Rubber&Plastic testing Instruments

-

(China)YY707A Rubber Fatigue Cracking Tester

I.Application:

Rubber fatigue cracking tester is used to measure the cracking properties of vulcanized rubber,

rubber shoes and other materials after repeated flexure.

II.Meeting the standard:

GB/T 13934 、GB/T 13935、GB/T 3901、GB/T 4495、 ISO 132、ISO 133

-

(China)YY-BTG-02 Bottle Wall Thickness Tester

Instrument Introduction:

YY-BTG-02 bottle wall thickness tester is an ideal measuring instrument for PET beverage bottles, cans,glass bottles, aluminum cans and other packaging containers. It is suitable for precisemeasurement of wall thickness and bottle thickness of the packaging container with complexlines, with advantages of convenience, durability, high precision and low price. It is widely used in glass bottles; plastic bottles/buckets production enterprises and pharmaceutical, health products,cosmetics, beverages, cooking oil and wine production enterprises.

Meeting the standards

GB2637-1995, GB/T2639-2008, YBB00332002

-

(China)YY-PNY-10 Torque tester-10 Nm

Instruments Introductions:

YY-CRT-01 Verticality Deviation (circular runout) Tester is suitable for ampoules, mineral water

bottles, beer bottles and other round bottle packaging round run-out test. This product conforms

to national standards, simple structure, wide range of application, convenient and durable,

high precision. It is an ideal testing instrument for pharmaceutical, pharmaceutical packaging,

food, daily chemical and other enterprises and drug inspection institutions.

Meet the standard:

QB 2357-1998、YBB00332004、YBB00352003、YBB00322003、YBB00192003、

YBB00332002、YBB00052005、YBB00042005、QB/T1868

-

(China)YY-CRT-01 Verticality Deviation (circular runout) Tester

Instruments Introductions:

YY-CRT-01 Verticality Deviation (circular runout) Tester is suitable for ampoules, mineral water

bottles, beer bottles and other round bottle packaging round run-out test. This product conforms

to national standards, simple structure, wide range of application, convenient and durable,

high precision. It is an ideal testing instrument for pharmaceutical, pharmaceutical packaging,

food, daily chemical and other enterprises and drug inspection institutions.

Meet the standard:

QB 2357-1998、YBB00332004、YBB00352003、YBB00322003、YBB00192003、

YBB00332002、YBB00052005、YBB00042005、QB/T1868

-

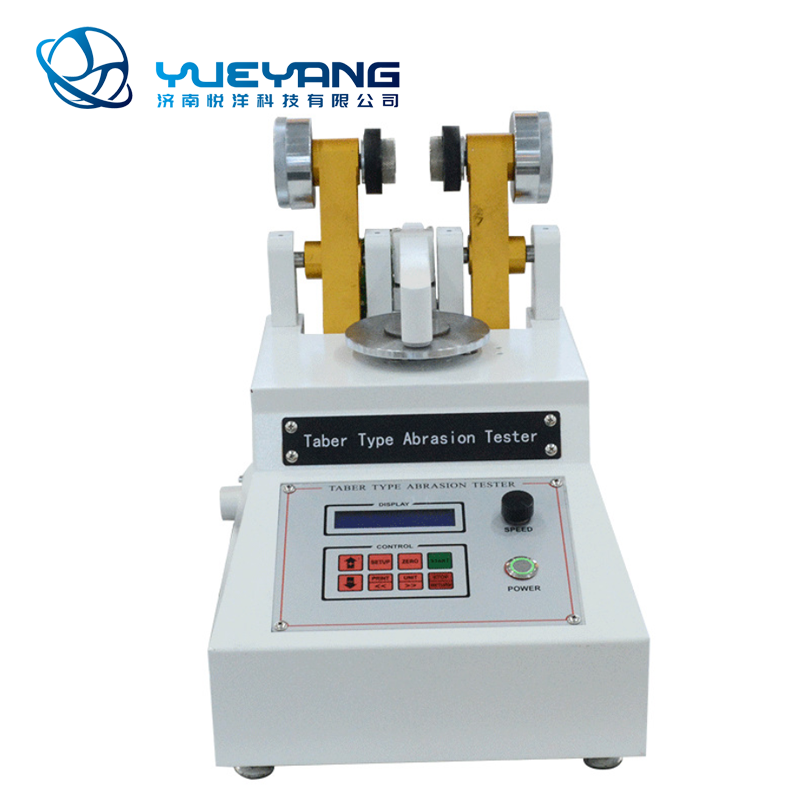

(China)YY-TABER Leather Abrasion Tester

Instruments Introduction:

This machine is suitable for cloth, paper, paint, plywood, leather, floor tile, floor, glass, metal film,

natural plastic and so on. The test method is that the rotating test material is supported by a

pair of wear wheels, and the load is specified. The wear wheel is driven when the test

material is rotating, so as to wear the test material. The wear loss weight is the weight

difference between the test material and the test material before and after the test.

