Plastic Testing Instruments

-

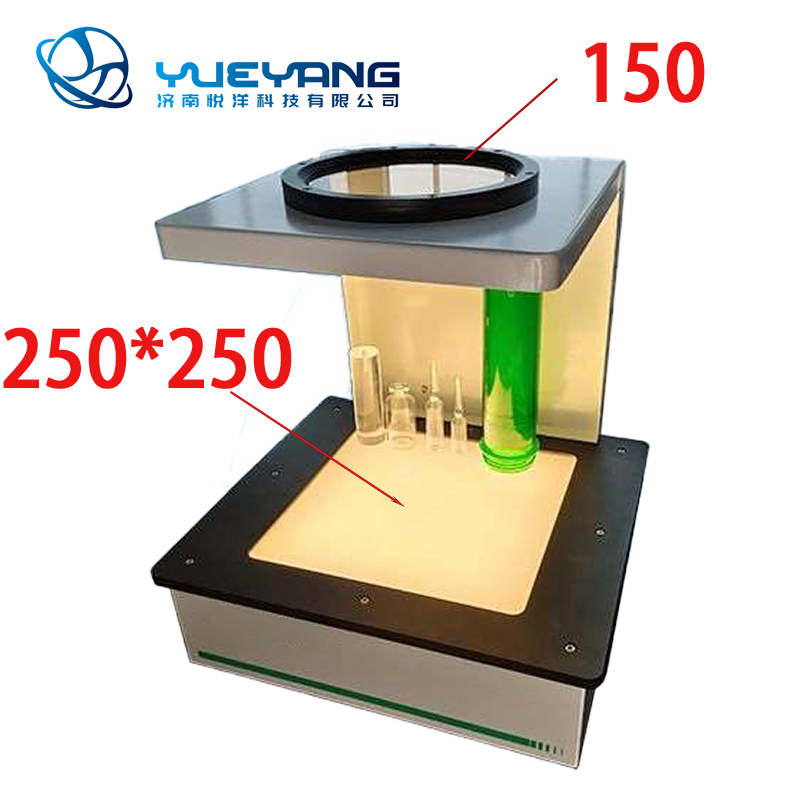

(China)YYPL03 Polariscope Strain Viewer

YYPL03 is a test instrument developed according to the standard《 GB/T 4545-2007 Test method for internal stress in glass bottles》, which is used to test the annealing performance of glass bottles and glass products and analyze the internal stress of

products.

