Products

-

YYPL28 Vertical Standard Pulp Disintegrator

PL28-2 vertical Standard Pulp Disintegrator, Another name is standard fiber dissociation or Standard fiber blender, Pulp fiber raw material at high speed in the water, Bundle fiber dissociation of single fiber. It is used to making sheethand, measure filter degree, The preparation for pulp screening.

-

YY6000A Glove Cutting Resistance Tester

Used for testing the strength of protective gloves and uppers. Color touch screen display control, menu operation mode.

-

YY-24E Colour Fastness To Washing Tester(24 Cups)

Used for testing color fastness to washing and dry cleaning of various cotton, wool, hemp, silk and chemical fiber textiles.

-

(China)YYP-JM-720A Rapid Moisture Meter

Widely used in various industries such as plastics, food, feed, tobacco, paper, food (dehydrated vegetables, meat, noodles, flour, biscuit, pie, aquatic processing), tea, beverage, grain, chemical raw materials, pharmaceutical, textile raw materials and so on, to test the free water contained in the sample

-

YY086 Sample Skein Winder

Used for testing the linear density (count) and wisp count of all kinds of yarns.

-

AATCC Standard Dryer–YY4815FW

Used for printing and dyeing, clothing industry to complete the American standard shrinkage test.

-

YY003–Button Color Fastness Tester

Used for testing the color fastness and ironing resistance of buttons.

-

YY747A Fast Eight Basket Constant Temperature Oven

YY747A type eight basket oven is the upgrading product of YY802A eight basket oven, which is used for the rapid determination of moisture regain of cotton, wool, silk, chemical fiber and other textiles and finished products; Single moisture return test only takes 40 minutes, effectively improving the work efficiency.

-

YY743 Roll Dryer

Used for drying all kinds of textiles after shrinkage test.

-

YY6002A Glove Cutting Resistance Tester

Used to evaluate the cutting resistance of glove.

-

YY-32F Colour Fastness To Washing Tester(16+16 cups)

Used for testing color fastness to washing and dry cleaning of various cotton, wool, hemp, silk and chemical fiber textiles.

-

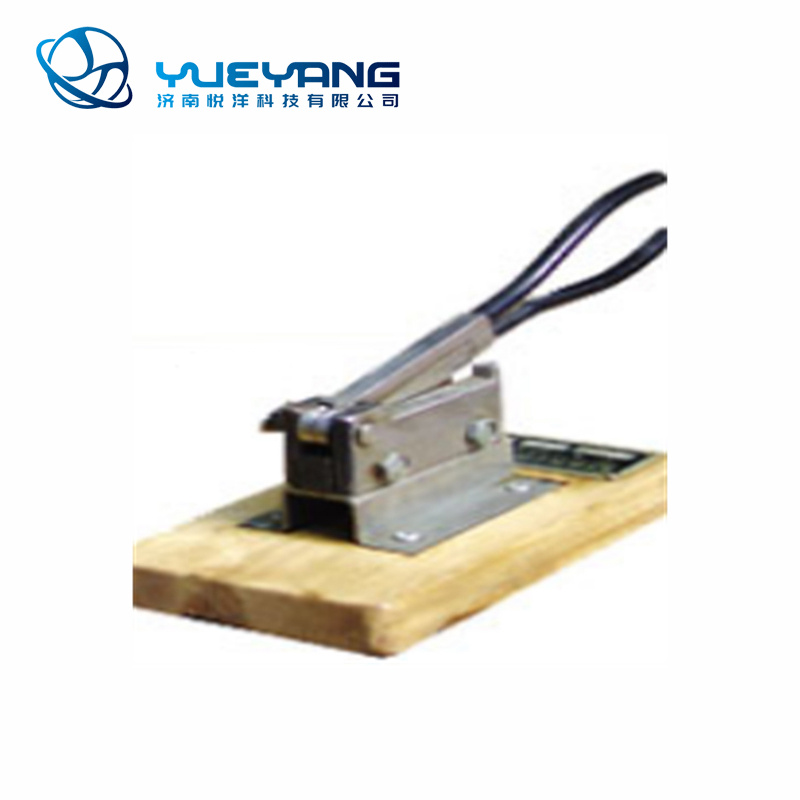

YY171A Fibre Specimen Cutter

Fibers of a certain length are cut and used to measure fiber density.

-

YY-6A Dry Washing Machine

Used for the determination of physical index changes such as appearance color, size and peel strength of clothing and various textiles after dry cleaning with organic solvent or alkaline solution.

-

YY101A–Integrated Zipper Strength Tester

Used for zipper flat pull, top stop, bottom stop, open end flat pull, pull head pull piece combination, pull head self-lock, socket shift, single tooth shift strength test and zipper wire, zipper ribbon, zipper sewing thread strength test.

-

YY802A Eight Baskets Constant Temperature Oven

Used for drying all kinds of fibers, yarns, textiles and other samples at constant temperature, weighing with high-precision electronic balance; It comes with eight ultra-light aluminum swivel baskets.

-

YY211A Far infrared Temperature Rise Tester For Textiles

Used for all kinds of textile products, including fibers, yarns, fabrics, nonwovens and their products, testing the far infrared properties of textiles by temperature rise test.

