strength reduction, oxidation, etc., the test results can be used to select new materials, improve existing materials, and improve the quality of the material. Or evaluate changes in material formulation.

Meeting the standards:

1.GB/T14552-93 “National Standard of the People’s Republic of China – Plastics, coatings, rubber materials for machinery industry products – artificial climate accelerated test method” a, fluorescent ultraviolet/condensation test method

2. GB/T16422.3-1997 GB/T16585-96 correlation analysis method

3. GB/T16585-1996 “People’s Republic of China national standard a vulcanized rubber artificial climate aging (fluorescent ultraviolet lamp) test method”

4.GB/T16422.3-1997 “Plastic laboratory light exposure test method” and other corresponding standard provisions design and manufacturing Standard in line with international testing standards :ASTM D4329, IS0 4892-3, IS0 11507, SAEJ2020 and other current UV aging test standards.

-

YY4660 Ozone Aging Chamber(Stainless steel model)

Main technical requirements:

1. Studio scale (mm) : 500×500×600

2. Ozone concentration: 50-1000PPhm(direct reading, direct control)

3. Ozone concentration deviation: ≤10%

4. Test chamber temperature: 40℃

5. Temperature uniformity: ±2℃

6. Temperature fluctuation: ≤±0.5℃

7. Test chamber humidity: 30~98%R·H

8. Test return speed: (20-25) mm/s

9. Gas flow rate of test chamber: 5-8mm/s

10. Temperature range: RT~60℃

-

YY4660 Ozone Aging Chamber(Baking paint type)

Main technical requirements:

1. Studio scale (mm) : 500×500×600

2. Ozone concentration: 50-1000PPhm(direct reading, direct control)

3. Ozone concentration deviation: ≤10%

4. Test chamber temperature: 40℃

5. Temperature uniformity: ±2℃

6. Temperature fluctuation: ≤±0.5℃

7. Test chamber humidity: 30~98%R·H

8. Test return speed: (20-25) mm/s

9. Gas flow rate of test chamber: 5-8mm/s

10. Temperature range: RT~60℃

-

YYP-150 High Precision Constant Temperature &Humidity Test Chamber

1)Equipment use:

The product is tested at high temperature and high humidity, low temperature and low humidity, which is suitable for the quality control testing of electronics, electrical appliances, batteries, plastics, food, paper products, vehicles, metals, chemicals, building materials, research institutes, inspection and quarantine Bureau, universities and other industry units.

2)Meeting the standard:

1. The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 “Basic parameter Verification Method of environmental test Equipment for electrical and electronic products Low temperature, high temperature, constant humid heat, alternating humid heat test equipment”

2. Basic environmental test procedures for electrical and electronic products Test A: Low temperature test method GB 2423.1-89 (IEC68-2-1)

3. Basic environmental test procedures for electrical and electronic products Test B: high temperature test method GB 2423.2-89 (IEC68-2-2)

4. Basic environmental test procedures for electrical and electronic products Test Ca: Constant wet heat test method GB/T 2423.3-93 (IEC68-2-3)

5. Basic environmental test procedures for electrical and electronic products Test Da: Alternating humidity and heat test method GB/T423.4-93(IEC68-2-30)

-

YYP-225 High&low Temperature Test Chamber(Stainless steel)

I .Performance specifications:

Model YYP-225

Temperature range: -20 ℃ To + 150 ℃

Humidity range:20 % to 98﹪ RH (Humidity is available from 25° to 85°)Except for custom

Power: 220 V

II. System structure:

1. Refrigeration system: multi-stage automatic load capacity adjustment technology.

a. Compressor: imported from France Taikang full hermetic high efficiency compressor

b. Refrigerant: environmental refrigerant R-404

c. Condenser: air-cooled condenser

d. Evaporator: fin type automatic load capacity adjustment

e. Accessories: desiccant, refrigerant flow window, repair cutting, high voltage protection switch.

f. Expansion system: freezing system for capillary capacity control.

