Textile Testing Instruments

-

YY815A-II Fabric Flame Retardant Tester (Vertical method)

Used for flame retardant testing of interior materials of aircraft, ships and automobiles, as well as outdoor tents and protective fabrics. CFR 1615 CA TB117 CPAI 84 1. Adopt rotor flowmeter to adjust flame height, convenient and stable; 2.Color touch screen display control, Chinese and English interface, menu operation mode; 3. Adopt motor and reducer imported from Korea, the igniter moves stably and accurately; 4. The burner adopts high quality high precision Bunsen burner, the flame intens... -

YY815A Fabric Flame Retardant Tester (vertical method)

Used for the determination of flame retardant properties of medical protective clothing, curtain, coating products, laminated products, such as flame retardant, smoldering and carbonization tendency. GB 19082-2009 GB/T 5455-1997 GB/T 5455-2014 GB/T 13488 GB/T 13489-2008 ISO 16603 ISO 10993-10 1. Display and control: large screen color touch screen display and operation, Chinese and English interface, metal keys parallel control. 2. Vertical combustion test chamber material: imported 1.5mm bru... -

YY548A Heart-shaped Bending Tester

The principle of the instrument is to clamp the two ends of the strip specimen after reverse superposition on the test rack, the specimen is heart-shaped hanging, measuring the height of the heart-shaped ring, in order to measure the bending performance of the test. GBT 18318.2 ;GB/T 6529; ISO 139 1. Dimensions: 280mm×160mm×420mm (L×W×H) 2. The width of the holding surface is 20mm 3. Weight: 10kg -

YY547B Fabric Resistance &Recovery Instrument

Under standard atmospheric conditions, a predetermined pressure is applied to the sample with a standard crinkling device and maintained for a specified time. Then the wet samples were lowered under standard atmospheric conditions again, and the samples were compared with the three-dimensional reference samples to evaluate the appearance of the samples. AATCC128–wrinkle recover of fabrics 1. Color touch screen display, Chinese and English interface, menu type operation. 2. The instrumen... -

YY547A Fabric Resistance &Recovery Instrument

Appearance method was used to measure the crease recovery property of fabric. GB/T 29257; ISO 9867-2009 1. Color touch screen display, Chinese and English interface, menu type operation. 2. The instrument is equipped with a windshield, can wind and can play a dustproof role. 1. Pressure range: 1N ~ 90N 2.Speed: 200±10mm/min 3. Time range: 1 ~ 99min 4. Diameter of upper and lower indentors: 89±0.5mm 5. Stroke: 110±1mm 6. Rotation Angle: 180 degrees 7. Dimensions: 400mm×550mm×700mm (L×W×H) 8. W... -

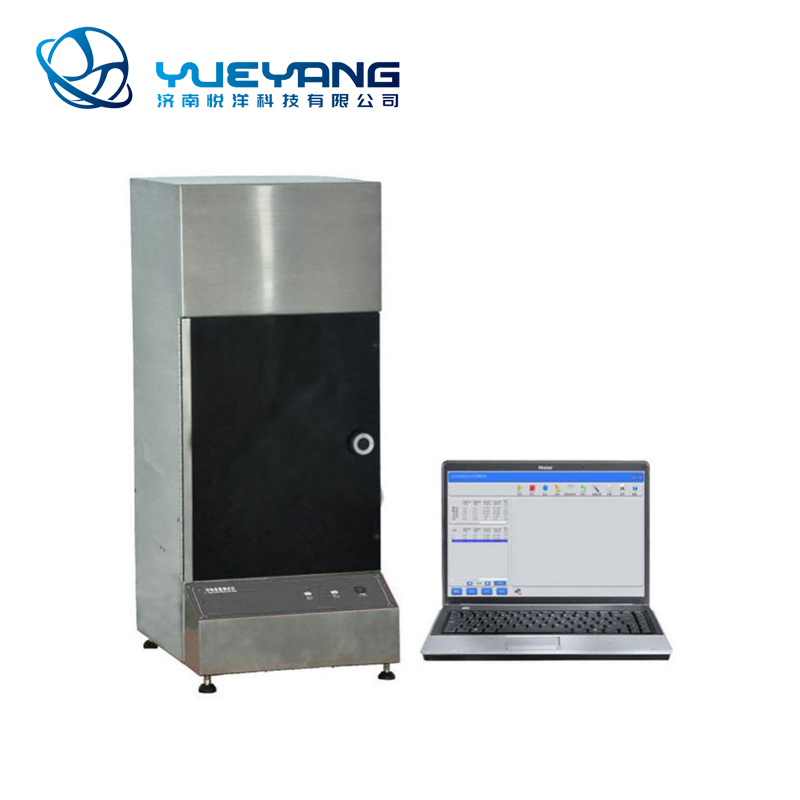

YY545A Fabric Drape Tester (Including PC)

