Products

-

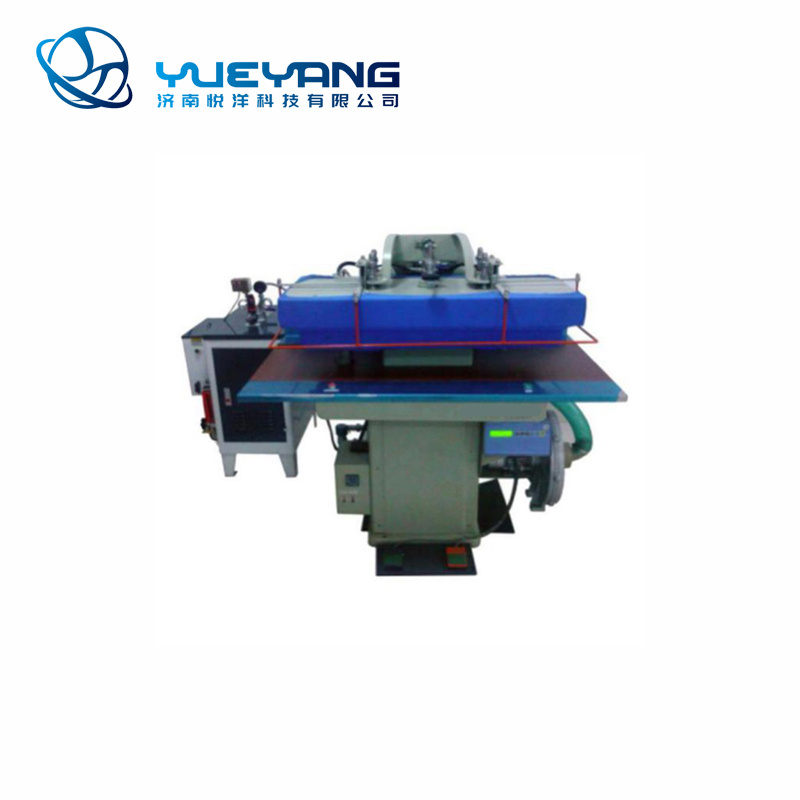

YY607Z Automatic Steam Ironing Shrinkage Tester

1. Pressure mode: pneumatic

2. Air pressure adjustment range: 0– 1.00Mpa; + / – 0.005 MPa

3. Ironing die surface size: L600×W600mm

4. Steam injection mode: upper mold injection type -

YYPL-6C Handsheet Former(RAPID-KOETHEN)

Our this hand sheet former is applicable to research and experiments in papermaking research institutes and paper mills.

It forms pulp into a sample sheet, then puts the sample sheet on the water extractor for drying and then carries out the inspection of the physical intensity of the sample sheet to appraise the performance of the raw material of pulp and beating process specifications. Its technical indicators conform to the international & China specified standard for papermaking physical inspection equipment.

This former combines vacuum-sucking & forming, pressing, vacuum-drying into one machine, and all-electric control.

