Laboratory Furniture

-

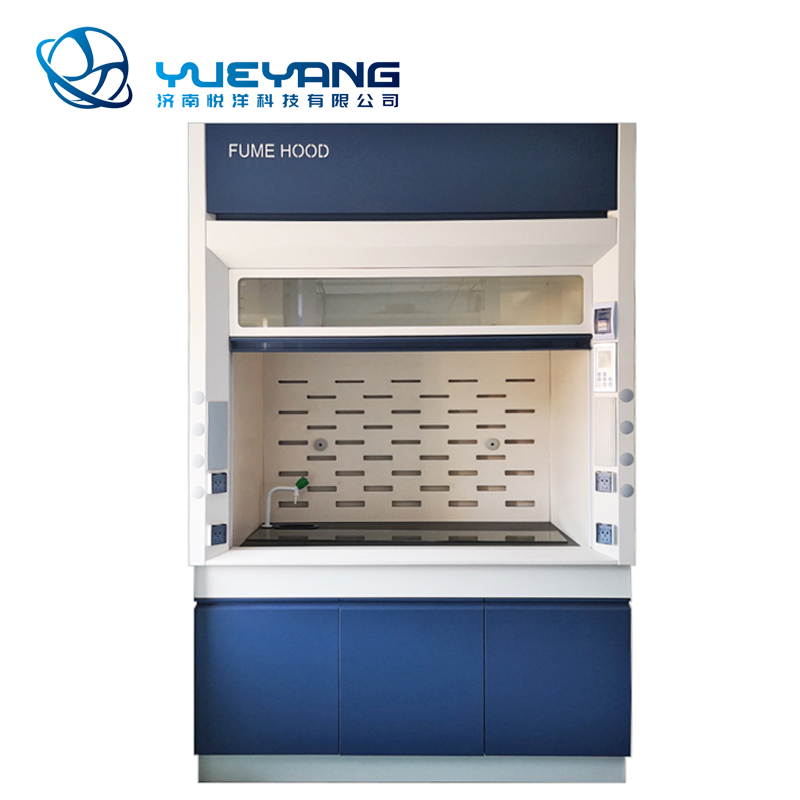

YYT1 Laboratory Fume Hood(PP)

Material description:

The disassembly and assembly structure of the cabinet adopts a “mouth shape, U shape, T shape” folded edge welded reinforcement structure, with a stable physical structure. It can bear a maximum load of 400KG, which is much higher than other similar brand products, and has excellent resistance to strong acids and alkalis. The lower cabinet body is made by welding 8mm thick PP polypropylene plates, which have extremely strong resistance to acids, alkalis and corrosion. All door panels adopt a folded edge structure, which is solid and firm, not easy to deform, and the overall appearance is elegant and generous.

-

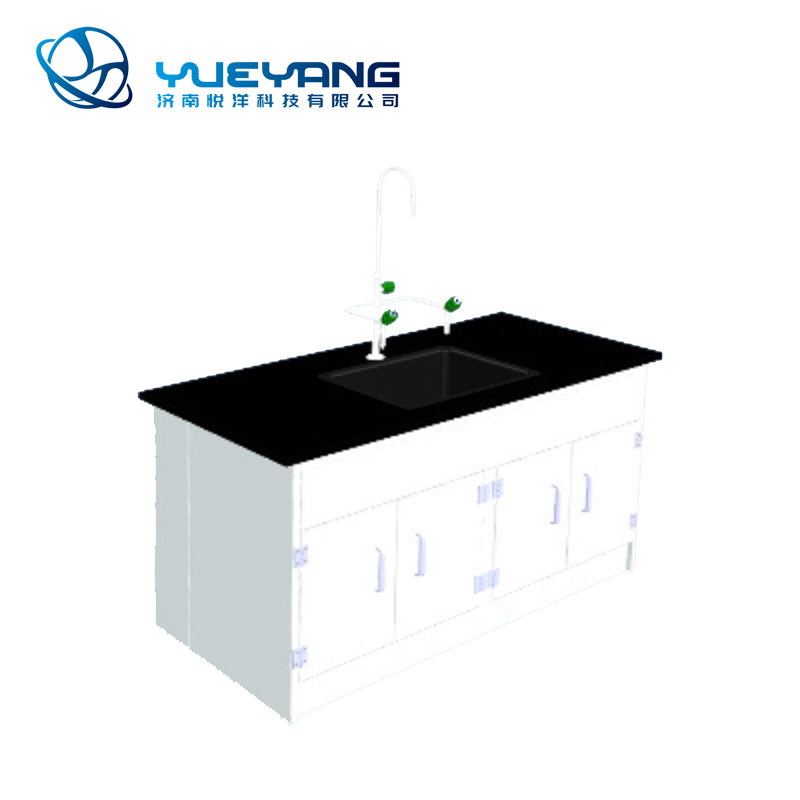

(China)Single Side Test Bench PP

Bench size can be customized; Make renderings for free.

