Textile Testing Instruments

-

YY172B Fiber Hastelloy Slicer

This instrument is used to cut the fiber or yarn into very small cross-sectional slices to observe its organizational structure.

-

(China)YY085A Fabric Shrinkage Printing Ruler

Used for printing marks during shrinkage tests.

-

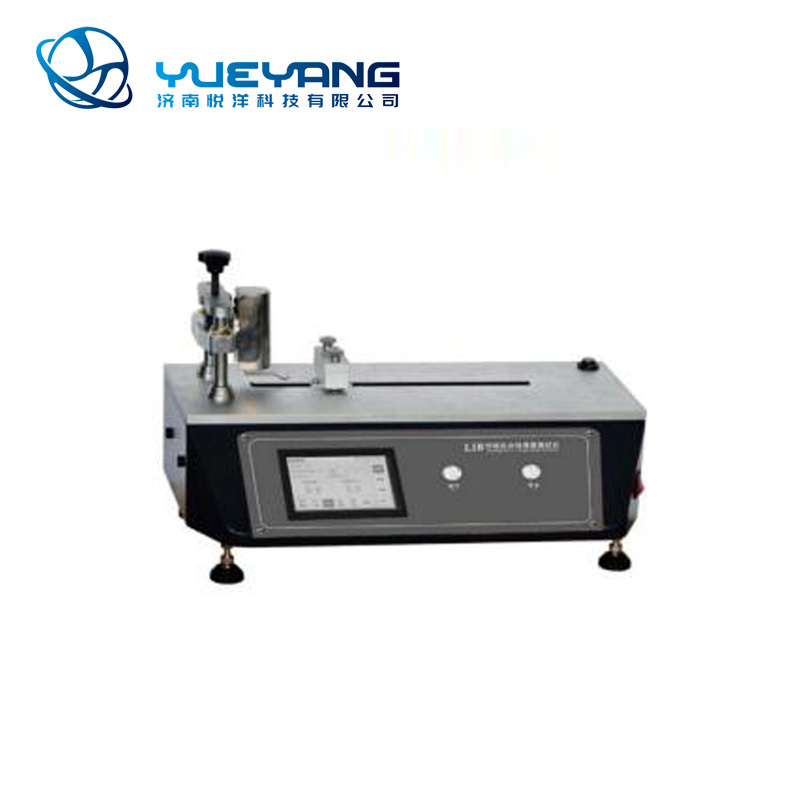

YY-L1B Zipper Pull Light Slip Tester

1. The shell of the machine adopts metal baking paint, beautiful and generous;

2.Fixture, mobile frame are made of stainless steel, never rust;

3.The panel is made of imported special aluminum material, metal keys, sensitive operation, not easy to damage;