Meeting the standard:

DIN-53754、53799、53109,TAPPI-T476,ASTM-D3884,ISO5470-1,GB/T5478-2008

-

(China)YYPL 200 Leather Tensile Strengh Tester

I.Applications:

Suitable for leather, plastic film, composite film, adhesive, adhesive tape, medical patch, protective

film, release paper, rubber, artificial leather, paper fiber and other products tensile strength, peeling strength, deformation rate, breaking force, peeling force, opening force and other performance tests.

II.Application field:

Tape, automotive, ceramics, composite materials, construction, food and medical equipment, metal,

paper, packaging, rubber, textiles, wood, communication and various special-shaped materials

-

(China)YYP-4 Leather Dynamic Waterproof Tester

I.Product Introduction:

Leather, artificial leather, cloth, etc., under the water on the outside, the bending action is applied

to measure the permeability resistance index of the material. Number of test pieces 1-4 Counters 4 groups, LCD, 0~ 999999,4 sets ** 90W Volume 49×45×45cm Weight 55kg Power 1 #, AC220V,

2 A.

II.Test principle:

Leather, artificial leather, cloth, etc., under the water on the outside, the bending action is applied to measure the permeability resistance index of the material.

-

(China)YYP 50L Constant Temperature&Humidity Chamber

Meeting standard:

The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 “Basic parameter Verification method of environmental test equipment for electrical and electronic products Low temperature, high temperature, constant wet heat, alternating wet heat test equipment”

Basic environmental test procedures for electrical and electronic products Test A: Low temperature

test method GB 2423.1-89 (IEC68-2-1)

Basic environmental test procedures for electrical and electronic products Test B: High temperature

test method GB 2423.2-89 (IEC68-2-2)

Basic environmental test procedures for electrical and electronic products Test Ca: Constant wet

heat test method GB/T 2423.3-93 (IEC68-2-3)

Basic environmental test procedures for electrical and electronic products Test Da: Alternating

humidity and heat test method GB/T423.4-93(IEC68-2-30)

-

(China)YYN06 Bally Leather Flexing Tester

I.Applications:

Leather flexure testing machine is used for the flexure test of shoe upper leather and thin leather

(shoe upper leather, handbag leather, bag leather, etc.) and cloth folding back and forth.

II.Test principle

The flexibility of the leather refers to the bending of one end surface of the test piece as the inside

and the other end surface as the outside, especially the two ends of the test piece are installed on

the designed test fixture, one of the fixtures is fixed, the other fixture is reciprocated to bend the

test piece, until the test piece is damaged, record the number of bending, or after a certain number

of bending. Look at the damage.

III.Meet the standard

BS-3144, JIB-K6545, QB1873, QB2288, QB2703, GB16799-2008, QB/T2706-2005 and other

leather flexure inspection method required specifications.