Used for testing the drape properties of various fabrics, such as drape coefficient and ripple number of fabric surface. FZ/T 01045、GB/T23329 1. All stainless steel shell. 2. Static and dynamic drape properties of various fabrics can be measured; Including the hanging weight drop coefficient, lively rate, surface ripple number and aesthetic coefficient. 3. Image acquisition: Panasonic high resolution CCD image acquisition system, panoramic shooting, can be on the sample real scene and projec... -

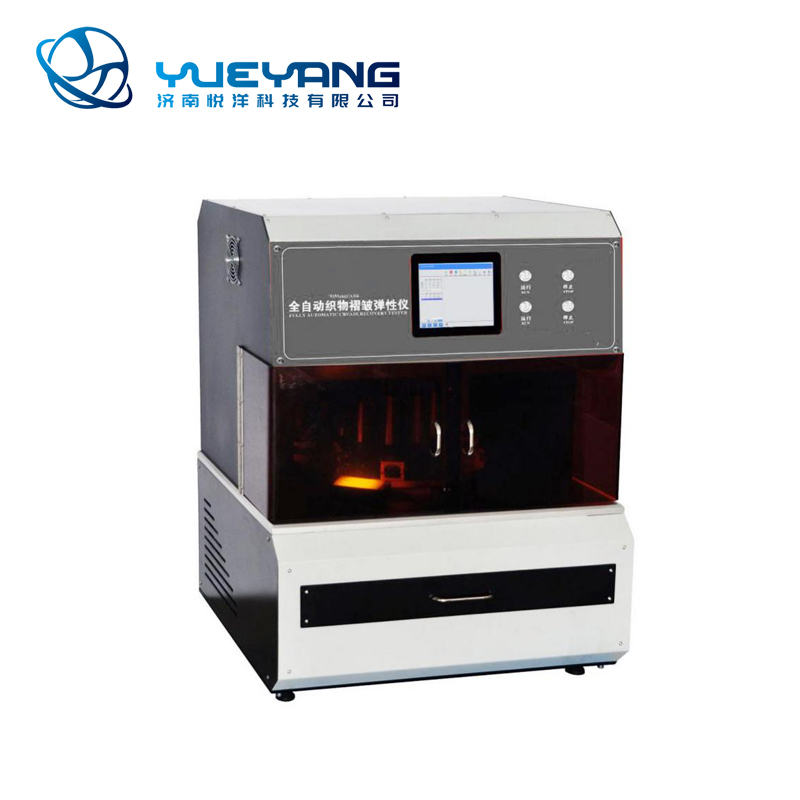

YY541F Automatic Fabric Fold Elastometer

Used for testing the recovery ability of textiles after folding and pressing. The crease recovery Angle is used to indicate the fabric recovery. GB/T3819、ISO 2313. 1. Imported industrial high resolution camera, color touch screen display operation, clear interface, easy to operate; 2. Automatic panoramic shooting and measurement, realize the recovery Angle: 5 ~ 175° full range automatic monitoring and measurement, can be analyzed and processed on the sample; 3. The release of weight hammer i... -

