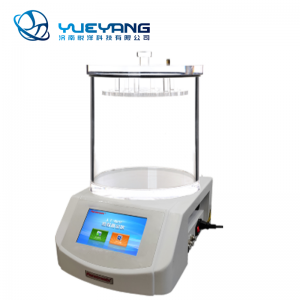

(China)PL7-C Type Flat Paper Sample Quick Dryer

PL7-C flat-plate paper sample quick dryer, can be used with PL6 series sheet machine and former without vacuum drying, dry evenly, smooth surface and long service life, can be heated for a long time, mainly used for fiber and other flakes drying of the samples.

The red integrated heating plate is used to transmit heat to the surface, and the surface is dried by stainless steel. The upper cover plate is pressed down vertically, and the pattern is uniformly stressed, heated evenly, and shiny. It is a pattern drying equipment that requires high accuracy of pattern detection data.

The heating surface of the drying surface is finely ground, and the upper cover is made of breathable and heat-resistant fiber, weighing 23Kg.

Digital temperature control, can be heated for a long time.

Full size distribution of heating elements.

Heating power: 1.5KW/220V

Pattern thickness: 0~15mm

Dry size: 600mm×350mm

Net size: 660mm×520mm×320mm

Ⅱ.The heating temperature Settings

We've already set the XMT612 intelligent temperature control instrument,it can be used directly.Temperature control is temporarily set at 100 ℃.When using open the power switch,Instrument electricity.The red PV show temperature.The green SV show the set.Press the heating switch make the red button self-locking.after 5-8 seconds,it Slowly start heating.after 1-2 minutes,Full power heating.When heating temperature approach the set temperature,Heating lamp flicker.

Instrument for the equipment is PID Intelligent control temperature control instrumen.if set temperature again.Simply press the ∧ or ∨ key.

If the control accuracy is not ideal, or is affected by climate change on the room temperature, can also cause control accuracy is bad.Can use the instrument Self-tuning function.Operating methods:Long press > more than 3 seconds until the AT lights flashing.Instrument began self-tuning PID parameters calculation.Time range from a few minutes to several hours.only need start once.

Adjustment method of parameter

1.Temperature control:In working status, press increases, reducing directly.

2.Adjust the heating speed:press the ‘set’and enter the password:0036.Reduce the P value, heating quickly (increase P values, slow heating).

3.Manual control:Long 4 seconds press SET key, the AT/M light normally on, enter a state of the manual,At this time press increase and decrease,Instrument in accordance with the time proportion of output,SV window display output percentage.Long press set key,AT/M lights off, exit status manually.

Ⅲ.Over temperature alarm

Before leaving the factory, the machine is set to a temperature of 100 ℃, and overtemperature alarm set at a temperature of 120 ℃.When the temperature reaches 120 ℃ alarm, the alarm will automatically alarm.When the temperature drops below the alarm set point temperature 3 ℃, the alarm will automatically stop the alarm.

Adjust the alarm temperature:press set button and enter the password 0001.and then adjust AH1 value, AH2 value.

If you noticed the Temperature controller can not Control the temperature,The temperature only go up,can check the solid-state relay.If you noticed No heat or temperature rise,can check The heating plate bad or not.

Ⅳ.Operation method

Turn on the power switch,the instrument is powered, press the heating switch make the red button latching 5-8 seconds,and after that,start heating slowly.(Heating lamp blinks from weak to strong).1-2 minutes at full power heating,The red light no longer flashes(Red light heating, Otherwise means stop off heating).When the heating temperature is approach the set temperature.Heating light starts blinking,Automatic control constant temperature.

When drying wet paper. You can wet paper sandwiched by two plain cloth, holding a cloth edge together into the device, to prevent causing wet paper fracture, wrinkling, deformation,

The device cover weight 23kg, when dry will reduce or prevent shrinkage dried to make dried sheet flat and smooth.The equipment failure rate is very low,It can be used continuously for a long time.after work must dry the felt which on the cover.Heating panel need to dry.

If you find malfunction when using.We must first find the causes of power failures and then open the electronic control box,Check or replace fuse corresponding model specification.