-

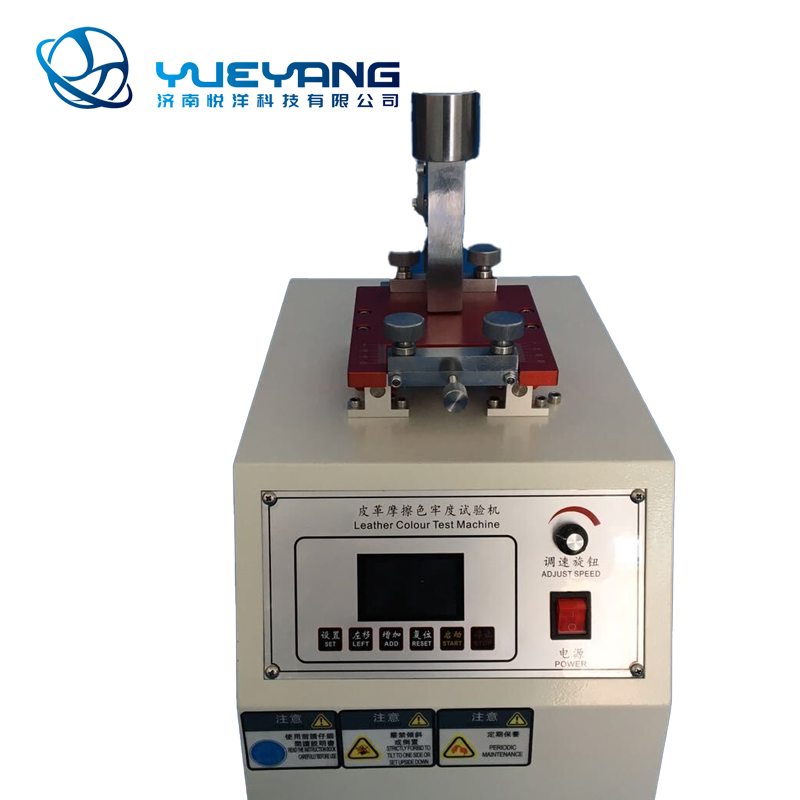

(China)YY127 Leather Color Test Machine

Summary:

Leather color test machine in the test of dyed upper, lining leather, after friction damage and

decolorization degree, can do dry, wet friction two tests, the test method is dry or wet white wool

cloth, wrapped in the surface of the friction hammer, and then the repeated friction clip on the test bench test piece, with power off memory function

Meet the standard:

The machine meet ISO / 105, ASTM/D2054, AATCC / 8, JIS/L0849 ISO – 11640, SATRA PM173, QB/T2537 standard, etc

-

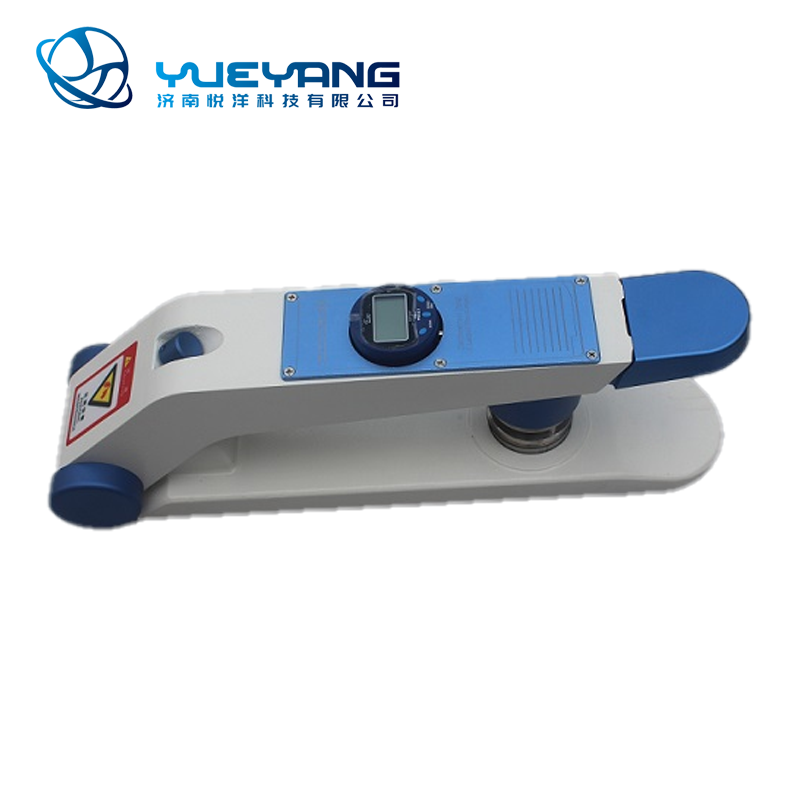

(China)YY119 Leather Softness Tester

I.Equipment features:

This instrument fully conforms to IULTCS,TUP/36 standard, accurate, beautiful, easy to operate

and maintain, portable advantages.

II.Equipment application:

This instrument is specially used to measure the leather, hides, in order to understand the same

batch or the same package of leather in the soft and hard is uniform, can also test a single piece

of leather, each part of the soft difference.

