Fiber&Yarn Testing Insturments

-

(China)YY238B Socks Wear Tester

Meet the standard:

EN 13770-2002 Determination of wear resistance of textile knitted shoes and socks — Method C.

-

(China)YY(B)512–Tumble-over pilling tester

[Scope] :

Used for testing the pilling performance of fabric under free rolling friction in drum.

[Relevant standards] :

GB/T4802.4 (Standard drafting unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc

【 Technical parameters 】 :

1. Box quantity: 4 PCS

2. Drum specifications: φ 146mm×152mm

3.Cork lining specification

452×146×1.5) mm

452×146×1.5) mm4. Impeller specifications: φ 12.7mm×120.6mm

5. Plastic blade specification: 10mm×65mm

6.Speed

1-2400)r/min

1-2400)r/min7. Test pressure

14-21)kPa

14-21)kPa8.Power source: AC220V±10% 50Hz 750W

9. Dimensions :(480×400×680)mm

10. Weight: 40kg

-

(China)YY215C Water Absorption Tester For Nonwovens & Towels

Instrument use:

The water absorption of towels on skin, dishes and furniture surface is simulated in real life to test

its water absorption, which is suitable for the test of water absorption of towels, face towels, square

towels, bath towels, towelettes and other towel products.

Meet the standard:

ASTM D 4772-97 Standard Test Method for Surface Water Absorption of Towel Fabrics (Flow Test Method),

GB/T 22799-2009 “Towel product Water absorption test Method”

-

(China)YY1006A Tuft Withdrawal Tensometer

Instrument use:

It is used to measure the force required to pull a single tuft or loop from a carpet, i.e. the binding force between the carpet pile and the backing.

Meet the standard:

BS 529:1975 (1996), QB/T 1090-2019, ISO 4919 Test method for pulling force of carpet pile.

-

(China)YY1000A Thickness Meter Static Loading

Instrument use:

Suitable for thickness testing of all woven carpets.

Meet the standard:

QB/T1089, ISO 3415, ISO 3416, etc.

Product features:

1, imported dial gauge, precision can reach 0.01mm.

-

(China)YY832 Multifunctional Sock Stretching Tester

Applicable standards:

FZ/T 70006, FZ/T 73001, FZ/T 73011, FZ/T 73013, FZ/T 73029, FZ/T 73030, FZ/T 73037, FZ/T 73041, FZ/T 73048 and other standards.

Product features:

1.Large screen color touch screen display and control, Chinese and English interface menu-type operation.

2. Delete any measured data and export the test results to EXCEL documents for easy connection

with the user’s enterprise management software.

3.Safety protection measures: limit, overload, negative force value, overcurrent, overvoltage protection, etc.

4. Force value calibration: digital code calibration (authorization code).

5. (host, computer) two-way control technology, so that the test is convenient and fast, the test results are rich and diverse (data reports, curves, graphs, reports).

6. Standard modular design, convenient instrument maintenance and upgrade.

7. Support online function, test report and curve can be printed out.

8. One total of four sets of fixtures, all installed on the host, can complete the socks straight extension and horizontal extension of the test.

9. The length of the measured tensile specimen is up to three meters.

10. With socks drawing special fixture, no damage to the sample, anti-slip, the stretching process of the clamp sample does not produce any form of deformation.

-

(China)YY571D AATCC Electric Crock Meter

Instrument use:

Used in textile, hosiery, leather, electrochemical metal plate, printing and other industries to evaluate

the color fastness friction test.

Meet the standard:

GB/T5712, GB/T3920, ISO105-X12 and other commonly used test standards, can be dry, wet friction

test function.

-

(China)YY501B Water Vapour Transmission Rate Tester

I.Instrument use:

Used for measuring moisture permeability of medical protective clothing, various coated fabrics, composite fabrics, composite films and other materials.

II.Meeting Standard:

1.GB 19082-2009 –Medical disposable protective clothing technical requirements 5.4.2 moisture permeability;

2.GB/T 12704-1991 —Method for determination of moisture permeability of fabrics – Moisture permeable cup method 6.1 Method A moisture absorption method;

3.GB/T 12704.1-2009 –Textile fabrics – Test methods for moisture permeability – Part 1: moisture absorption method;

4.GB/T 12704.2-2009 –Textile fabrics – Test methods for moisture permeability – Part 2: evaporation method;

5.ISO2528-2017—Sheet materials-Determination of water vaport transmission rate (WVTR)–Gravimetric(dish)method

6.ASTM E96; JIS L1099-2012 and other standards.