2. Electronic system (safety protection system):

a. Zero crossing thyristor power controller 2 groups (temperature and humidity each group)

b. Two sets of air burn prevention switches

c. Water shortage protection switch 1 group

d. Compressor high pressure protection switch

e. Compressor overheat protection switch

f. Compressor overcurrent protection switch

g. Two fast fuses

h. No fuse switch protection

i. Line fuse and fully sheathed terminals

3. Duct system

a. Made of Taiwan 60W lengthened stainless steel coil.

b. Multi-wing Chalcosaurus speed up the amount of heat and humidity circulation.

4. Heating system: flake type stainless steel electric heat pipe.

5. Humidification system: stainless steel humidifier pipe.

6. Temperature sensing system: stainless steel 304PT100 two dry and wet sphere comparison input through A/D conversion temperature measurement humidity.

7. Water System:

a. Built-in stainless steel water tank 10L

b. Automatic water supply device (pumping water from the lower level to the upper level)

c. Water shortage indication alarm.

8. Control system: Control system adopts P.I.D controller, temperature and humidity control at the same time (see independent version)

a. Controller specifications:

*Control accuracy: temperature ±0.01℃+1digit, humidity ±0.1%RH+1digit

*has upper and lower limit standby and alarm function

*Temperature and humidity input signal PT100×2(dry and wet bulb)

*Temperature and humidity conversion output :4-20MA

*6 groups of P.I.D control parameter Settings P.I.D automatic calculation

*Automatic wet and dry bulb calibration

b. Control function:

*has the function of booking start and shutdown

*with date, time adjustment function

9. Chamber material

Inner box material: stainless steel

Outer box material: stainless steel

Insulation material

V rigid foam + glass wool

V rigid foam + glass wool -

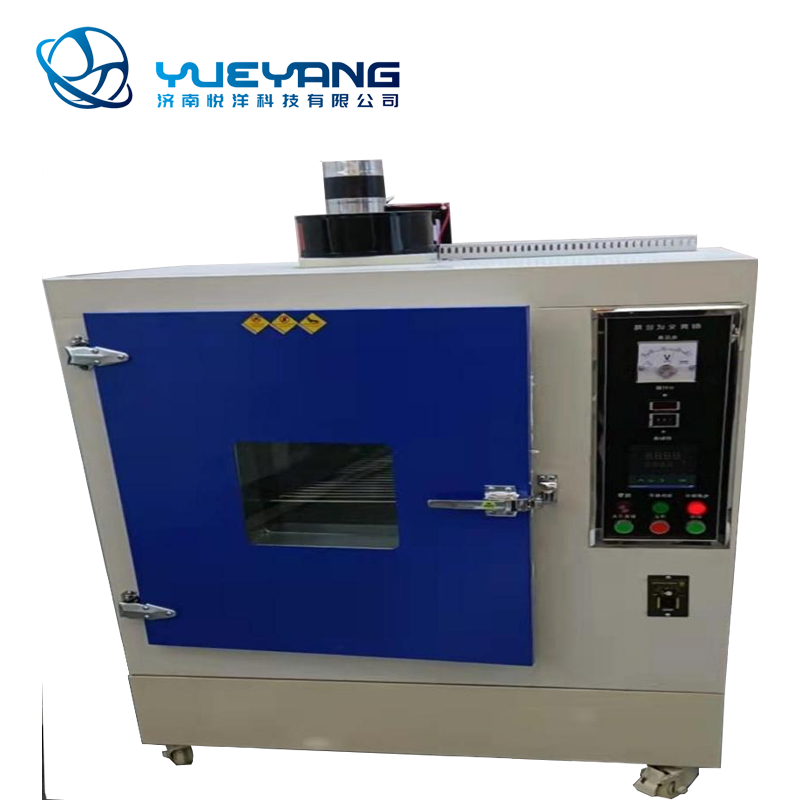

YYP-125L High Temperature Test Chamber

Specification:

