Excellent quality Textiles-Burning Behaviour-Vertical Method - YY026MG Electronic Tensile Strength Tester – Yueyang

Excellent quality Textiles-Burning Behaviour-Vertical Method - YY026MG Electronic Tensile Strength Tester – Yueyang Detail:

This instrument is the domestic textile industry powerful test configuration of high-grade, perfect function, high precision, stable and reliable performance model. Widely used in yarn, fabric, printing and dyeing, fabric, clothing, zipper, leather, nonwoven, geotextile and other industries of breaking, tearing, breaking, peeling, seam, elasticity, creep test.

GB/T、FZ/T、ISO、ASTM

1. Adopt imported servo driver and motor (vector control), the motor response time is short, no speed overrush, speed uneven phenomenon.

2. Selected ball screw and precision guide rail produced by Germany Rexroth Company, with long service life, low noise and low vibration.

3. Equipped with imported encoder to accurately control the positioning and elongation of the instrument.

4. Equipped with high precision sensor, “STMicroelectronics” ST series 32-bit MCU, 24 A/D converter.

5. Equipped with pneumatic fixture, the clip can be replaced, and can be customized with customer materials.

6.Can be customized according to customer requirements.

7. Online software support Windows operating system,

8. The instrument supports the host and computer two-way control.

9.Pre tension software digital setting.

10. Distance length digital setting, automatic positioning.

11. Conventional protection: mechanical switch protection, upper and lower limit travel, overload protection, over-voltage, over-current, overheating, under-voltage, under-current, leakage automatic protection, emergency switch manual protection.

12. Tear, peel test curve peak selection and determination conditions can be set by the customer.

13. Force value calibration: digital code calibration (authorization code), convenient instrument verification, control precision.

14. The whole machine circuit standard modular design, convenient instrument maintenance and upgrade.

1. The software supports Windows operating system, out of the box, very convenient, without professional training.

2. The computer online software support Chinese and English operation.

3. Solidify the test program confirmed by the user, each parameter has a default value, the user can modify.

4. Parameter setting interface: sample material number, color, batch, sample number and other parameters are independently set and printed or saved to.

5. The function of zooming in and out of the selected points of the test curve. Click any point of the test point to display the tensile and elongation values.

6. The test data report can be converted into Excel, Word, etc., automatic monitoring test results, convenient to connect with customer enterprise management software.

7.The test curve is saved to the PC, so as to record the inquiry.

8. The test software includes a variety of material strength test methods, so that the test is more convenient, fast, accurate and low cost operation.

9. The selected part of the curve can be zoomed in and out at will during the test.

10. The tested sample curve can be displayed in the same report as the test result.

11. Statistical point function, namely reading the data on the measured curve, can provide a total of 20 groups of data, and obtain the corresponding elongation or force value according to the different force value or elongation input by users.

15. Multiple curve superposition function.

16. Test units can be arbitrarily converted, such as Newton, pounds, kilogram force and so on.

17. Software analysis function: breaking point, breaking point, stress point, yield point, initial modulus, elastic deformation, plastic deformation, etc.

18.Unique (host, computer) two-way control technology, so that the test is convenient and fast, the test results are rich and varied (data reports, curves, graphs, reports).

1. Range and indexing value: 2500N, 0.05N; 500 N, 0.005 N

2. Force resolution is 1/300000

3. Force sensor accuracy: ≤±0.05%F·S

4. The machine load accuracy: full range of 2% ~ 100% any point accuracy ≤±0.1%, grade: 1 level

5. The beam speed adjustment range (up, down, speed regulation, fixed speed) ![]() 0.1 ~ 1000) mm/min (within the range of free setting)

0.1 ~ 1000) mm/min (within the range of free setting)

6. Effective stroke: 800mm

7. Displacement resolution: 0.01mm

8.The minimum clamping distance: 10mm

9. Clamping distance positioning mode: digital setting, automatic positioning

10. Gantry width: 360mm

11. Unit conversion: N, CN, IB, IN

12. Data storage (host part) :≥2000 groups

13. Power supply: 220V,50HZ,1000W

14. External size: 800mm×600mm×2000mm (L×W×H)

15. Weight: 220kg

1. Host—1 Pcs

2.Clamps:

1)Pneumatic Clamps– 1 Set( Including clampsing sheet:25×25,60×40,160×40mm)

2)Comply with GB/T19976-2005 steel ball bursting strength function pneumatic clamping clamps—1 Set

3.High quality silent air pump–1 Set

4.On line analysis software—1 Set

5.On-line communication accessories—1 Set

6.Load Cell: 2500N/500N

7.Software configuration: quality control operating software (CD)—1 PCS

8.Tensile Clamps:

2N—1 Pcs

5N—1 Pcs

10N—1 Pcs

GB/T3923.1—Textiles – Determination of tensile strength at break and elongation at break – Strip method

GB/T3923.2—Textiles — Determination of tensile properties of fabrics — Determination of breaking strength and elongation at break — Grasping method

GB/T3917.2-2009—Tearing property of textiles – Determination of tearing strength of trousers specimen (single seam)

GB/T3917.3-2009—Textiles – Determination of tearing strength of trapezoidal specimens

GB/T3917.4-2009—-Textiles – Tearing properties of lingual specimens (double seam) – Determination of tearing strength

GB/T3917.5-2009—Textiles – Tearing properties of fabrics – Determination of tearing strength of airfoil specimens (single seam)

GB/T 32599-2016— Test method for shedding strength of textile accessories

FZ/T20019-2006—Test method for delamination of woolen woven fabrics

FZ/T70007—Test method for underarm seam strength of knitted jackets

GB/T13772.1-2008—Textile machines – Determination of the resistance of yarns to slip at joints – Part 1: method of constant slip