-

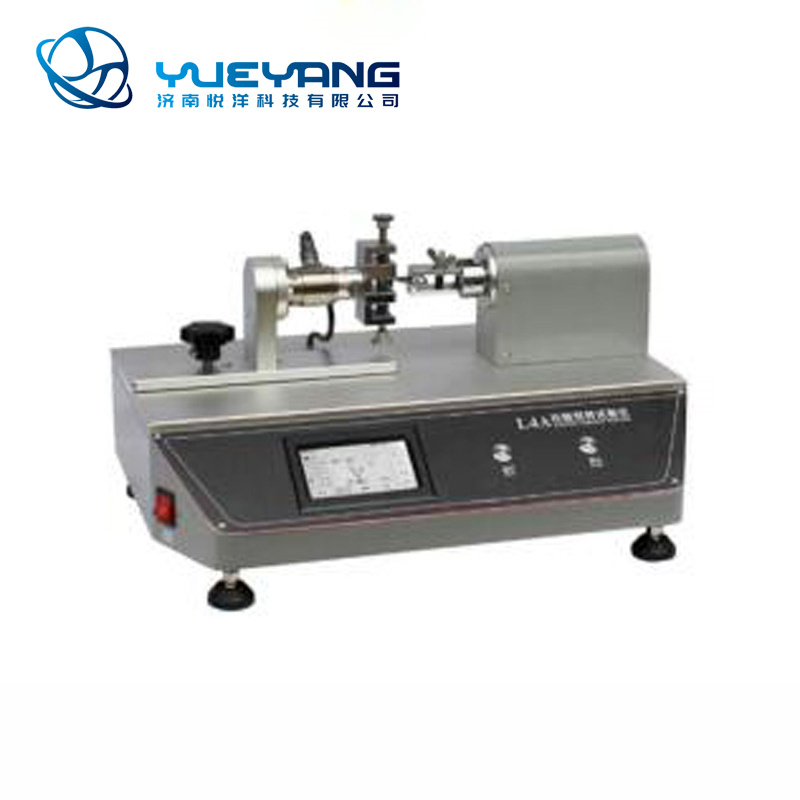

YY-L4A Zipper Torsion Tester

Used for testing the torsion resistance of pull head and pull sheet of metal, injection molding and nylon zipper.

-

YY025A Electronic Wisp Yarn Strength Tester

Used for measuring strength and elongation of various yarn strands.

-

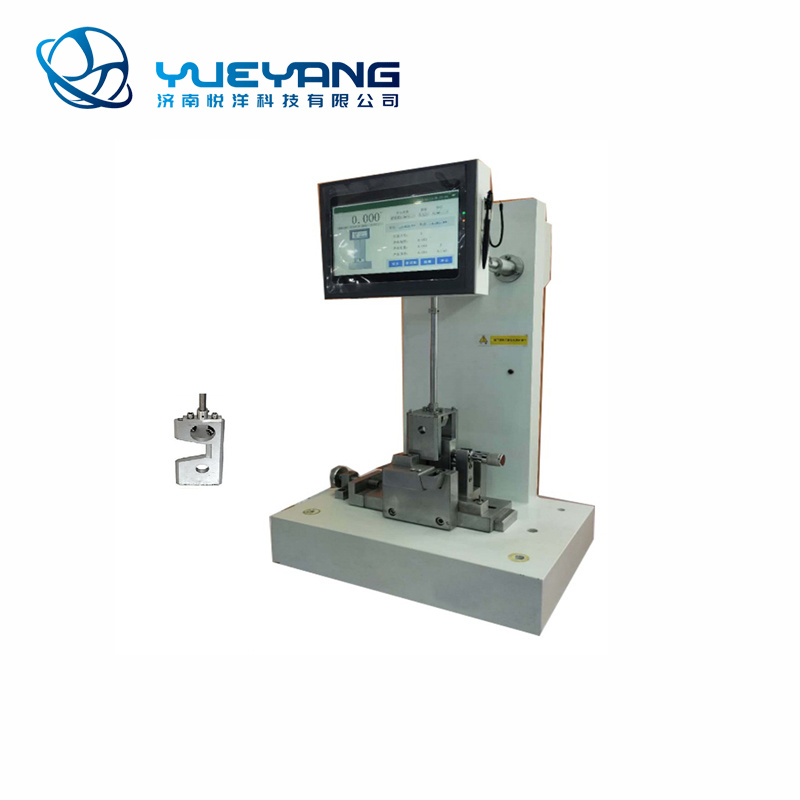

YYP-JC Simple Beam Impact Testing Machine

Technical Parameter

1. Energy Range: 1J, 2J, 4J, 5J

2. Impact velocity: 2.9m/s

3. Clamp span: 40mm 60mm 62 mm 70mm

4. Pre-poplar angle: 150 degrees

5. Shape size: 500 mm long, 350 mm wide and 780 mm high

6. Weight: 130kg (including attachment box)

7. Power supply: AC220 + 10V 50HZ

8. Working environment: in the range of 10 ~35 ~C, the relative humidity is less than 80%. There is no vibration and corrosive medium around.