1. Air supply mode: forced air supply cycle

2. Temperature range: RT ~ 200℃

3. Temperature fluctuation: 3℃

4. Temperature uniformity: 5℃%(no load).

5. Temperature measuring body: PT100 type thermal resistance (dry ball)

6. Inner box material: 1.0mm thickness stainless steel plate

7. Insulation material: highly efficient ultra-fine insulation rock wool

8. Control mode: AC contactor output

9. Pressing: high temperature rubber strip

10. Accessories: Power cord 1 m,

11. Heater material: shockproof dynamic anti-collision fin heater (nickel-chromium alloy)

13. Power :6.5KW

-

150 UV Aging Test Chamber

Summarize:

This chamber uses the fluorescent ultraviolet lamp that best simulates the UV spectrum of sunlight, and combines temperature control and humidity supply devices to simulate the high temperature, high humidity, condensation, dark rain cycle and other factors that cause discoloration, brightness, intensity decline, cracking, peeling, pulverization, oxidation and other damage to the material in the sunlight (UV segment). At the same time, through the synergistic effect between ultraviolet light and moisture, the single light resistance or single moisture resistance of the material is weakened or failed, which is widely used in the evaluation of the material’s weather resistance. The equipment has the best sunlight UV simulation, low maintenance cost, easy to use, automatic operation of the equipment with control, high degree of automation of the test cycle, and good lighting stability. High reproducibility of test results. The whole machine can be tested or sampled.

Scope of application:

(1)QUV is the most widely used weather test machine in the world

(2) It has become the world standard for accelerated laboratory weathering test: in line with ISO, ASTM, DIN, JIS, SAE, BS, ANSI, GM, U.S.OVT and other standards.

(3) Fast and true reproduction of sun, rain, dew damage to materials: in only a few days or weeks, QUV can reproduce outdoor damage that takes months or years to produce: including fading, discoloration, brightness reduction, powder, cracking, blurring, embrittlement, strength reduction and oxidation.

(4)QUV reliable aging test data can make accurate correlation prediction of product weather resistance (anti-aging), and help to screen and optimize materials and formulations.

(5) Widely used industries, such as: coatings, inks, paints, resins, plastics, printing and packaging, adhesives, automobiles, motorcycle industry, cosmetics, metals, electronics, electroplating, medicine, etc.

Comply with international testing standards :ASTM D4329, D499, D4587, D5208, G154, G53; ISO 4892-3, ISO 11507; EN 534; EN 1062-4, BS 2782; JIS D0205; SAE J2020 D4587 and other current UV aging test standards.

-

225 UV Aging Test Chamber

Summary:

It is mainly used to simulate the damage effect of sunlight and temperature on materials; Aging of materials includes fading, loss of light, loss of strength, cracking, peeling, pulverization and oxidation. The UV aging test chamber simulates sunlight, and the sample is tested in a simulated environment for a period of days or weeks, which can reproduce the damage that may occur outdoors for months or years.

Widely used in coating, ink, plastic, leather, electronic appliances and other industries.

Technical Parameters

1. Inner box size: 600*500*750mm (W * D * H)

2. Outer box size: 980*650*1080mm (W * D * H)

3. Inner box material: high quality galvanized sheet.

4. Outer box material: heat and cold plate baking paint

5. Ultraviolet irradiation lamp: UVA-340

6.UV lamp only number: 6 flat on the top

7. Temperature range: RT+10℃~70℃ adjustable

8. Ultraviolet wavelength: UVA315~400nm

9. Temperature uniformity: ±2℃

10. Temperature fluctuation: ±2℃

11. Controller: digital display intelligent controller

12. Test time: 0~999H (adjustable)

13. Standard sample rack: one layer tray

14. Power supply :220V 3KW

-

1300 UV Aging Test Chamber (Leaning Tower type)

Summarize:

This product uses the fluorescent UV lamp that best simulates the UV spectrum of

sunlight, and combines the device of temperature control and humidity supply

Material caused by discoloration, brightness, strength decline, cracking, peeling,

powder, oxidation and other damage of the sun (UV segment) high temperature,

Dampness, condensation, dark rain cycle and other factors, at the same time

through the synergistic effect between ultraviolet light and moisture make the

material single resistance.The ability or single moisture resistance is weakened or

failed, which is widely used for evaluating the weather resistance of materials, and

the equipment has to Provide Good sunlight UV simulation, low maintenance cost,

easy to use, equipment using control automatic operation, test cycle from High

degree of chemistry, goodlighting stability, high reproducibility of test results.