-

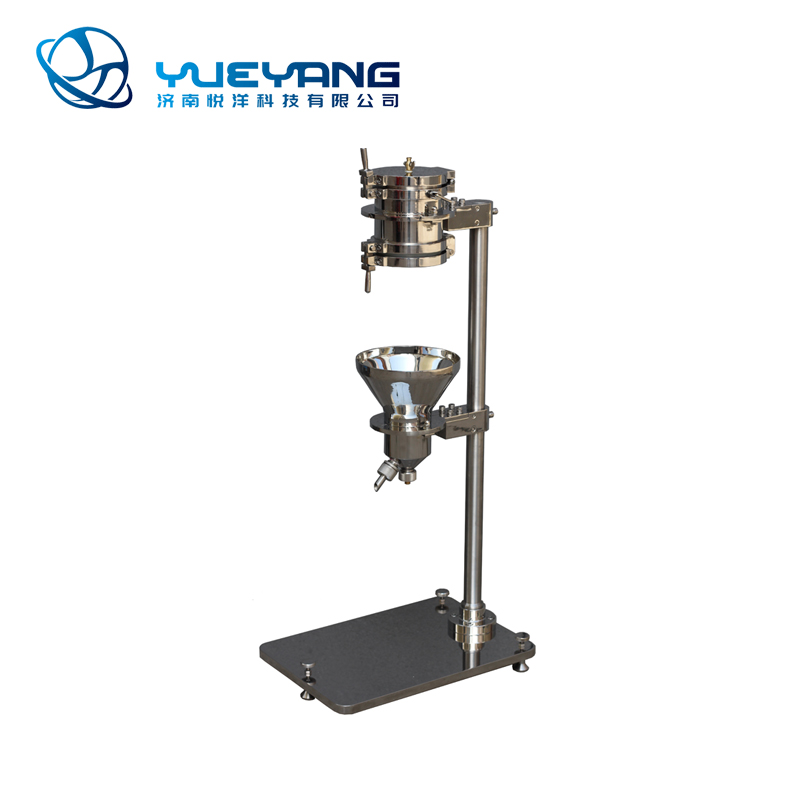

(China)YYP116-2 Canadian Standard Freeness Tester

Canadian Standard Freeness Tester is used for the determination of water filtration rate of water suspensions of various pulp, and expressed by the concept of freeness (CSF).The filtration rate reflects how the fibers are after pulping or finely grinding.Standard freeness measuring instrument is widely used in the pulping process of paper making industry, the establishment of paper making technology and various pulping experiments of scientific research institutes.

-

YY6003A Glove Insulation Tester

Used to test the heat insulation performance of the heat insulation material at the moment when it is in contact with high temperature.

-

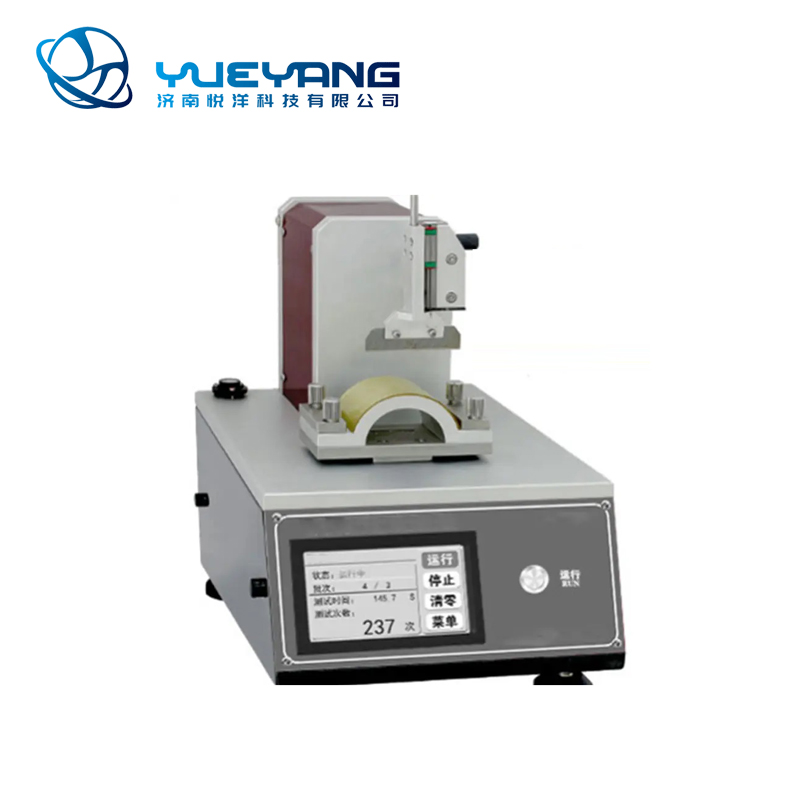

YY-60A Friction Colour Fastness Tester

Instruments used for testing the colour fastness to friction of various coloured textiles are rated according to the colour staining of the fabric on which the rub head is attached.

-

YYP-LC-300B Drop Hammer Impact Tester

LC-300 series drop hammer impact testing machine using double tube structure, mainly by the table, prevent secondary impact mechanism, hammer body, lifting mechanism, automatic drop hammer mechanism, motor, reducer, electric control box, frame and other parts. It is widely used for measuring the impact resistance of various plastic pipes, as well as the impact measurement of plates and profiles. This series of testing machines are widely used in scientific research institutions, colleges and universities, quality inspection departments, production enterprises to do drop hammer impact test.