-

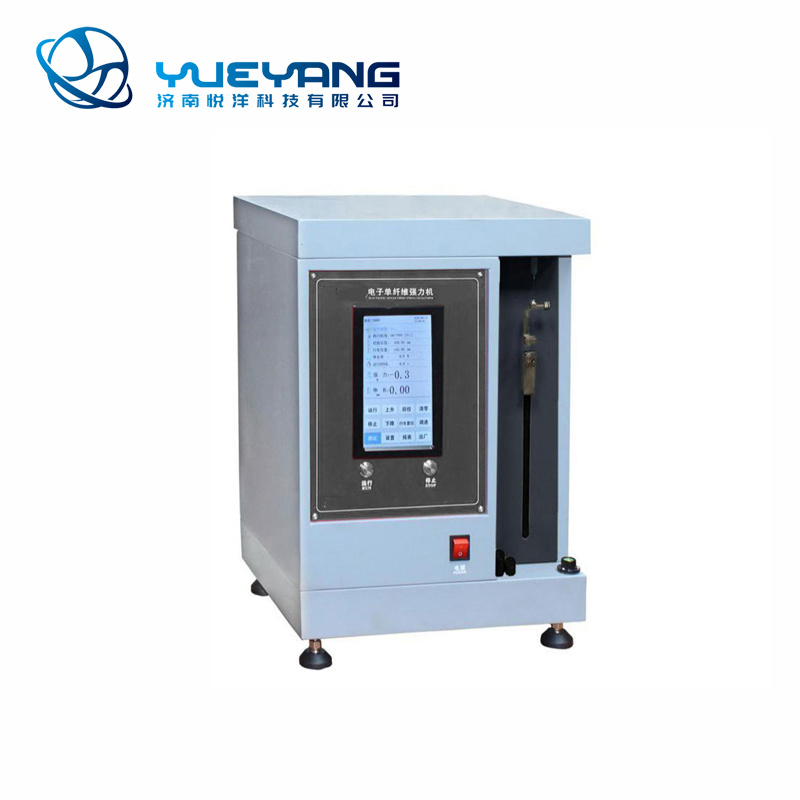

YY001Q Single Fiber Strength Tester (Pneumatic Fixture)

Used for testing the breaking strength, elongation at break, load at fixed elongation, elongation at fixed load, creep and other properties of single fiber, metal wire, hair, carbon fiber, etc.

-

YY213 Textiles Instant Contact Cooling Tester

Used for testing the coolness of pajamas, bedding, cloth and underwear, and can also measure the thermal conductivity.

-

YY611M Air-cooled Climatic Colour Fastness Tester

Used in all kinds of textile, printing and dyeing, clothing, textile, leather, plastic and other non-ferrous materials light fastness, weather fastness and light aging experiment, through control test positions inside the project such as light, temperature, humidity, get wet in the rain, provide the necessary experiment simulated natural conditions, to detect the sample light fastness, weather fastness and light aging performance.

-

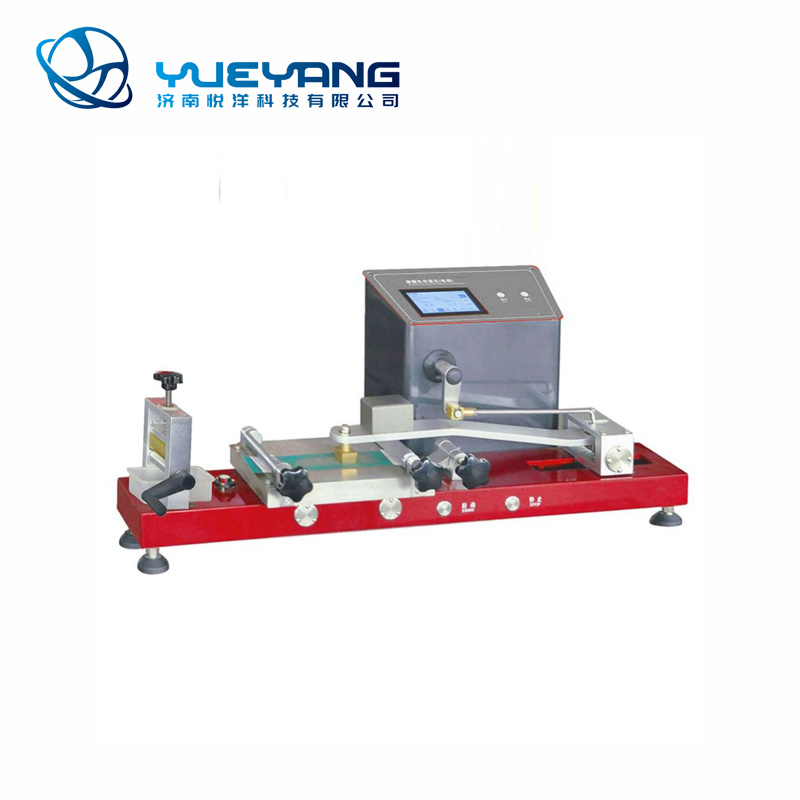

YY571F Friction Fastness Tester (Electric)

Used for friction test to evaluate color fastness in textile, knitwear, leather, electrochemical metal plate, printing and other industries.

