Quality Inspection for Transmittance: 0.1 % - YY311 Water Vapor Transmission Rate Tester (infrared method) – Yueyang

Quality Inspection for Transmittance: 0.1 % - YY311 Water Vapor Transmission Rate Tester (infrared method) – Yueyang Detail:

YY311 water vapor transmission rate tester (infrared method), the instrument is suitable for the determination of water vapor transmission rate of plastic films, composite films and other films and sheet materials. Through the measurement of water vapor transmission rate, the technical indicators of control and adjustment of packaging materials and other products can be achieved to meet the different needs of product applications.

ASTM F1249、ISO 15106-2、TAPPI T557

1. Three chambers can simultaneously measure the water vapor transmission rate of the sample;

2. The three test chambers are completely independent and can test three identical or different samples at the same time;

3. Wide-range, high-precision temperature and humidity control, to meet the test under various test conditions;

4. The system adopts computer control, and the whole test process is completed automatically

5. Equipped with USB universal data interface to facilitate data transfer;

6. The software follows the principle of GMP authority management, and has functions such as user management, authority management, and data audit tracking.

The pretreated sample is clamped between the test chambers, nitrogen with a certain relative humidity flows on one side of the film, and dry nitrogen flows on the other side of the film. Due to the existence of the humidity gradient, water vapor will pass through the high humidity side. Diffusion through the film to the low-humidity side. On the low-humidity side, the permeated water vapor is carried to the sensor by the flowing dry nitrogen. When entering the infrared sensor, different spectral signals will be generated. Through the analysis and calculation of the different spectral signals, the sample is obtained. parameters such as water vapor transmission rate.

Test range: 0.01~40 g/(m2·24h)

Resolution: 0.01 g/m2 24h

Number of samples: 3 pieces (independently)

Sample size: 100mm×110mm

Test area: 50cm2

Sample thickness: ≤3mm

Temperature control range: 15℃~55℃

Temperature control accuracy: ±0.1℃

Humidity control range: 50%RH~90%RH;

Humidity control accuracy: ±2%RH

Carrier gas flow: 100 ml/min

Carrier gas type: 99.999% high purity nitrogen

Dimensions: 680×380×300 mm

Power supply: AC 220V 50Hz

Net weight: 72kg

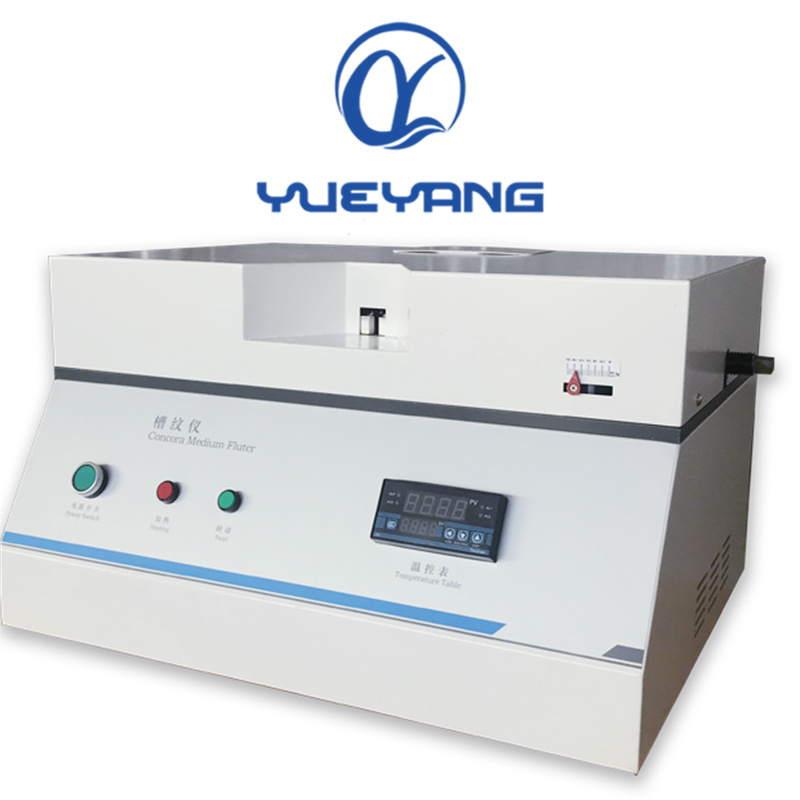

Product detail pictures:

Related Product Guide:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Quality Inspection for Transmittance: 0.1 % - YY311 Water Vapor Transmission Rate Tester (infrared method) – Yueyang , The product will supply to all over the world, such as: Cairo, Switzerland, Malta, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.