Model/Function Comparison of Series Impact Testing MachinesModel Impact energy Impact velocity Display measure JC-5D Simply supported beam 1J 2J 4J 5J 2.9m/s Liquid crystal Automatic JC-50D Simply supported beam 7.5J 15J 25J 50J 3.8m/s Liquid crystal Automatic -

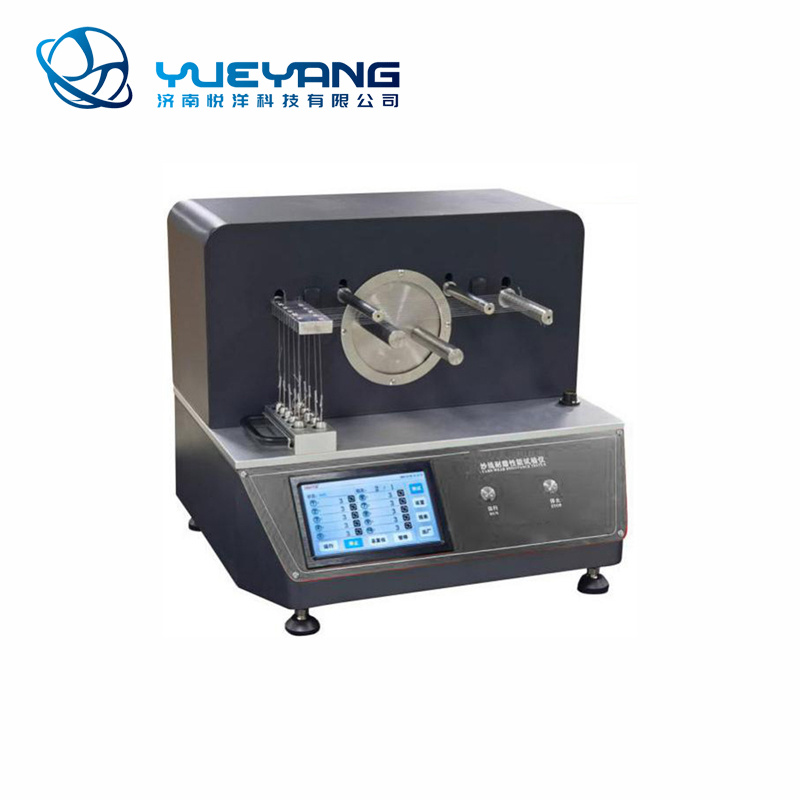

YY609A Yarn Wear Resistance Tester

The method is suitable for the determination of wear-resisting properties of pure or blended yarns made of cotton and chemical short fibers

-

YY631M Perspiration Fastness Tester

Used for testing color fastness of various textiles to acid, alkaline sweat, water, sea water, etc..

-

YY002–Button Impact Tester

Fix the button above the impact test and release a weight from a certain height to impact the button to test the impact strength.

-

YY2301 Yarn Tensiometer

It is mainly used for static and dynamic measurement of yarns and flexible wires, and can be used for rapid measurement of tension of various yarns in the process of processing. Some examples of applications are as follows: Knitting industry: Accurate adjustment of feed tension of circular looms; Wire industry: wire drawing and winding machine; Man-made fiber: Twist machine; Loading draft machine, etc.; Cotton textile: winding machine; Optical fiber industry: winding machine.

-

YY741 Shrinkage Oven

Printing and dyeing, clothing and other industries shrinkage test when hanging or flat drying equipment.

-

(China)YY378 -Dolomite Dust Clogging

The product is applicable to EN149 test standard: respiratory protective device-filtered anti-particle semi-mask; Conforming standards: BS EN149:2001+A1:2009 Respiratory protective device-filtered anti-particle semi-mask requirements test mark 8.10 blocking test, EN143 7.13 and other test standards.

Blocking test principle: the filter and mask blocking tester is used to test the amount of dust collected on the filter, the respiratory resistance of the test sample and the filter penetration (permeability) when the air flow passes through the filter by suction in a certain dust environment and reaches a certain respiratory resistance.

-

(China)YY-SW-12AC-Color fastness to washing tester

[Scope of application]

It is used for testing the colour fastness to washing, dry cleaning and shrinkage of various textiles, and also for testing the colour fastness to washing of dyes.

[Related Standards]

AATCC61/1 A / 2 A / 3 A / 4 A / 5 A, JIS L0860/0844, BS1006, GB/T3921 1/2/3/4/5, ISO105C01/02/03/04/05/06/08, etc

[Technical parameters]

1. Test cup capacity: 550ml (φ75mm×120mm) (GB, ISO, JIS and other standards)

1200ml (φ90mm×200mm) (AATCC standard)

6 PCS (AATCC) or 12 PCS (GB, ISO, JIS)

2. Distance from the center of the rotating frame to the bottom of the test cup: 45mm

3. Rotation speed

40±2)r/min

40±2)r/min4. Time control range

0 ~ 9999)min

0 ~ 9999)min5. Time control error: ≤±5s

6. Temperature control range: room temperature ~ 99.9℃;

7. Temperature control error: ≤±2℃

8. Heating method: electric heating

9. Power supply: AC380V±10% 50Hz 8kW

10. Overall size

930×690×840)mm

930×690×840)mm11. Weight: 165kg

Attachment: 12AC adopts the structure of studio + preheating room.