-

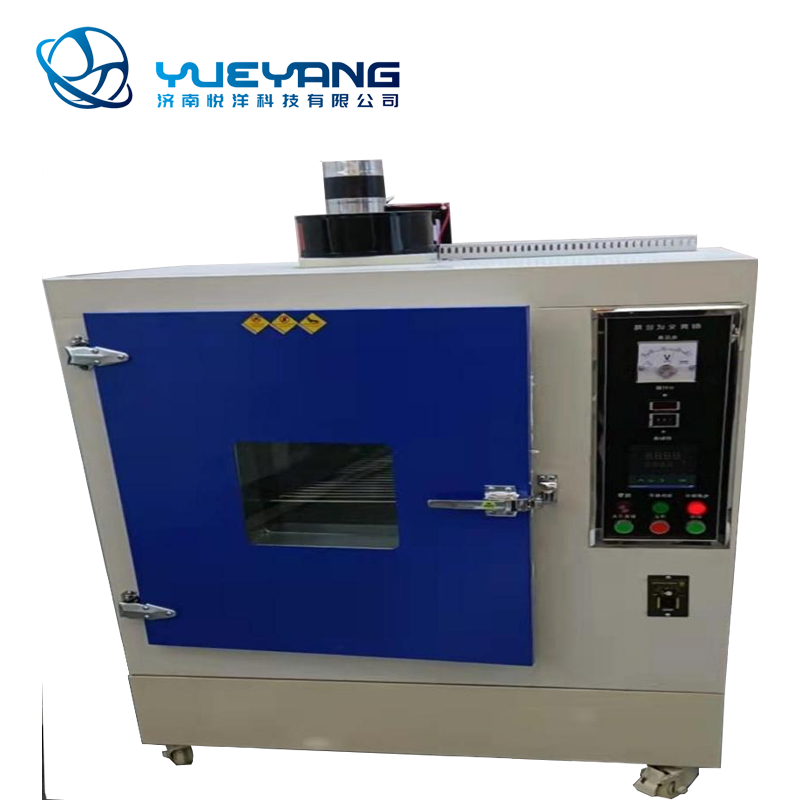

(China)YY NH225 Yellowing Resistance Aging Oven

Summary:

It is manufactured in accordance with ASTM D1148 GB/T2454HG/T 3689-2001, and its function

is to simulate the ultraviolet radiation and heat of sunlight. The sample is exposed to ultraviolet

radiation and temperature in the machine, and after a period of time, the degree of yellowing

resistance of the sample is observed. The staining gray label can be used as a reference to

determine the grade of yellowing. The product is affected by sunlight radiation during use or the

influence of the container environment during transportation, resulting in the color change of the

product.

-

(China)YYP-WDT-20A1 Electronic Universal Testing Machine

I.Summarize

WDT series micro control electronic universal testing machine for double screw, host, control, measurement, operation integrated structure. It is suitable for tensile, compression, bending, elastic modulus, shearing, stripping, tearing and other mechanical properties test of all kinds of

(thermosetting, thermoplastic) plastics, FRP, metal and other materials and products. Its software system adopts WINDOWS interface (multiple language versions to meet the use of different

countries and regions), can measure and judge various performance according to national

standards, international standards or user-provided standards, with test parameter setting storage,

test data collection, processing and analysis, display print curve, test report print-out and other functions. This series of testing machine is suitable for material analysis and inspection of engineering plastics, modified plastics, profiles, plastic pipes and other industries. Widely used in scientific research institutions, colleges and universities, quality inspection departments, production enterprises.

Product characteristics

The transmission part of this series of testing machine adopts imported brand AC servo system, deceleration system, precision ball screw, high-strength frame structure, and can be selected

according to the need of large deformation measuring device or small deformation electronic

extender to accurately measure the deformation between the effective marking of the sample. This series of testing machine integrates modern advanced technology in one, beautiful shape, high precision, wide speed range, low noise, easy operation, accuracy up to 0.5, and provides a variety

of specifications/uses of fixtures for different users to choose. This series of products has obtained

the EU CE certification.

II.Executive standard

Meet GB/T 1040, GB/T 1041, GB/T 8804, GB/T 9341, ISO 7500-1, GB 16491, GB/T 17200,

ISO 5893, ASTM D638, ASTM D695, ASTM D790 and other standards.