(Suitable for small products or sample testing) tablets .The product is appropriate.

Scope of application:

(1)QUV is the most widely used weather test machine in the world

(2) It has become the world standard for accelerated laboratory weathering test: in line with ISO, ASTM, DIN, JIS, SAE, BS, ANSI, GM, U.S.OVT and other standards and national standards.

(3) Fast and true reproduction of high temperature, sunlight, rain, condensation damage to the material: in only a few days or weeks, QUV can reproduce outdoor damage that takes months or years to produce: including fading, discoloration, brightness reduction, powder, cracking, blurring, embrittlement, strength reduction and oxidation.

(4)QUV reliable aging test data can make accurate correlation prediction of product weather resistance (anti-aging), and help to screen and optimize materials and formulations.

(5) A wide range of applications, such as: coatings, inks, paints, resins, plastics, printing and packaging, adhesives, automobiles

Motorcycle industry, cosmetics, metal, electronics, electroplating, medicine, etc.

Comply with international testing standards :ASTM D4329, D499, D4587, D5208, G154, G53; ISO 4892-3, ISO 11507; EN 534; prEN 1062-4, BS 2782; JIS D0205; SAE J2020 D4587; GB/T23987-2009, ISO 11507:2007, GB/T14522-2008,ASTM-D4587 and other current UV aging test standards.

-

(China)YY4620 Ozone Aging Chamber(electrostatic spray)

Used in ozone environment conditions, the rubber surface accelerated aging, so that there is a potential frosting phenomenon of unstable substances in the rubber will accelerate free (migration) precipitation, there is a frosting phenomenon test.

-

(China)YYP 50L Constant Temperature&Humidity Chamber

Meeting standard:

The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 “Basic parameter Verification method of environmental test equipment for electrical and electronic products Low temperature, high temperature, constant wet heat, alternating wet heat test equipment”

Basic environmental test procedures for electrical and electronic products Test A: Low temperature

test method GB 2423.1-89 (IEC68-2-1)

Basic environmental test procedures for electrical and electronic products Test B: High temperature

test method GB 2423.2-89 (IEC68-2-2)

Basic environmental test procedures for electrical and electronic products Test Ca: Constant wet

heat test method GB/T 2423.3-93 (IEC68-2-3)

Basic environmental test procedures for electrical and electronic products Test Da: Alternating

humidity and heat test method GB/T423.4-93(IEC68-2-30)

-

(China)YY NH225 Yellowing Resistance Aging Oven

Summary:

It is manufactured in accordance with ASTM D1148 GB/T2454HG/T 3689-2001, and its function

is to simulate the ultraviolet radiation and heat of sunlight. The sample is exposed to ultraviolet

radiation and temperature in the machine, and after a period of time, the degree of yellowing

resistance of the sample is observed. The staining gray label can be used as a reference to

determine the grade of yellowing. The product is affected by sunlight radiation during use or the

influence of the container environment during transportation, resulting in the color change of the

product.

-

(China)YYS Series Biochemical Incubator

Structure

The biochemical incubator of this series consists of a cabinet, a temperature control device,

a heating refrigeration system, and a circulating air duct. The box chamber is made of mirror

stainless steel, surrounded by circular arc structure, easy to clean. The case shell is sprayed

with high quality steel surface. The box door is equipped with an observation window, which is convenient for observing the state of the test products in the box. The height of the screen can

be adjusted arbitrarily.

The heat insulation property of the polyurethane foam board between the workshop and the box

is good, and the insulation performance is good. The temperature control device mainly consists

of a temperature controller and a temperature sensor. The temperature controller has the functions

of over-temperature protection, timing and power-off protection. The heating and refrigeration system

is composed of heating tube, evaporator, condenser and compressor. Gas circulating air duct, this series of biochemical box circulating air duct design is reasonable, to maximize the temperature uniformity in the box. The biochemical box is equipped with a lighting device to facilitate users to observe objects in the box.

