Factory Outlets Sanitary Towel Absorbent Rate Tester - GC-7890 Ditert-butyl Peroxide Residue Detector – Yueyang

Factory Outlets Sanitary Towel Absorbent Rate Tester - GC-7890 Ditert-butyl Peroxide Residue Detector – Yueyang Detail:

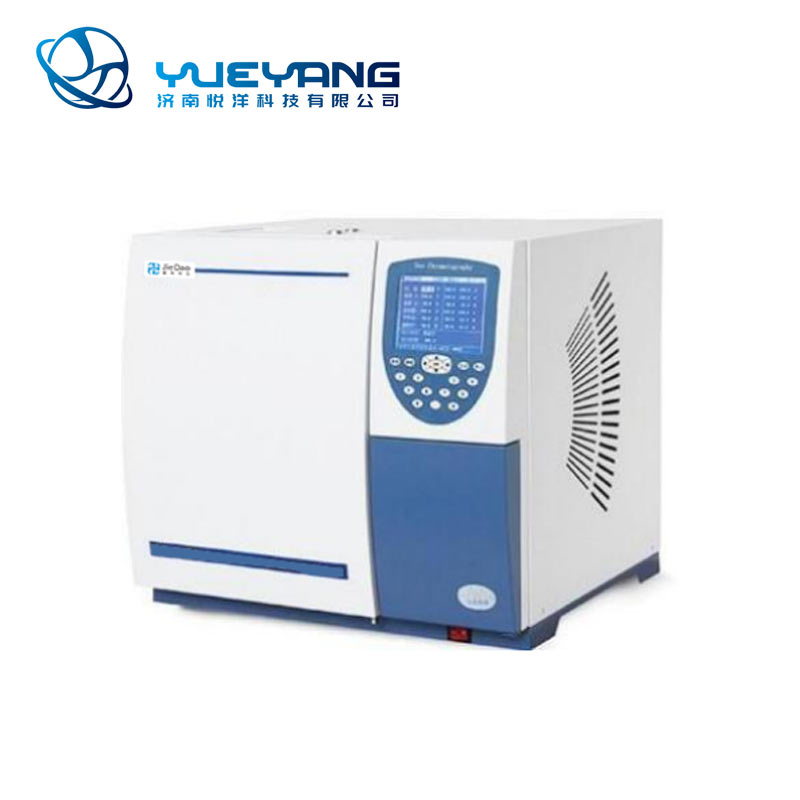

Melt-blown cloth has the characteristics of small pore size, high porosity and high filtration efficiency, and is the core material of mask production. This instrument refers to GB/T 30923-2014 plastic Polypropylene (PP) Melt-blown Special Material, suitable for polypropylene as the main raw material, with di-tert-butyl peroxide (DTBP) as the reducing agent, modified polypropylene melt-blown special material.

The sample is dissolved or swollen in toluene solvent containing a known amount of n-hexane as internal standard. An appropriate amount of solution was absorbed by microsampler and directly injected into gas chromatograph. Under certain conditions, gas chromatographic analysis was carried out. DTBP residue was determined by internal standard method.

1) Gas chromatograph, Capillary column inlet, FID detector,

2) Analyze the balance

3) Capillary column: AT.624 30m*0.32mm*1.8μm,

4) Chromatographic workstation software,

5) N-hexane, chromatographic pure;

6) Di-tert-butyl peroxide, analytically pure;

7) Toluene, analytical pure.

GC-7890 Gas chromatograph adopts microcomputer control system and Chinese large screen display, the appearance is more beautiful and smooth. The newly designed keyboard keys are simple and fast, and the circuits are imported components, so the instrument performance is stable and reliable.

Ⅰ. High circuit integration, high precision, multi-function

1. All-microcomputer key operation, 5.7 inch (320*240) large LCD display in Chinese and English, Chinese and English display can be switched freely, to meet the requirements of different groups of people, man-machine dialogue, easy to operate.

2.Microcomputer control hydrogen flame detector to achieve automatic ignition function, more intelligent. New integrated digital electronic circuit, high control precision, stable and reliable performance, up to 0.01℃ temperature control precision.

3.Gas protection function, protect the column and thermal conductivity pool, electron capture detector.