-

(China)YYP 20KN Electronic Universal Tension Machine

1.Features and uses:

20KN electronic universal material testing machine is a kind of material testing equipment with

domestic leading technology. The product is suitable for tensile, compression, bending, shearing, tearing, stripping and other physical properties test of metal, non-metal, composite materials and products. The measurement and control software uses Windows 10 operating system platform, graphical software interface, flexible data processing mode, modular VB programming method,

safe limit protection and other functions. It also has the function of automatic algorithm generation

and automatic editing of test report, which greatly facilitates and improves the debugging and

system redevelopment ability, and can calculate parameters such as maximum force, yield force,

non-proportional yield force, average stripping force, elastic modulus, etc. It has novel structure, advanced technology and stable performance. Simple operation, flexible, easy maintenance;

Set a high degree of automation, intelligence in one. It can be used for mechanical properties

analysis and production quality inspection of various materials in scientific research departments, colleges and universities and industrial and mining enterprises.

-

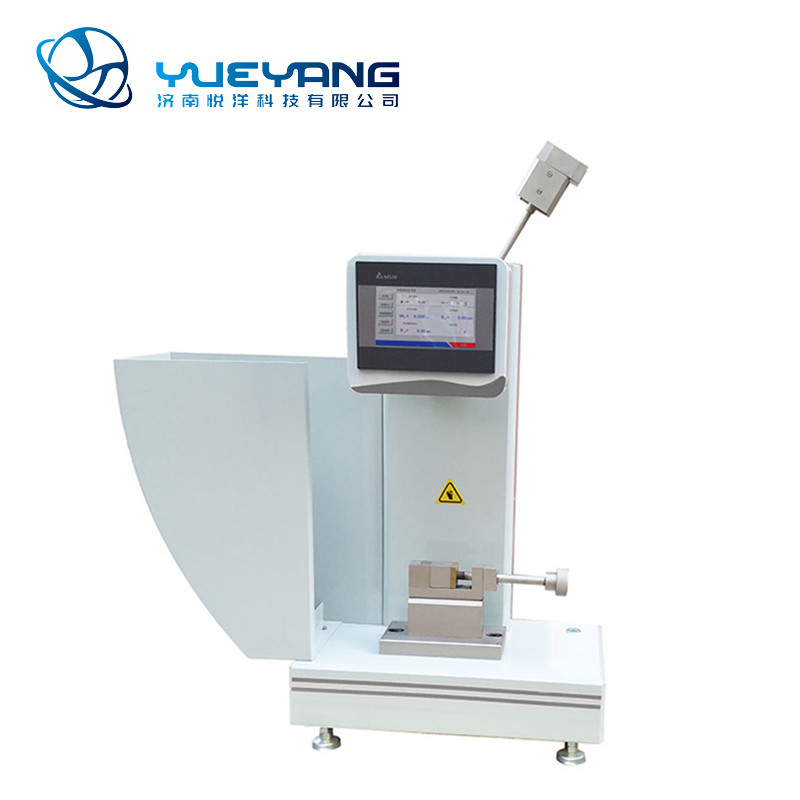

(China)YY- IZIT Izod Impact Tester

I.Standards

l ISO 180

l ASTM D 256

II.Application

Izod method is used to investigate the behavior of specified types of specimen under impact conditions defined and for estimating the brittleness or toughess of specimens within the limitations inherent in the test conditions.

The test specimen, supported as a vertical cantilever beam, is broken by a single impact of a striker, with the line of impact a fixed distance from the specimen clamp and, in the case of notched

specimens, from the centerline of the notch.