-

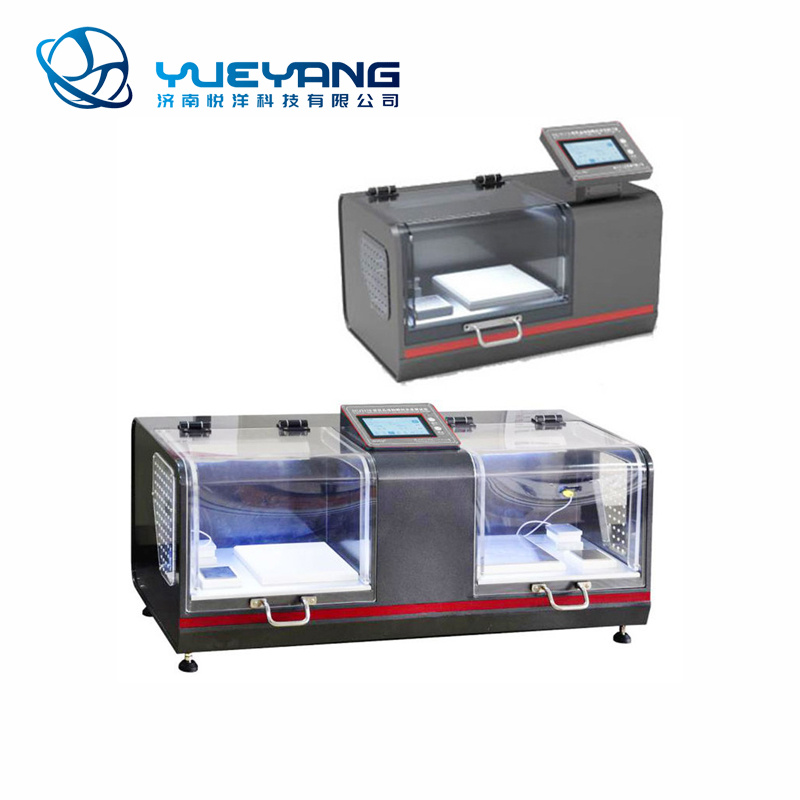

(China)YY-SW-24AC-Color fastness to washing tester

[Scope of application]

It is used for testing the colour fastness to washing, dry cleaning and shrinkage of various textiles, and also for testing the colour fastness to washing of dyes.

[Related standards]

AATCC61/1 A / 2 A / 3 A / 4 A / 5 A, JIS L0860/0844, BS1006, GB/T3921 1/2/3/4/5, ISO105C01/02/03/04/05/06/08, etc

[Technical parameters]

1. Test cup capacity: 550ml (φ75mm×120mm) (GB, ISO, JIS and other standards)

1200ml (φ90mm×200mm) (AATCC standard)