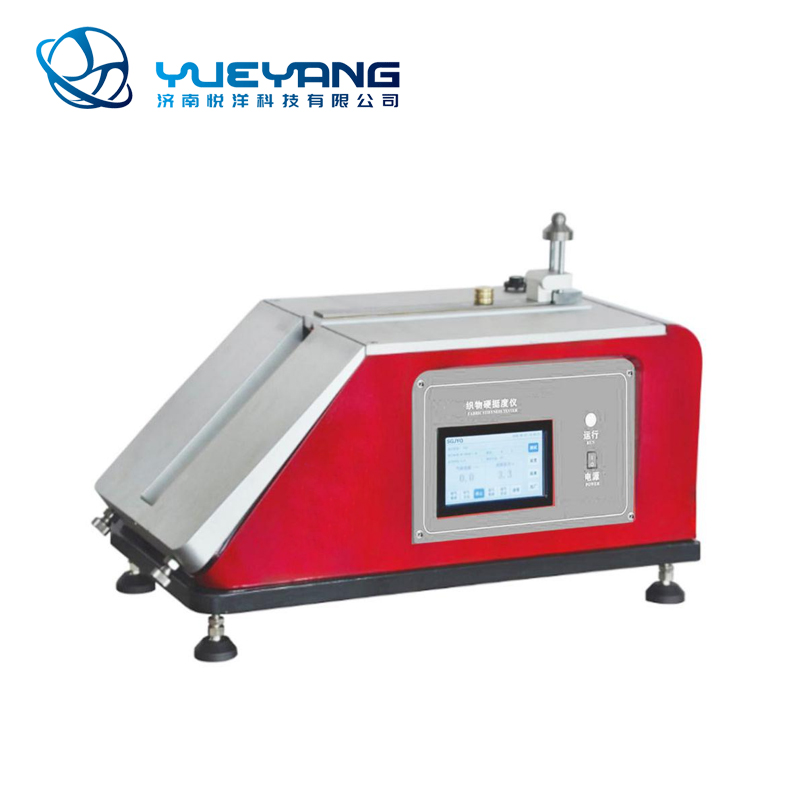

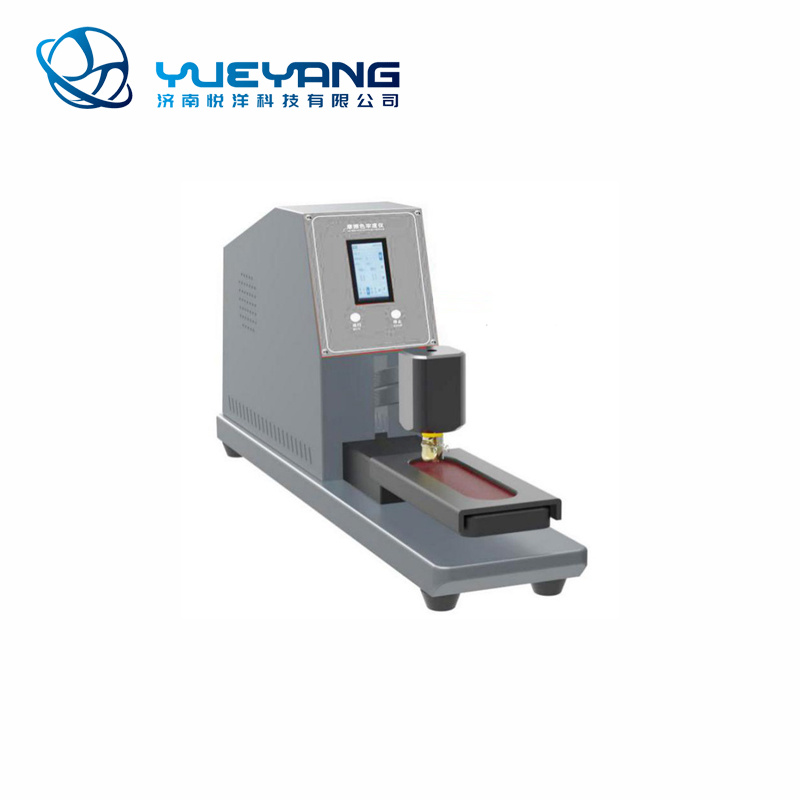

YY207B Fabric Stiffness Tester

It is used for testing the stiffness of cotton, wool, silk, hemp, chemical fiber and other kinds of woven fabrics, knitted fabrics, nonwoven fabrics and coated fabrics. It is also suitable for testing the stiffness of flexible materials such as paper, leather, film and so on. GBT18318.1-2009、ISO9073-7-1995、ASTM D1388-1996. 1.The sample can be tested Angle: 41°, 43.5°, 45°, convenient Angle positioning, meet the requirements of different testing standards; 2.Adopt infrared measurement method... -