-

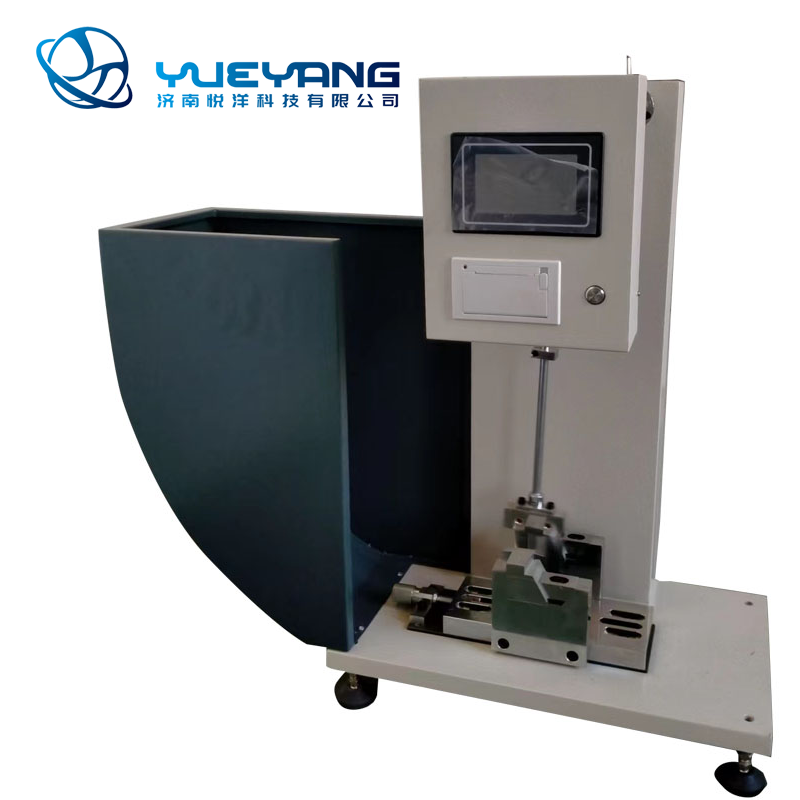

(China)YY22J Izod Charpy Tester

I.Features and uses:

The digital display cantilever beam impact testing machine is mainly used for the determination of

impact toughness of hard plastics, reinforced nylon FRP, ceramics, cast stone, electrical insulation materials and other non-metallic materials. With stable and reliable performance, high precision,

easy to use and other characteristics, can directly calculate the impact energy, save 60 historical

data, 6 kinds of unit transformation, two screen display, can display the practical Angle and Angle

peak or energy, is the chemical industry, scientific research units, colleges and universities, quality inspection departments and professional manufacturers laboratory and other units ideal test

equipment.

-

(China)YY-300F High Frequency Inspection Screening Machine

I. Application:

Used in laboratory, quality inspection room and other inspection departments for particles and

powder materials

Particle size distribution measurement, product impurity content determination analysis.

The test screening machine can realize different screening frequency and screening time according

to different materials through electronic delay device (i.e. timing function) and directional frequency modulator; At the same time, it can also achieve the same direction of the work track and the same vibration duration, frequency and amplitude for the same batch of materials, which can greatly reduce the uncertainty caused by manual screening, thereby reducing the test error, ensuring the consistency of sample analysis data, and improving product quality

Quantity makes standard judgment.

-

(China)YY-S5200 Electronic Laboratory Scale

- Overview:

Precision Electronic scale adopts gold-plated ceramic variable capacitance sensor with concise

and space efficient structure, quick response, easy maintenance, wide weighing range, high precision, extraordinary stability and multiple functions. This series is widely used in laboratory and industry of food, medicine, chemical and metalwork etc. This type of balance, excellent in stability, superior in safety and efficient in operating space, becomes a normally used type in laboratory with cost-effective.

II.Advantage:

1. Adopts gold-plated ceramic variable capacitance sensor;

2. Highly sensitive moisture sensor enable to minimize effect of moisture on operation;

3. Highly sensitive temperature sensor enable to minimize effect of temperature on operation;

4. Various weighing mode: weighing mode, check weighing mode, percent weighing mode, parts counting mode,etc;

5. Various weighing unit conversion functions: grams, carats, ounces and other units of free

switching, suitable for various requirements of the weighing work;

6. Large LCD display panel, bright and clear, provides user with easy operation and read.

7. The balances are characterized by streamline design,high strength,anti-leakage, anti-static

property and corrosion resistance. Suitable for a variety of occasions;

8. RS232 interface for bidirectional communication between balances and computers, printers,

PLCs and other external devices;