12 PCS (AATCC) or 24 PCS (GB, ISO, JIS)

2. Distance from the center of the rotating frame to the bottom of the test cup: 45mm

3. Rotation speed

40±2)r/min

40±2)r/min4. Time control range

0 ~ 9999)min

0 ~ 9999)min5. Time control error: ≤±5s

6. Temperature control range: room temperature ~ 99.9℃;

7. Temperature control error: ≤±2℃

8. Heating method: electric heating

9. Power supply: AC380V±10% 50Hz 9kW

10. Overall size

930×690×840)mm

930×690×840)mm11. Weight: 170kg

-

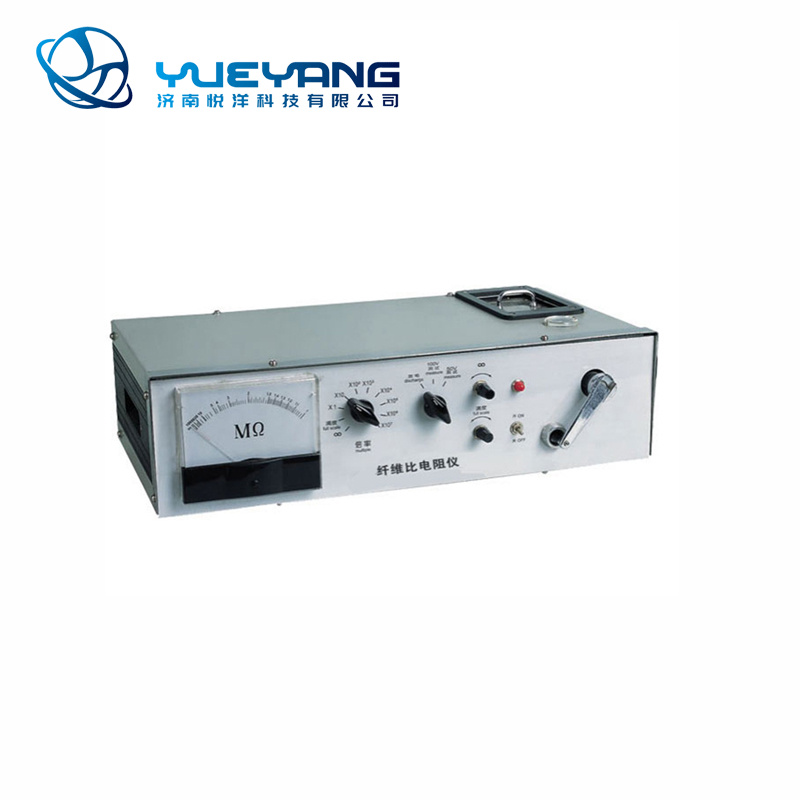

YY321 Fiber Ratio Resistance Meter

Used for measuring the specific resistance of various chemical fibers.

-

YY085B Fabric Shrinkage Printing Ruler

Used for printing marks during shrinkage tests.

-

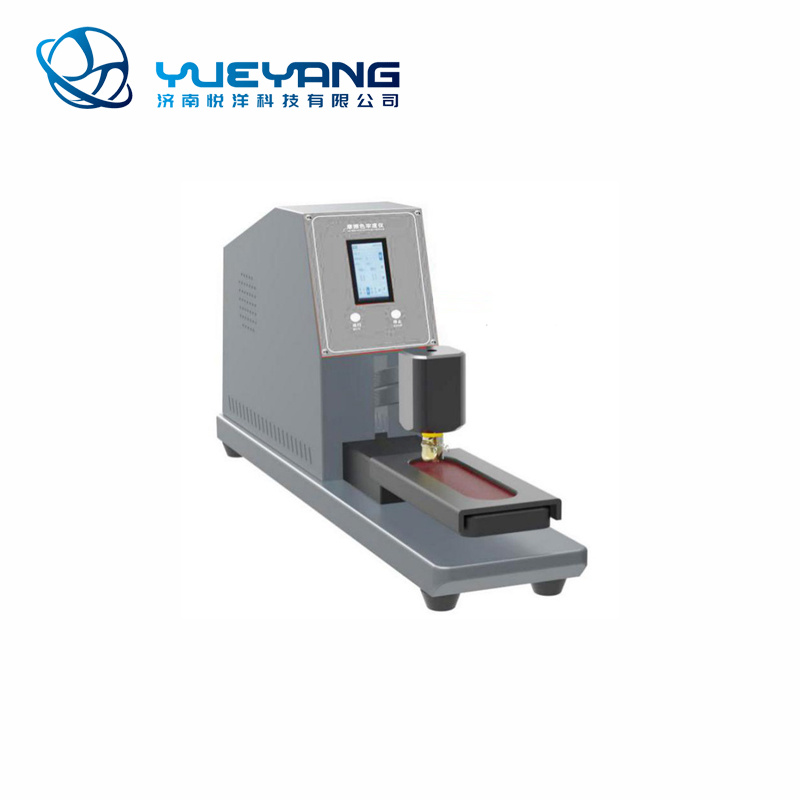

YY-L2A Zipper Load Pull Tester

1. The zipper head fixture is specially made with built-in opening structure, which is convenient for customers to use;

2. The positioning block to ensure that the lateral pull of the clamp in the initial clamping is to ensure that the lateral clamping 100°, convenient positioning of the sample;

-

YY021A Electronic Single Yarn Strength Tester

Used for testing tensile breaking strength and breaking elongation of single yarn or strand such as cotton, wool, silk, hemp, chemical fiber, cord, fishing line, cladded yarn and metal wire. This machine adopts large screen color touch screen display operation.