It has the function of self-diagnosis on startup, which enables users to quickly know the cause and position of instrument failure, stopwatch function (convenient flow measurement), power failure storage and protection function, anti-power mutation interference function, network data communication and remote control function. The overtemperature protection function is guaranteed

The instrument is not damaged and has a data memory system that does not require every reset.

Ⅱ.Injection system unique design, can be lower detection limit

1. Unique injection port design to solve injection discrimination; The double column compensation function not only solves the base-line drift caused by temperature programmed, but also subtracts the influence of background noise to obtain a lower detection limit.

2.With packed column, capillary shunt/non-shunt injection system (with diaphragm cleaning function)

3.Optional automatic/manual gas six-way injector, headspace injector, thermal resolution injector, methane converter, automatic injector.

Ⅲ、Temperature programmed, precise furnace temperature control, fast stability

1.Eight-order linear temperature programmed, after the door using photoelectric switch contactless design, reliable and durable, intelligent after the door system stepless variable air volume, shorten the program after the rise/drop of the detector system stable balance time, really realize the near room temperature operation, temperature control accuracy of ±0.01℃, meet the requirements of wide range of analysis.

2.Large volume of the column box, intelligent rear door system stepless variable air volume in and out, shorten the program after lifting/cooling the detector system stable balance time; Heating furnace system: ambient temperature +5℃ ~ 420℃.

3.The insulation effect is better: the column box, vaporization, detection are 300 degrees, the outer box and the top cover is less than 40 degrees, improve the experimental rate, to ensure the safety of the user.

4.Unique design of vaporization chamber, smaller dead volume; Accessories replacement: injection pad, liner, polarizer, collector, nozzle can be replaced with one hand; Main body replacement: filling column, capillary sampler and detector can be completely removed with only a wrench, easy maintenance.

High sensitivity, high stability detector, meet the needs of different schemes

Hydrogen flame ionization detector (FID), thermal conductivity cell detector (TCD), electron capture detector (ECD),

Flame Photometric detector (FPD), Nitrogen and Phosphorus detector (NPD)

All kinds of detectors can be independently controlled temperature, hydrogen flame detector is easy to disassemble and install, easy to clean or replace the nozzle.

Injection port

A variety of injection ports available: filled column injection, shunt/non-shunt capillary injection

Column temperature box

Temperature range: room temperature +5~420℃

Temperature setting: 1 degree; Programmed temperature rise rate 0.1 degree

Maximum heating rate: 40 degrees/min

Temperature stability: 0.01 degree when the ambient temperature changes 1 degree

Temperature programmed: 8 order temperature programmed can be adjusted

Hydrogen flame ionization detector (FID)

Operating temperature: 400℃

Detection limit: ≤5×10-12g/s (n-hexadecane)

Drift: 5 x 10-13 a / 30 min or less

Noise: 2 x or less 10 to 13 a

Dynamic linear range: ≥107

Size: 465*460*550mm, weight: 40kg,

Input power: AC220V 50HZ maximum power 2500W

Chemical industry, hospital, petroleum, winery, environmental inspection, food hygiene, soil, pesticide residues, paper making, electric power, mining, commodity inspection, etc.

Ethylene oxide testing instrument configuration table for medical instruments:

| Number |

Name |

Specifications |

number of |

|

1 |

Gas chromatograph |

GC-7890 Host (SPL+FID) |

1 |

|

2 |

Air generator |

2L |

1 |

|

3 |

Hydrogen generator |

300ml |

1 |

|

4 |

Nitrogen cylinders |

Purity: 99.999% Cylinder + pressure reducing valve (purchased locally) |

1 |

|

5 |

Dedicated column |

Capillary column |

1 |

|

6 |

The workstation |

N2000 |

1 |

|

|

|

|

Product detail pictures:

Related Product Guide:

To continually enhance the management technique by virtue of your rule of "sincerely, great faith and high-quality are the base of company development", we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for Factory Outlets Sanitary Towel Absorbent Rate Tester - GC-7890 Ditert-butyl Peroxide Residue Detector – Yueyang , The product will supply to all over the world, such as: Uruguay, Saudi Arabia, Angola, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.