Quality Inspection for Smelting Point Instrument - YYP135 Falling Dart Impact Tester – Yueyang

Quality Inspection for Smelting Point Instrument - YYP135 Falling Dart Impact Tester – Yueyang Detail:

YYP135 Falling Dart Impact Tester is applicable in the impact result and energy measurement of the falling dart from a certain height against plastic films and sheets with thickness less than 1mm, which would result in 50% tested specimen failure.

1. Mechanical modelling novel, considerate operation design;

2. Comply with international standard and national standard both;

3. Two test methods integration: A & B. easy to use;

4. Electric gripped sample;

5. Micro computer processing experimental data, the intelligent experimental process, greatly improving the work efficiency;

It is applicable to test the impact resistance properties of plastic film, sheet, composite film, with thickness less than 1mm, such as plastic wrap, stretch film, PET sheet, different food packaging bags, heavy bags, aluminum foil, aluminum compound packing film, paper and cardboard, etc.

At the beginning of the test, choose test method, and estimate an initial mass and Δm. Start test. If the first specimen fails, decrease the mass of the falling dart by decreasing weight of Δm. If the first specimen is not a failure, add the mass of the falling dart by increasing weight of Δm. Test as the same. In brief, increase or decrease the Δm according to whether the former specimen is a failure or not. After 20 specimens, calculate the total number of failure specimens N. If N equals to 10, test over. If N is less than 10, add specimen and continue to test until N is equal to 10. If N is more than 10, add specimen and continue the test until the number of non-failure specimen is 10. Then the tester calculates the test results automatically according to special formula.

It complies with standards ASTM D1709, ISO 7765, JIS K7124, GB 9639.

| Items | Parameter |

| Test Method | A, B (Optional) |

| Test Range | Method A: 50~2000g Method B: 300~2000g |

| Test Accuracy | 0.1g (0.1J) |

| Specimen Size | >150mm×150mm |

| Power | AC 220V 50Hz |

| Net Weight | 60kg |

Standard: method A configuration, mini-printer, communication cable

Optional: method B configuration, mini-printer, communication cable

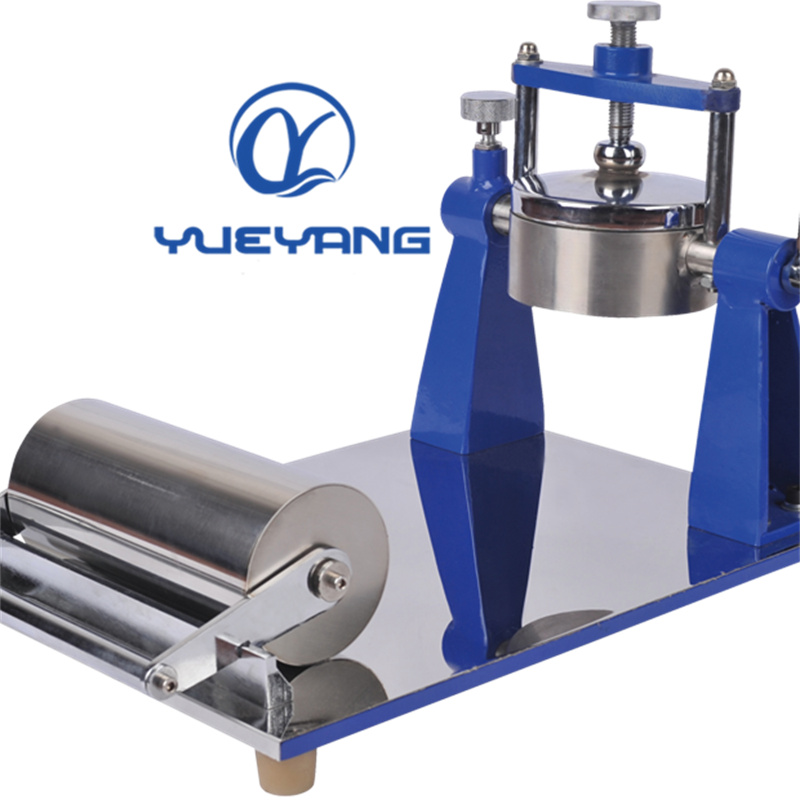

Product detail pictures:

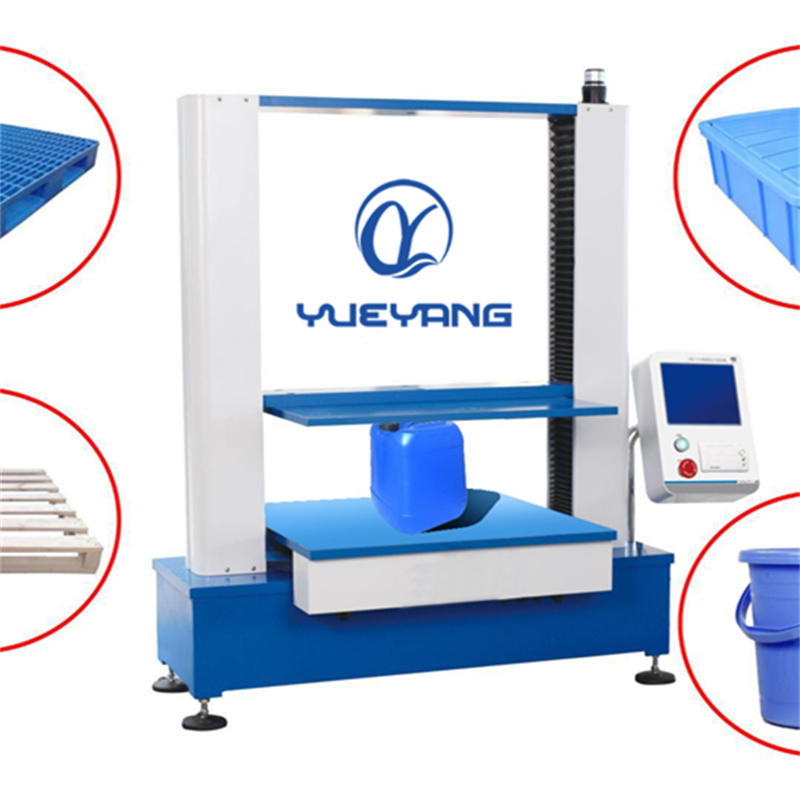

Related Product Guide:

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Quality Inspection for Smelting Point Instrument - YYP135 Falling Dart Impact Tester – Yueyang , The product will supply to all over the world, such as: Lebanon, Kuala Lumpur, Madrid, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.