-

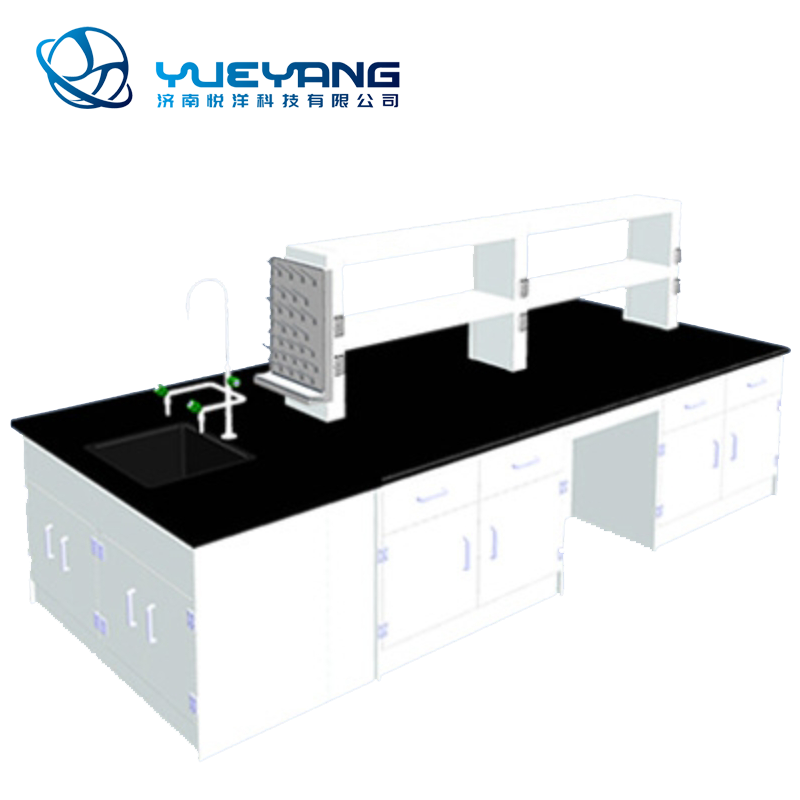

(China)Central Test Bench PP

Bench size can be customized; Make renderings for free.

-

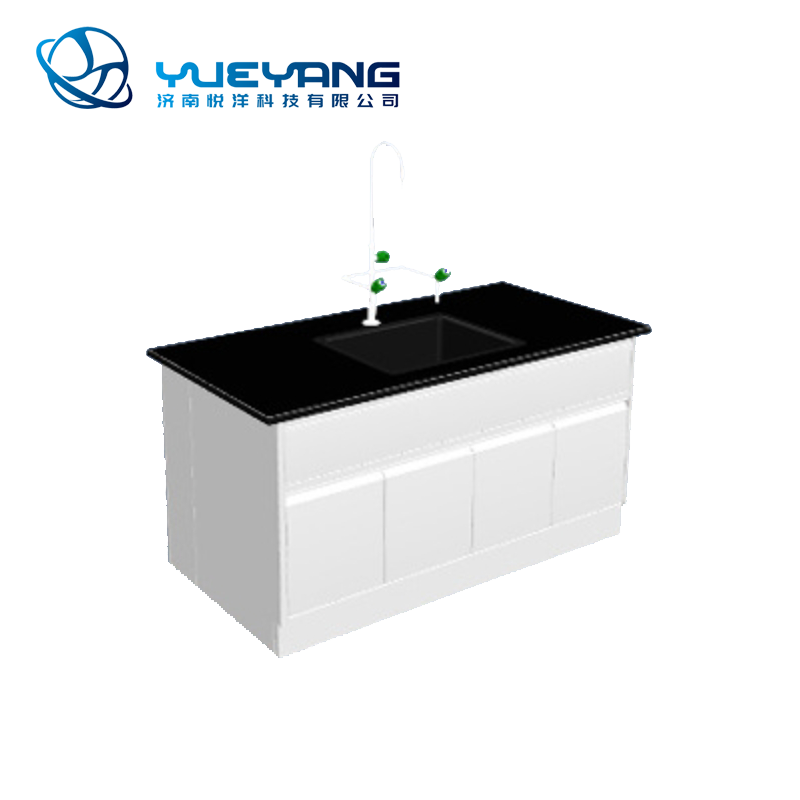

(China)Single Side Test Bench All Steel

Table top:

Using 12.7mm solid black physical and chemical board for the laboratory,

thickened to 25.4mm around, double-layer exterior garden along the edge,

acid and alkali resistance, water resistance, anti-static, easy to clean.