-

Scramble PillingYYZ01 Circle Sample Cutter

Used for sampling all kinds of fabrics and other materials; For measurement of fabric mass per unit area. GB/T4669;ISO3801;BS2471;ASTM D3776;IWS TM13. Model YYZ01A YYZ01B YYZ01C YYZ01F Remark Sampling Method Manual Manual Manual Electronic All aluminum alloy stamping molding Sampling diameter (area) ∮140mm ∮112.8mm(100cm2) ∮38mm ∮112.8mm(100cm2) The blade height is adjustable 0~5mm 0~5mm 0~5mm 0~5mm The thickness of the speci... -

(China)YY511B Fabric Density Mirror

Used for measurement of warp and weft density of all kinds of cotton, wool, hemp, silk, chemical fiber fabrics and blended fabrics. GB/T4668, ISO7211.2 1. Selected high quality aluminum alloy material manufacturing; 2. Simple operation, light and easy to carry; 3. Reasonable design and fine workmanship. 1. Magnification: 10 times, 20 times 2. Lens movement range: 0 ~ 50mm,0 ~ 2Inch 3. The ruler minimum indexing value: 1mm, 1/16inch 1.Host–1 Set 2.Magnifier Lens—10 times: 1 Pcs 3.M... -

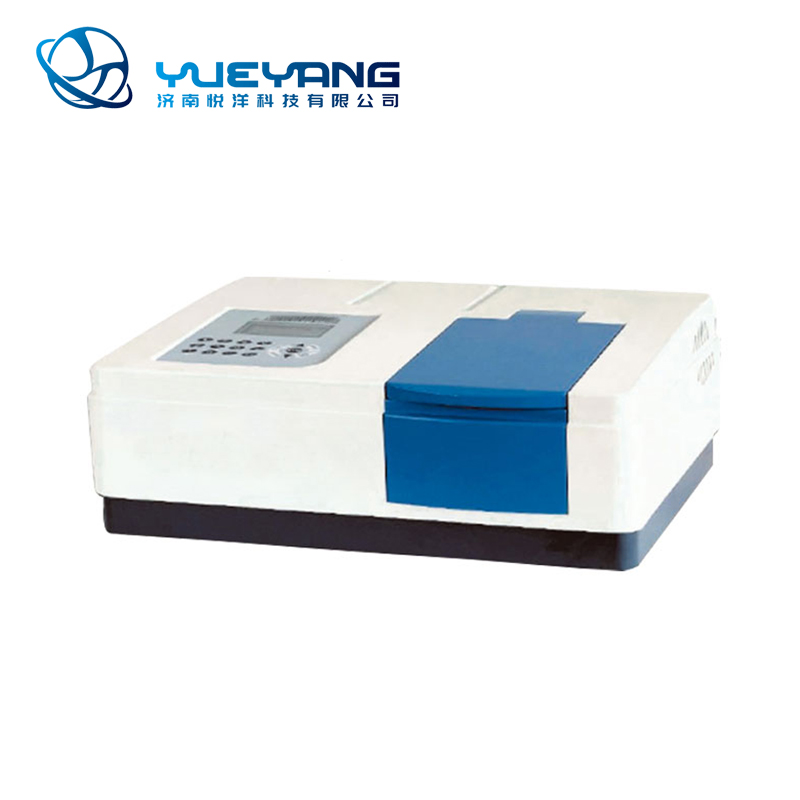

(China)YY201 Textile Formaldehyde Tester

Used for rapid determination of formaldehyde content in textiles. GB/T2912.1、GB/T18401、ISO 14184.1、ISO1 4184.2、AATCC112. 1. The instrument adopts 5″LCD graphic display and external thermal printer as display and output equipment, clearly display test results and prompts in the process of operation, thermal printer can easily print test results for data report and save; 2. The test method provides photometer mode, wavelength scanning, quantitative analysis, dynamic analysis and multi... -