-

(China)YY-800C/ CH Constant Temperature&Humidity Chamber

Major dispositions:

1.Temperature range: A: -20°C to 150 °C B: -40 °C to 150 °C C: -70-150°C

2.Humidity range: 10% relative humidity to 98% relative humidity

3.Display instrument: 7-inch TFT color LCD display (RMCS control software)

4.Operation mode: fixed value mode, program mode (preset 100 sets 100 steps 999 cycles)

5.Control mode: BTC balance temperature control mode + DCC (intelligent cooling

control) + DEC (intelligent electrical control) (temperature test equipment)

BTHC balance temperature and humidity control control mode + DCC (intelligent cooling control) + DEC (intelligent electrical control) (temperature and humidity test equipment)

6.Curve recording function: RAM with battery protection can save the equipment

Set value, sampling value and sampling time; the maximum recording time is 350

days (when the sampling period is 1 / min).

7.Software usage environment: the upper computer operating software is

compatible with XP, Win7, Win8, Win10 operating system (user-provided)

8.Communication function: RS-485 interface MODBUS RTU communication

protocol,

9.Ethernet interface TCP / IP communication protocol two option; support

secondary development Provide upper computer operation software, RS-485 interface single device link, Ethernet interface can realize remote communication of multiple devices.

10.Working mode: A / B: mechanical single stage compression refrigeration system C: double stage stack compressor refrigeration mode

11.Observation mode: heated observation window with LED internal lighting

12.Temperature and humidity sensing mode: temperature: Class A PT 100 armoured thermocouple

13.Humidity: Class A type PT 100 armoured thermocouple

14.Dry and wet bulb thermometer (only during humidity controlled tests)

15.Safety protection: fault alarm and cause, processing prompt function, power off protection function, upper and lower limit temperature protection function, calendar timing function (automatic start and automatic stop operation), self-diagnosis function

16.Verification configuration: Access hole with silicone plug (50 mm, 80mm, 100mm left)

Data interface: Ethernet + software, USB data export, 0-40MA signal output

-

(China)YYP643 Salt Spray Corrosion Test Chamber

YYP643 Salt spray corrosion test chamber with latest PID control is widely

used in

salt spray corrosion test of electroplated parts, paints, coatings, automobile

and motorcycle parts, aviation and military parts, protective layers of metal

materials,

and industrial products such as electric and electronic systems.

-

(China)YY-90 Salt Spray Tester -Touch-screen

I.Use:

Salt spray tester machine is mainly used for surface treatment of various materials, including paint. Electroplating. Inorganic and coated, anodized. After anti-rust oil and other anti-corrosion treatment, the corrosion resistance of its products is tested.

II.Features:

1. Imported digital display controller full digital circuit design, accurate temperature control, long service life, complete testing functions;

2. When working, the display interface is dynamic display, and there is a buzzer alarm to remind the working status; The instrument adopts ergonomic technology, easy to operate, more user-friendly;

3. With automatic/manual water adding system, when the water level is insufficient, it can automatically replenish the water level function, and the test is not interrupted;

4. Temperature controller using touch screen LCD display, PID control error ± 01.C;

5. Double overtemperature protection, insufficient water level warning to ensure safe use.

6. The laboratory adopts the direct steam heating method, the heating rate is fast and uniform, and the standby time is reduced.

7. The precision glass nozzle is evenly diffused by the conical disperser of the spray tower with adjustable fog and fog volume, and naturally falls on the test card, and ensures that there is no crystallization salt blockage.

-

(China)YYS-150 High & low Temperature Humid Heat Alternating Test Chamber

1.Stainless steel 316L finned heat dissipating heat pipe electric heater.

2.Control mode: PID control mode, using non-contact and other periodic pulse broadening SSR (solid state relay)

3.TEMI-580 True Color Touch programmable Temperature and Humidity controller

4.Program control 30 groups of 100 segments (the number of segments can be arbitrarily adjusted and allocated to each group)

-

(China)YYS-1200 Rain Test Chamber

Function overview:

1. Carry out rain test on the material

2. Equipment standard: Meet the standard GB/T4208, IPX0 ~ IPX6, GB2423.38, GJB150.8A test requirements.