-

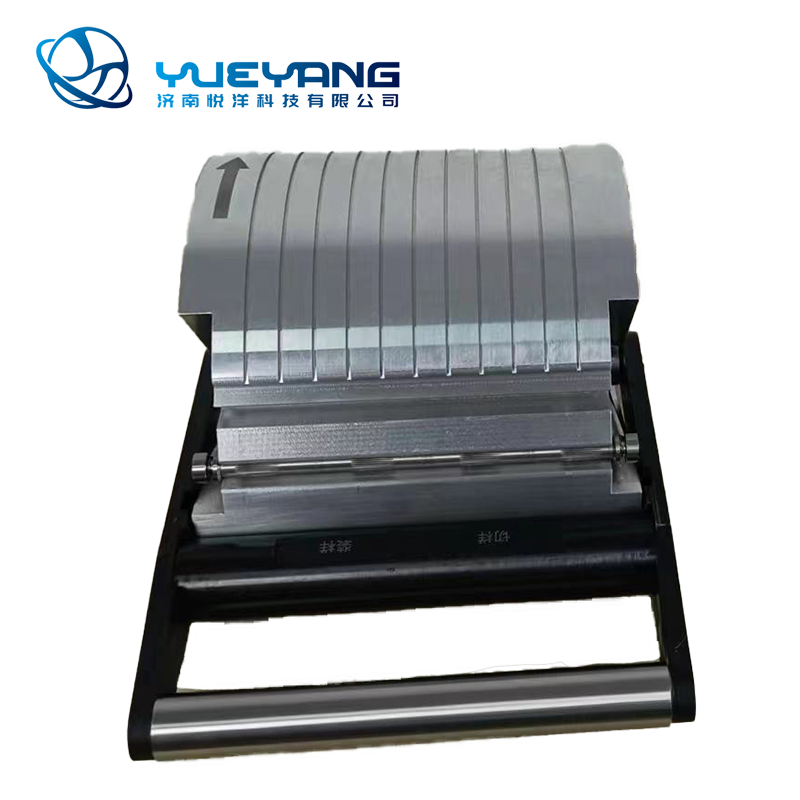

(China)YYP 114E Stripe Sampler

This machine is suitable for cutting straight strip samples of bidirectional stretched film, unidirectional stretched film and its composite film, in line with

GB/T1040.3-2006 and ISO527-3:1995 standard requirements. The main feature

is that the operation is convenient and simple, the edge of the cut spline is neat,

and the original mechanical properties of the film can be maintained.

-

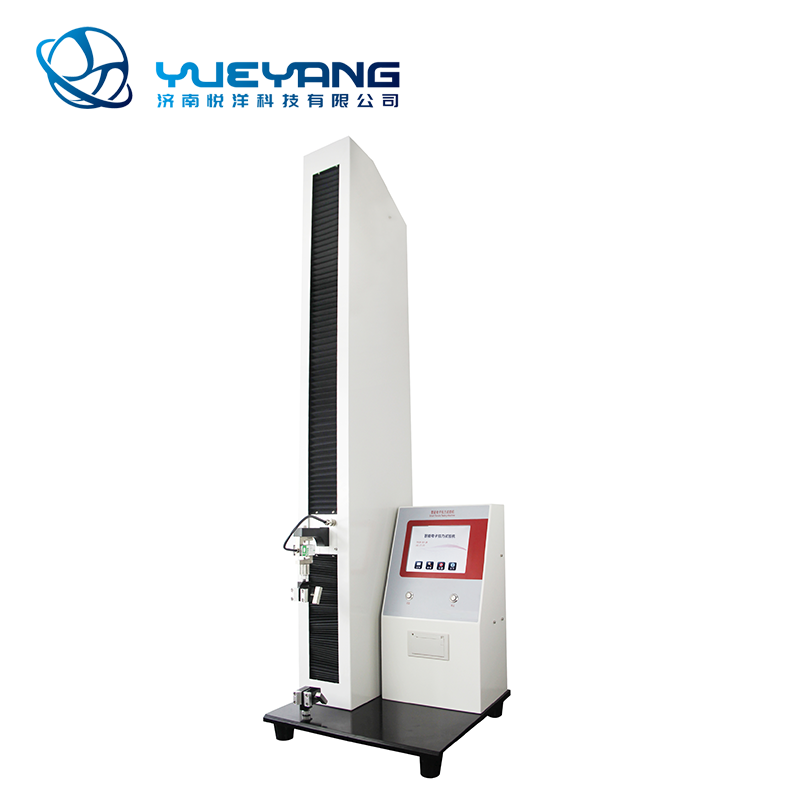

(China)YYP101 Universal Tensile Testing Machine

Technical characteristics:

1.The 1000mm ultra-long test journey

2.Panasonic Brand Servo Motor Testing System

3.American CELTRON brand force measurement system.