-

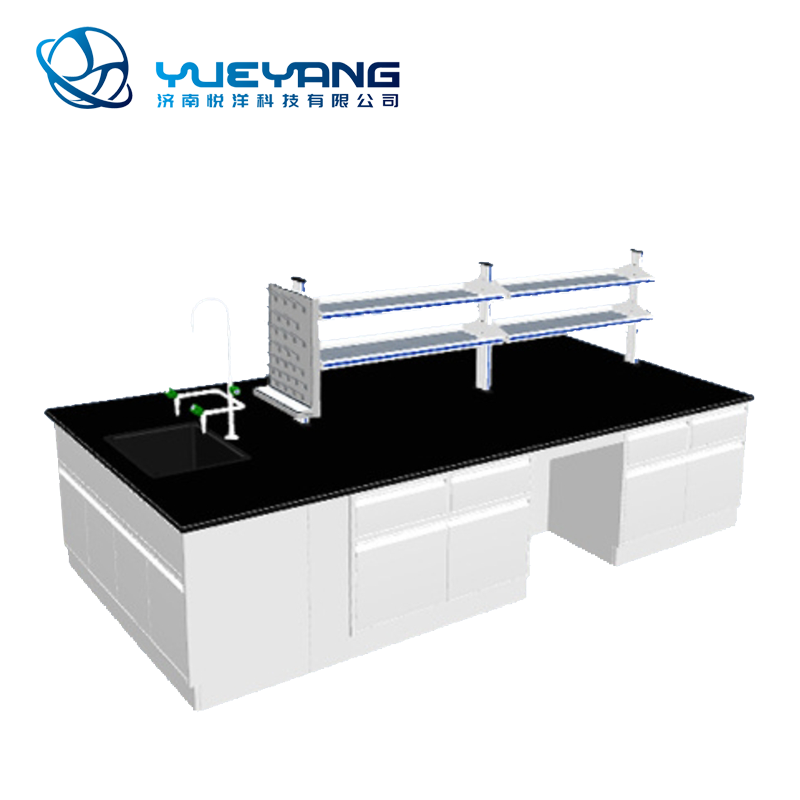

(China)Central Test Bench All Steel

Table top:

Using 12.7mm solid black physical and chemical board for the laboratory, thickened to 25.4mm

around, double-layer exterior garden along the edge, acid and alkali resistance,

water resistance, anti-static, easy to clean.

-

(China)Laboratory Fume Exhaust

Joint:

Adopts corrosion-resistant high-density PP material, can rotate 360 degrees to adjust the direction, easy to disassemble, assemble and clean

Sealing device:

The sealing ring is made of wear-resistant, corrosion-resistant and age-resistant high-density rubber and plastic material

Joint link rod:

Made of stainless steel

Joint tension knob:

The knob is made of corrosion-resistant high-density material, embedded metal nut, stylish and atmospheric appearance.

-

(China)YYT1 Laboratory Fume Hood

I.Material profile:

1. The main side plate, front steel plate, back plate, top plate and lower cabinet body can be made

of 1.0~1.2mm thick steel plate, 2000W imported from Germany

Dynamic CNC laser cutting machine cutting material, bending using automatic CNC bending

machine one at a time bending molding, the surface through epoxy resin powder

Electrostatic line automatic spraying and high temperature curing.

2. The lining plate and the deflector adopts 5mm thick core anti-double special plate with good

anti-corrosion and chemical resistance. The baffle fastener uses PP

High quality material production integrated molding.

3. Move the PP clamp on both sides of the window glass, handle PP into one body, embed 5mm tempered glass, and open the door at 760mm.

Free lifting, sliding door up and down sliding device adopts pulley wire rope structure, stepless

arbitrary stay, sliding door guide device by anti-corrosion polymerization

Made of vinyl chloride.

3. The fixed window frame is made of epoxy resin spraying of steel plate, and 5mm thick tempered glass is embedded in the frame.

4. The table is made of (domestic) solid core physical and chemical board (12.7mm thick) acid and alkali resistance, impact resistance, corrosion resistance, formaldehyde reaches E1 level standards.

5. All the internal connection devices of the connection part need to be hidden and corrosion

resistant, there are no exposed screws, and the external connection devices are resistant

Corrosion of stainless steel parts and non-metallic materials.

6. The exhaust outlet adopts an integrated air hood with the top plate. The diameter of the outlet

is 250mm round hole, and the sleeve is connected to reduce the gas disturbance.