-

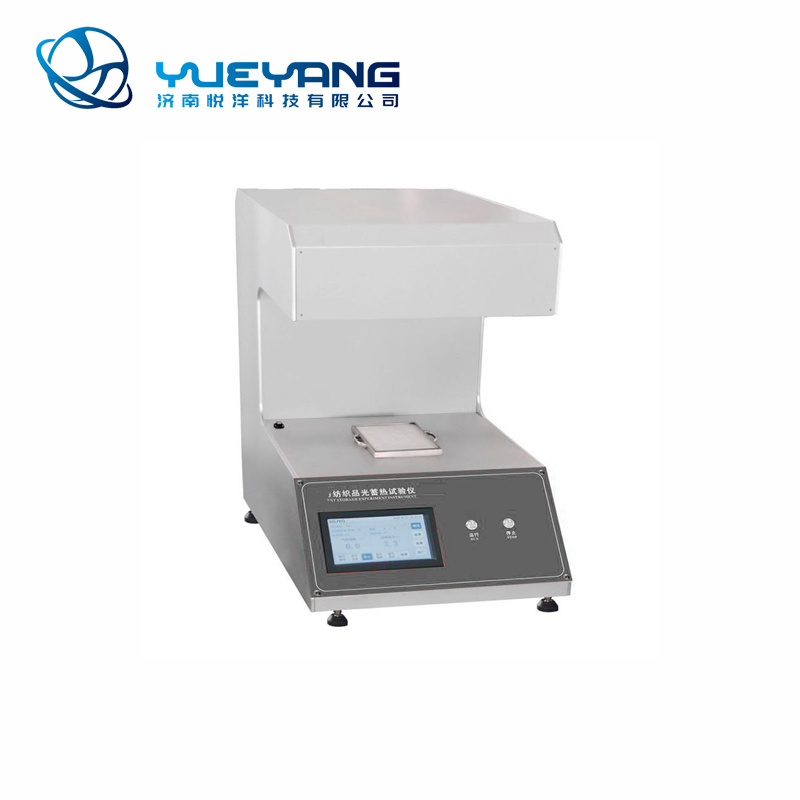

YY216A Optical Heat Storage Tester For Textiles

Used for testing the light heat storage properties of various fabrics and their products. The xenon lamp is used as the irradiation source, and the sample is placed under a certain irradiance at a specified distance. The temperature of the sample increases due to the absorption of light energy. This method is used to measure the photothermal storage properties of textiles.

-

(China)YY378 -Dolomite Dust Clogging

The product is applicable to EN149 test standard: respiratory protective device-filtered anti-particle semi-mask; Conforming standards: BS EN149:2001+A1:2009 Respiratory protective device-filtered anti-particle semi-mask requirements test mark 8.10 blocking test, EN143 7.13 and other test standards.

Blocking test principle: the filter and mask blocking tester is used to test the amount of dust collected on the filter, the respiratory resistance of the test sample and the filter penetration (permeability) when the air flow passes through the filter by suction in a certain dust environment and reaches a certain respiratory resistance.

-

YY751B Constant Temperature &humidity Test Chamber

Constant temperature and humidity test chamber is also called high low temperature constant temperature and humidity test chamber, high and low temperature test chamber, programmable can simulate all kinds of temperature and humidity environment, mainly for electronics, electrical, household appliances, automobile spare parts and materials and other products under the condition of constant heat and humidity, high temperature, low temperature and alternating hot and humid test, test the technical specifications of the products and adaptability. Can also be used for all kinds of textiles, fabric before the test of temperature and humidity balance.

-

YY571G Friction Fastness Tester (Electric)

Used for friction test to evaluate color fastness in textile, knitwear, leather, electrochemical metal plate, printing and other industries.

-

(China)YY-SW-24G-Color fastness to washing tester

[Scope of application]

It is used for testing the color fastness to washing, dry cleaning and shrinkage of all kinds of textiles, and also for testing the color fastness to washing of dyes.

[Related standards]

AATCC61/1A /2A/3A/4A/5A, JIS L0860/0844, BS1006, GB/T5711,

GB/T3921 1/2/3/4/5, ISO105C01 02/03/04/05/06/08, DIN, NF,

CIN/CGSB, AS, etc.