-

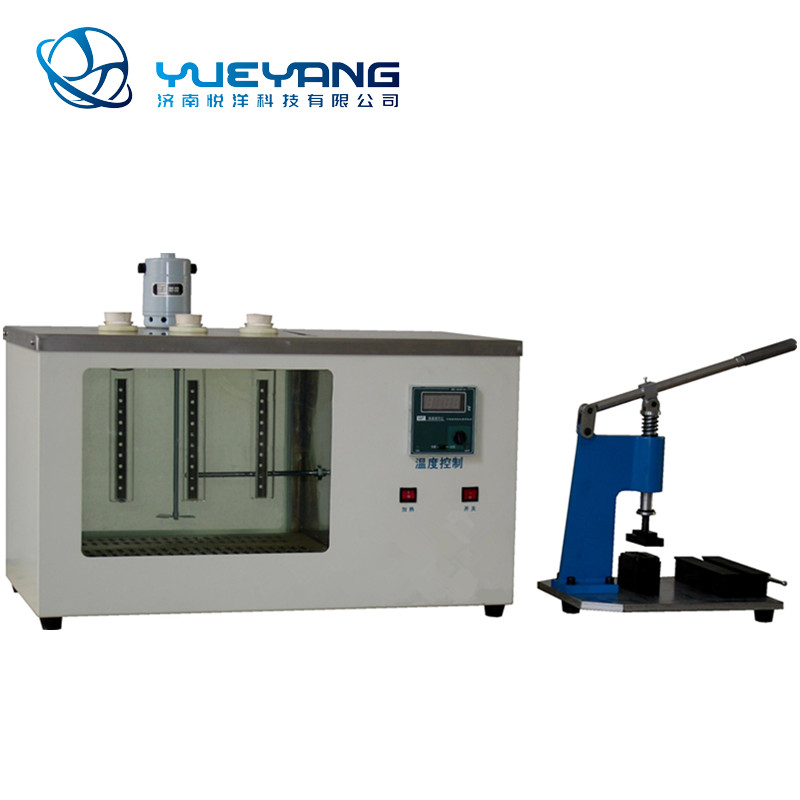

(China)YYPL Environmental Stress Cracking Resistance Tester(ESCR)

I.Applications:

The environmental stress test device is mainly used to obtain the phenomenon of cracking

and destruction of non-metallic materials such as plastics and rubber under the long-term

action of stress below its yield point. The ability of the material to resist environmental stress

damage is measured. This product is widely used in plastics, rubber and other polymer

materials production, research, testing and other industries. The thermostatic bath of this

product can be used as an independent test equipment to adjust the state or temperature of

various test samples.

II.Meeting Standard:

ISO 4599–《 Plastics -Determination of resistance to environmental stress cracking (ESC)-

Bent strip method》

GB/T1842-1999–《Test method for environmental stress-cracking of polyethylene plastics》

ASTMD 1693–《Test method for environmental stress-cracking of polyethylene plastics》

-

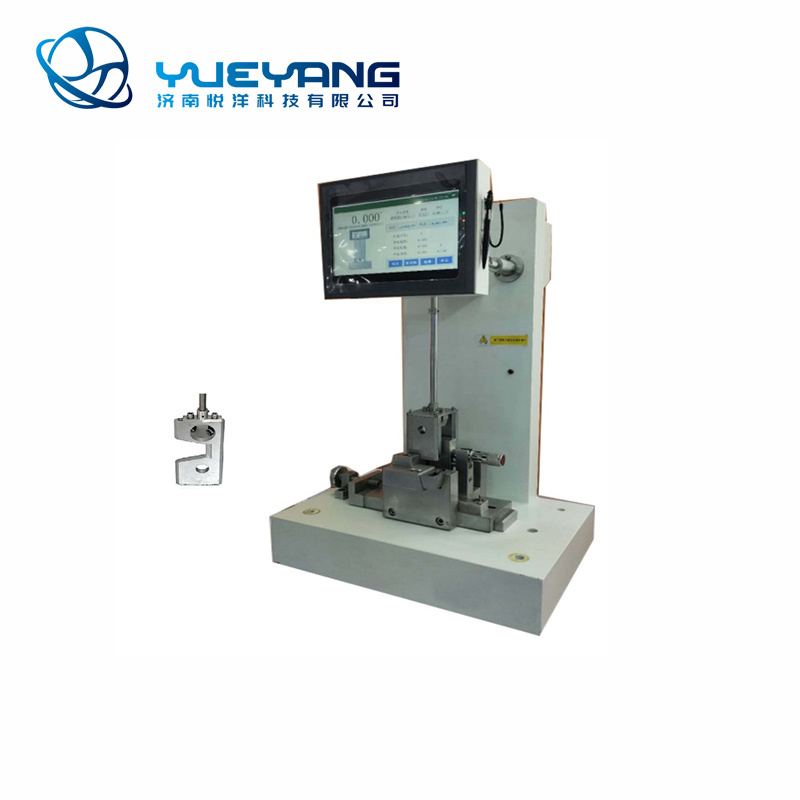

(China)YYP-JC Charpy Impact Tester

Technical standard

The product meets the requirements of test equipment for ENISO179, GB/T1043, ISO9854, GB/T18743 and DIN53453 ,ASTM D 6110 standards.