4.Pneumatic test fixture

-

(China)YYP-50D2 Simply Supported Beam Impact Tester

Executive standard: ISO179, GB/T1043, JB8762 and other standards. Technical parameters and indicators: 1. Impact speed (m/s): 2.9 3.8 2. Impact energy (J): 7.5, 15, 25, (50) 3. Pendulum angle: 160° 4. Corner radius of impact blade: R=2mm ±0.5mm 5. Jaw fillet radius: R=1mm ±0.1mm 6. The included angle of the impact blade: 30°±1° 7. Jaw spacing: 40mm, 60mm, 70mm, 95mm 8. Display mode: LCD Chinese/English display (with automatic energy loss correction function and storage of historical ... -

(China)YYP-50 Simply Supported Beam Impact Tester

It is used to determine the impact strength (simply supported beam) of non-metallic materials such as rigid plastics, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic electrical appliances, and insulating materials. Each specification and model has two types: electronic type and pointer dial type: the pointer dial type impact testing machine has the characteristics of high precision, good stability and large measurement range; the electronic impact testing machine adopts the circular grating angle measurement technology, except for In addition to all the advantages of the pointer dial type, it can also digitally measure and display the breaking power, impact strength, pre-elevation angle, lift angle, and the average value of a batch; it has the function of automatic correction of energy loss, and can store 10 sets of historical data information. This series of testing machines can be used for simply supported beam impact tests in scientific research institutions, colleges and universities, production inspection institutes at all levels, material production plants, etc.

-

YYP-22 Izod Impact Tester

It is used to determine the impact strength (Izod) of non-metallic materials such as rigid plastics, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic electrical appliances, insulating materials, etc. Each specification and model has two types: electronic type and pointer dial type: the pointer dial type impact testing machine has the characteristics of high precision, good stability and large measurement range; the electronic impact testing machine adopts the circular grating angle measurement technology, except for In addition to all the advantages of the pointer dial type, it can also digitally measure and display the breaking power, impact strength, pre-elevation angle, lift angle, and the average value of a batch; it has the function of automatic correction of energy loss, and can store 10 sets of historical data information. This series of testing machines can be used for Izod impact tests in scientific research institutions, colleges and universities, production inspection institutes at all levels, material production plants, etc.