GB/T13772.2-2008—Textile machines – Determination of yarn resistance to slip at joints – Part 1: Fixed load method

GB/T13773.1-2008—Textiles – Joint tensile properties of fabrics and their products – Part 1: Determination of joint strength by strip methodGB/T13773.2-2008—Textiles – Joint tensile properties of fabrics and their products – Part 1: Determination of joint strength by the grab method

GB/T19976-2005–Textiles – Determination of bursting strength – Ball method

FZ/T70006-2004—Knitted fabric tensile elastic recovery test method of fixed load

FZ/T70006-2004—Test of elastic recovery rate of knitted fabrics by fixed elongation method

FZ/T70006-2004—Stress relaxation in tensile elastic recovery test of knitted fabric

FZ/T70006-2004—Knitted fabric tensile elastic recovery test method of fixed elongation

FZ/T80007.1-2006—Test method for peel strength of garments using adhesive lining

FZ/T 60011-2016- –Test method for peel strength of composite fabrics

FZ/T 01030-2016— Knitted and elastic woven fabrics — Determination of joint strength and expansion — Top-breaking method

FZ/T01030-1993—Textiles – Determination of bursting strength – Ball method

FZ/T 01031-2016— Knitted and elastic woven fabrics — Determination of joint strength and elongation — Grab sampling method

FZ/T 01034-2008— Textiles – Test method for tensile elasticity of woven fabrics

ISO 13934-1:2013—Textiles – Tensile properties of fabrics – Part 1: Determination of breaking strength and elongation (strip method)

ISO 13934-2:2014— Textiles – Tensile properties of fabrics – Part 2: Determination of breaking strength and elongation (grab method)

ISO 13935-1:2014— Textiles – Tensile properties of fabrics and their products – Part 1: Strength at joint breaking (strip method)

ISO 13935-2:2014—Textiles – Tensile properties of fabrics and their products – Part 2: Strength at joint breaking (sampling method)

ISO 13936-1:2004— Textiles – Determination of the slippage resistance of yarns at stitches in woven fabrics – Part 1: Fixed seam openings

ISO 13936-2:2004—Textiles – Determination of the slippage resistance of yarns at stitches in woven fabrics. Part 2: Fixed Load Method

ISO 13937-2:2000 —Textile materials. Tearing properties of fabrics. Part 2: Determination of tearing force of trouser specimens (single tear method)

ISO 13937-3:2000— Textile materials. Tearing properties of fabrics. Part 3: Determination of tearing force of airfoil specimens (single tearing method)

ISO 13937-4:2000 —Textile materials. Tearing properties of fabrics. Part 4: Determination of tearing force of lingual specimens (double tearing method)

ASTM D5034(2013)— Standard Test Method for Elongation and Breaking Strength of Textiles (Fabric Grasp Strength Test)

ASTM D5035(2015)—Test method for breaking strength and elongation of textiles (strip method)

ASTM D2261—-Determination of Tearing Strength (CRE) of Fabric by Single Tongue Method

ASTM D5587—-Tearing force of fabric was measured by trapezoidal method

ASTM D434—Standard measurement of resistance to joint slip

ASTM D1683-2007—Standard measurement of resistance to joint slip

BS4952— Elongation under specified load (bar pattern)

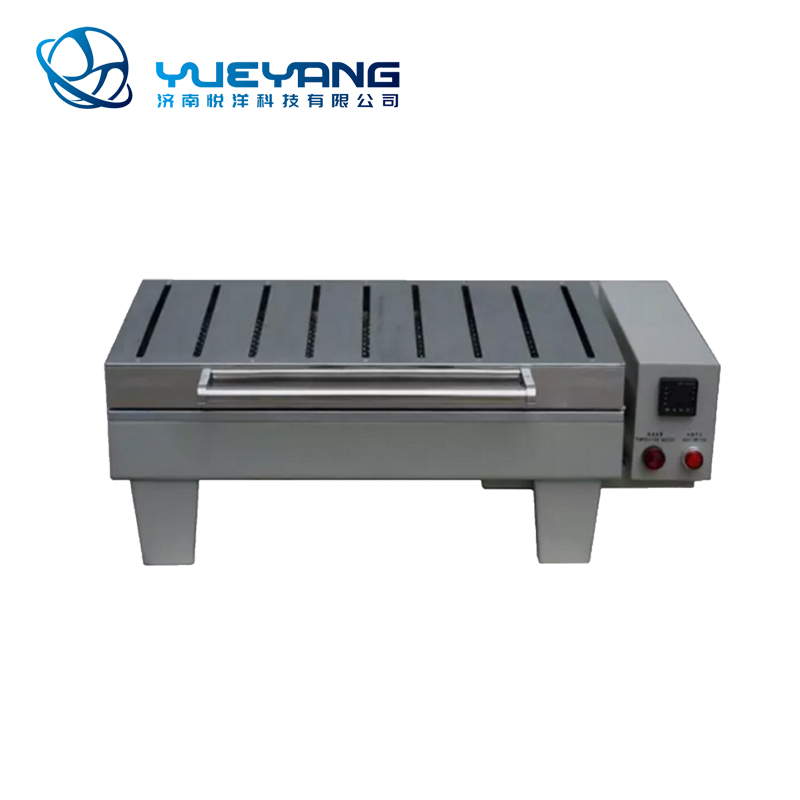

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for Excellent quality Textiles-Burning Behaviour-Vertical Method - YY026MG Electronic Tensile Strength Tester – Yueyang , The product will supply to all over the world, such as: Cairo, Paraguay, Ecuador, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!