[Instrument characteristics]

1. 7 inch multi-functional color touch screen control, easy to operate;

2. Automatic water level control, automatic water, drainage function, and set to prevent dry burning function.

3. High-grade stainless steel drawing process, beautiful and durable;

4. With door touch safety switch and check device, effectively protect the scald, rolling injury;

5. Using imported industrial MCU program control temperature and time, configuration of “proportional integral (PID)”

Adjust function, effectively prevent temperature “overshoot” phenomenon, and make the time control error ≤±1s;

6. Solid state relay control heating tube, no mechanical contact, stable temperature, no noise, life Life is long;

7. Built-in a number of standard procedures, direct selection can be automatically run; And support program editing to save

Storage and single manual operation to adapt to different methods of standard;

- The test cup is made of imported 316L material, high temperature resistance, acid and alkali resistance, corrosion resistance.

[Technical parameters]

1. Test cup capacity: 550ml (φ75mm×120mm) (GB, ISO, JIS and other standards)

1200ml (φ90mm×200mm) [AATCC standard (selected)]

2. Distance from the center of the rotating frame to the bottom of the test cup: 45mm

3. Rotation speed

40±2)r/min

40±2)r/min4. Time control range: 9999MIN59s

5. Time control error: < ±5s

6. Temperature control range: room temperature ~ 99.9℃

7. Temperature control error: ≤±1℃

8. Heating method: electric heating

9. Heating power: 9kW

10. Water level control: automatic into, drainage

11. 7 inch multi-functional color touch screen display

12. Power supply: AC380V±10% 50Hz 9kW

13. Overall size

1000×730×1150)mm

1000×730×1150)mm14. Weight: 170kg

-

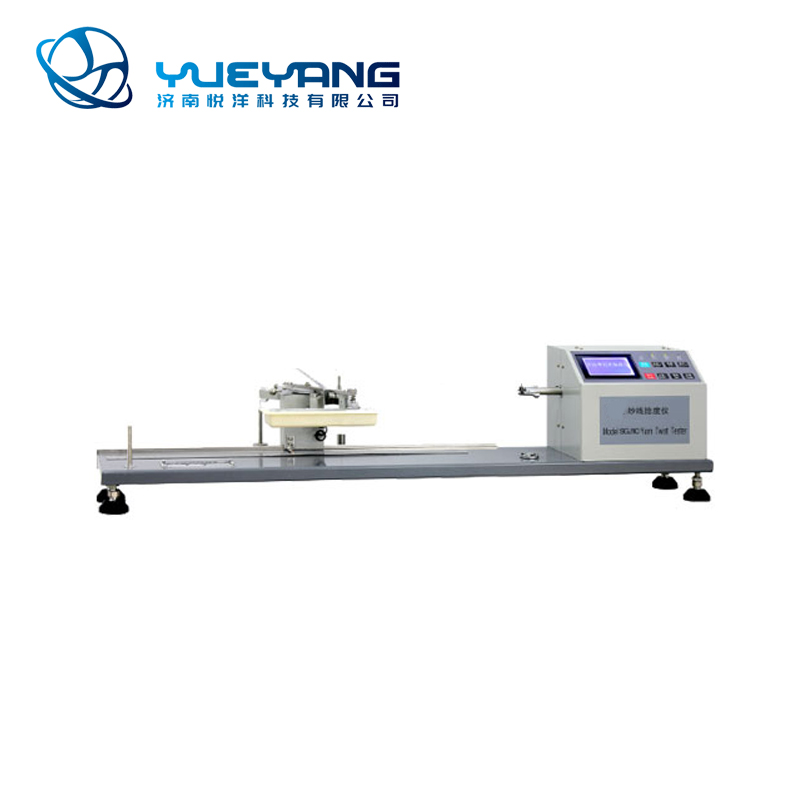

YY331C Yarn Twist Counter

Used for testing twist, twist irregularity, twist shrinkage of all kinds of cotton, wool, silk, chemical fiber, roving and yarn.

-

YY089A Fabric Shrinkage Tester Automatic

Used for measurement of shrinkage and relaxation of all kinds of cotton, wool, hemp, silk, chemical fiber fabrics, clothing or other textiles after washing.

-

YY-L2B Zipper Load Pull Tester

Used for life test of metal, injection molding and nylon zipper under specified load and pull times