-

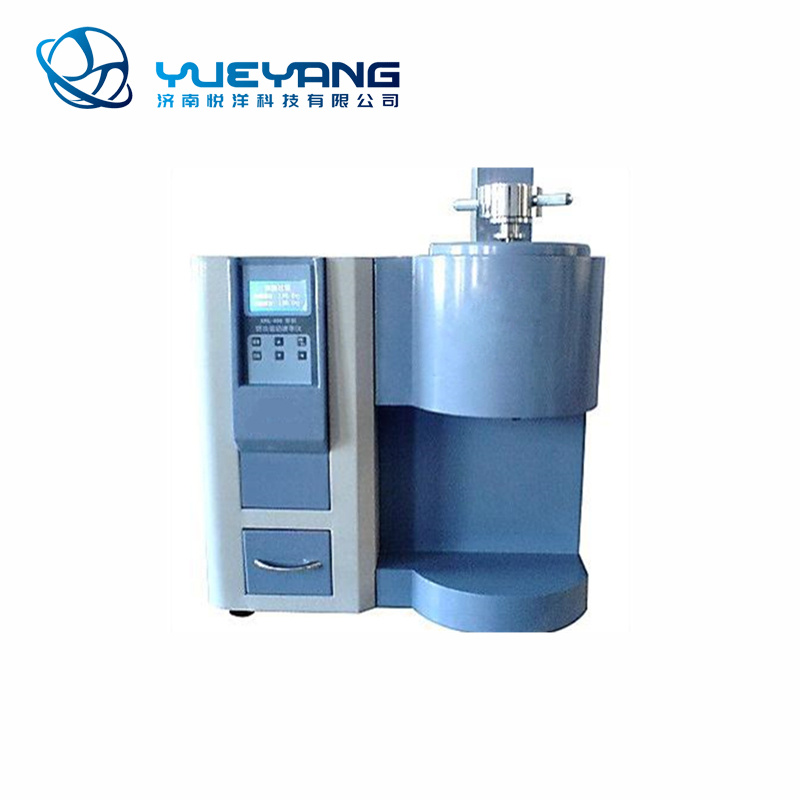

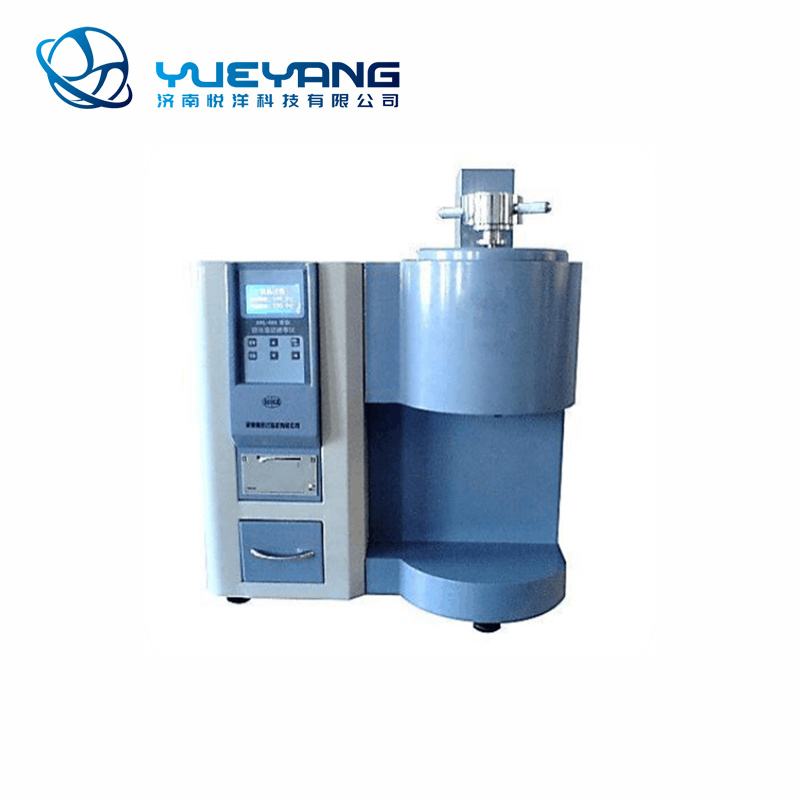

YYP-400A Melt Flow Indexer

Melt flow indexer is used to characterize the flow performance of thermoplastic polymer in the viscous state of the instrument, used to determine the melt mass flow rate (MFR) and melt volume flow rate (MVR) of thermoplastic resin, both suitable for high melting temperature of polycarbonate, nylon, fluorine plastic, polyaromatic sulfone and other engineering plastics, Also suitable for polyethylene, polystyrene, polypropylene, ABS resin, polyformaldehyde resin and other plastic melting temper... -

(China)YYP-400B Melt Flow Indexer

Melt flow indexer is used to characterize the flow performance of thermoplastic polymer in the viscous state of the instrument, used to determine the melt mass flow rate (MFR) and melt volume flow rate (MVR) of thermoplastic resin, both suitable for high melting temperature of polycarbonate, nylon, fluorine plastic, polyaromatic sulfone and other engineering plastics, Also suitable for polyethylene, polystyrene, polypropylene, ABS resin, polyformaldehyde resin and other plastic melting temper... -

(China)YYP-800D Digital Display Shore Hardness Tester

YYP-800D high precision digital display shore/Shore hardness tester (shore D type), it is mainly used for measuring hard rubber, hard plastics and other materials. For example: thermoplastics, hard resins, plastic fan blades, plastic polymer materials, acrylic, Plexiglass, UV glue, fan blades, epoxy resin cured colloids, nylon, ABS, Teflon, composite materials, etc. Comply with ASTM D2240, ISO868, ISO7619, GB/T2411-2008 and other standards. HTS-800D (Pin size) (1) Built-in high precision dig... -

(China)YY026H-250 Electronic Tensile Strength Tester

This instrument is the domestic textile industry powerful test configuration of high-grade, perfect function, high precision, stable and reliable performance model. Widely used in yarn, fabric, printing and dyeing, fabric, clothing, zipper, leather, nonwoven, geotextile and other industries of breaking, tearing, breaking, peeling, seam, elasticity, creep test.