-

YYPL28 Vertical Standard Pulp Disintegrator

PL28-2 vertical Standard Pulp Disintegrator, Another name is standard fiber dissociation or Standard fiber blender, Pulp fiber raw material at high speed in the water, Bundle fiber dissociation of single fiber. It is used to making sheethand, measure filter degree, The preparation for pulp screening.

-

YY6000A Glove Cutting Resistance Tester

Used for testing the strength of protective gloves and uppers. Color touch screen display control, menu operation mode.

-

YY608A Yarn Slip Resistance Tester (Friction method)

The slip resistance of yarn in woven fabric was measured by friction between roller and fabric.

-

(China)YYP-JM-720A Rapid Moisture Meter

Widely used in various industries such as plastics, food, feed, tobacco, paper, food (dehydrated vegetables, meat, noodles, flour, biscuit, pie, aquatic processing), tea, beverage, grain, chemical raw materials, pharmaceutical, textile raw materials and so on, to test the free water contained in the sample

-

YY002D Fiber Fineness Analyzer

Used for measuring fiber fineness and blending content of blended fiber. The cross section shape of hollow fiber and special-shaped fiber can be observed. The longitudinal and cross-section microscopic images of the fibers are collected by the digital camera. With the intelligent assistance of the software, the longitudinal diameter data of the fibers can be tested quickly, and the functions such as fiber type labeling, statistical analysis, Excel output and electronic statements can be realized.

-

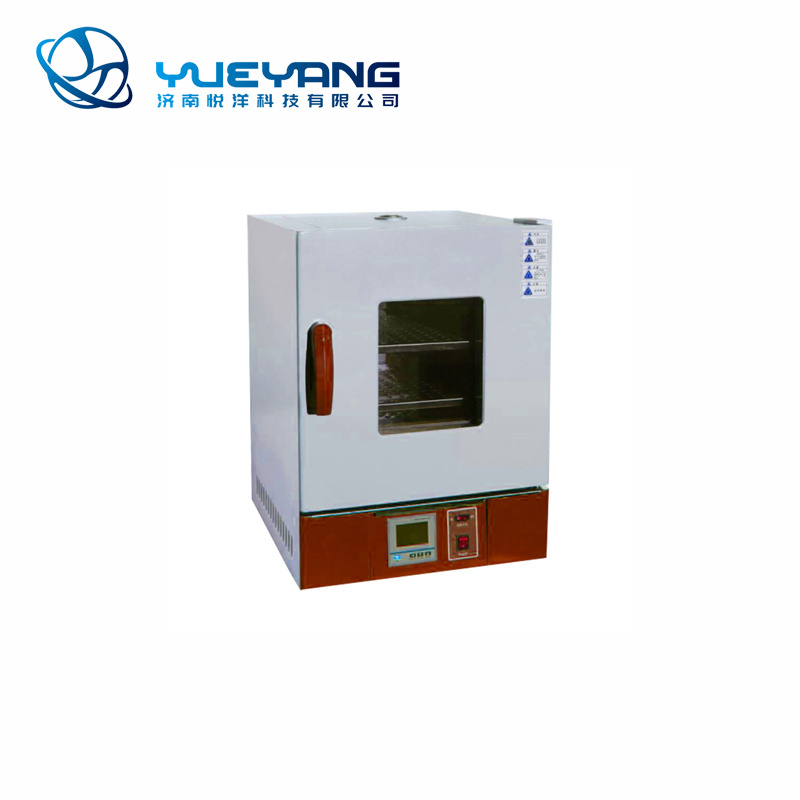

YY902A Sweat Stain Color Fastness Oven

Used for various textile materials, such as baking, drying, moisture content test and high temperature test.

-

YY003–Button Color Fastness Tester

Used for testing the color fastness and ironing resistance of buttons.

-

YY382A Automatic Eight Basket Constant Temperature Oven

Used for rapid determination of moisture content and moisture regain of cotton, wool, hemp, silk, chemical fiber and other textiles and finished products.