-

YYP-JM-720A Rapid Moisture Meter

Main Technical Parameters:

Model

JM-720A

Maximum weighing

120g

Weighing precision

0.001g(1mg)

Non-water electrolytic analysis

0.01%

Measured data

Weight before drying, weight after drying, moisture value, solid content

Measuring range

0-100% moisture

Scale size(mm)

Φ90(stainless steel)

Thermoforming Ranges(℃)

40~~200(increasing temperature 1°C)

Drying procedure

Standard heating method

Stop method

Automatic stop, timing stop

Setting time

0~99分 1 Minute interval

Power

600W

Power Supply

220V

Options

Printer /Scales

Packaging Size(L*W*H)(mm)

510*380*480

Net Weight

4kg

-

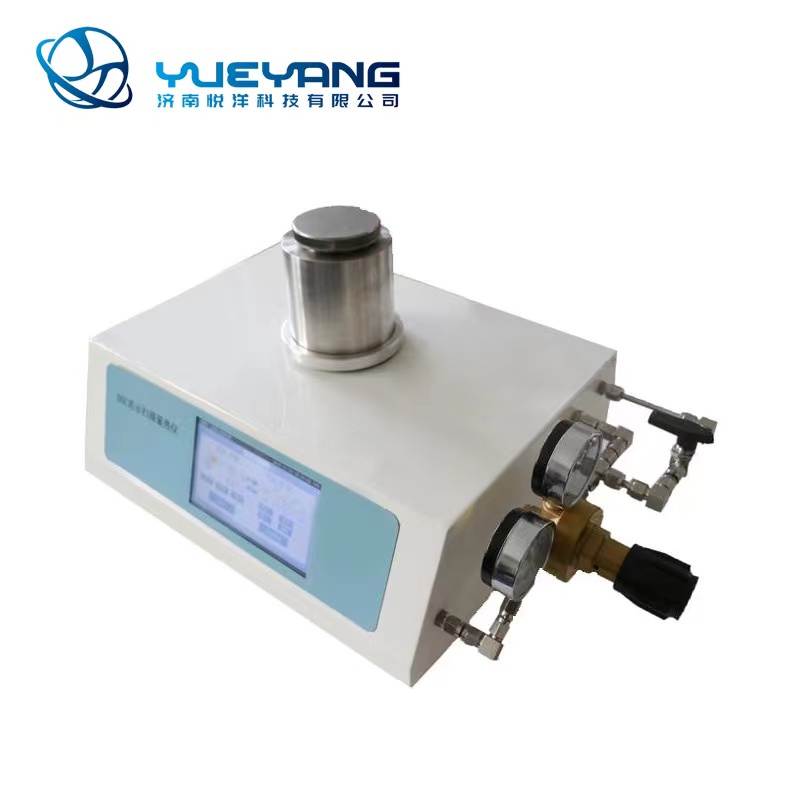

YYP-HP5 Differential scanning calorimeter

Parameters:

- Temperature range: RT-500℃

- Temperature resolution:0.01℃

- Pressure range: 0-5Mpa

- Heating rate: 0.1~80℃/min

- Cooling rate: 0.1~30℃/min

- Constant temperature: RT-500℃,

- Duration of constant temperature: The duration is recommended to be less than 24 hours.

- DSC range: 0~±500mW

- DSC resolution: 0.01mW

- DSC sensitivity: 0.01mW

- Working power: AC 220V 50Hz 300W or other

- Atmosphere control gas: Two-channel gas control by automatic controlled (e.g. nitrogen and oxygen)

- Gas flow:0-200mL/min

- Gas pressure:0.2MPa

- Gas flow accuracy: 0.2mL/min

- Crucible: Aluminium crucible Φ6.6*3mm (Diameter * High)

- Data interface: Standard USB interface

- Display mode: 7-inch touch screen

- Output mode: computer and printer