-

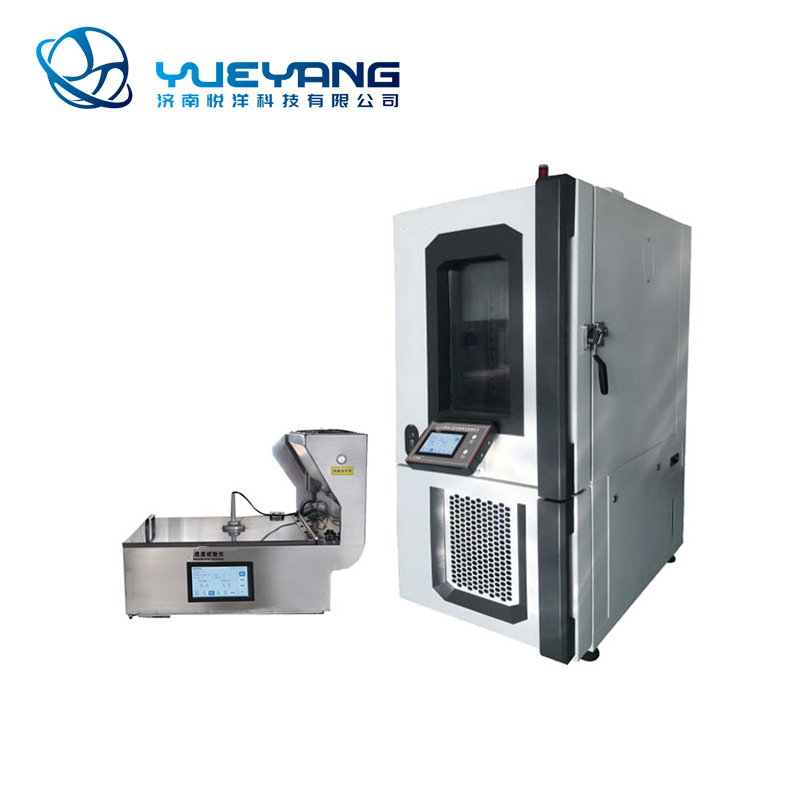

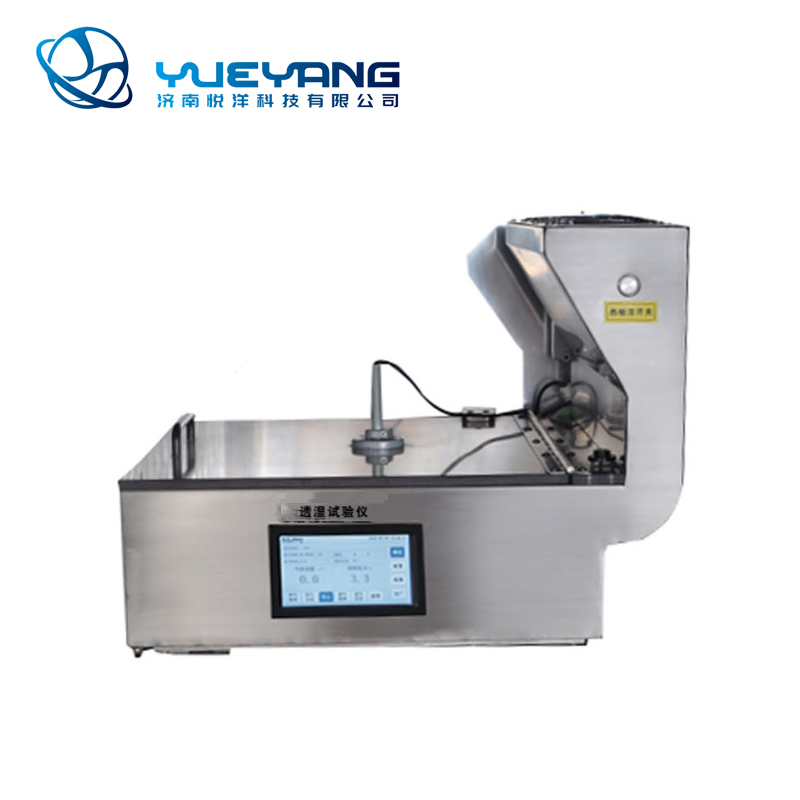

YY 501B Moisture Permeability Tester (Including constant temperature &chamber)

Used for measuring moisture permeability of medical protective clothing, all kinds of coated fabric, composite fabric, composite film and other materials. GB 19082-2009 GB/T 12704.1-2009 GB/T 12704.2-2009 ASTM E96 ASTM-D 1518 ADTM-F1868 1. Display and control: South Korea Sanyuan TM300 large screen touch screen display and control 2.Temperature range and accuracy: 0 ~ 130℃±1℃ 3. Humidity range and accuracy: 20%RH ~ 98%RH≤±2%RH 4. Circulating airflow speed: 0.02m/s ~ 1.00m/s frequency conversi... -

YY501A-II Moisture permeability tester –(excluding constant temperature &chamber)

Used for measuring moisture permeability of medical protective clothing, all kinds of coated fabric, composite fabric, composite film and other materials. JIS L1099-2012,B-1&B-2 1.Support test cloth cylinder: inner diameter 80mm; The height is 50mm and the thickness is about 3mm. Material: Synthetic resin 2. The number of supporting test cloth canisters: 4 3. Moisture-permeable cup: 4 (inner diameter 56mm; 75 mm) 4. Constant temperature tank temperature: 23 degrees. 5. Power supply volta... -

YY 501A Moisture Permeability Tester (excluding constant temperature &chamber)

Used for measuring moisture permeability of medical protective clothing, all kinds of coated fabric, composite fabric, composite film and other materials. GB 19082-2009 ; GB/T 12704-1991 ; GB/T 12704.1-2009 ; GB/T 12704.2-2009 ASTM E96 1. Display and control: large screen touch screen display and control 2. Circulating airflow speed: 0.02m/s ~ 3.00m/s frequency conversion drive, stepless adjustable 3. Number of moisture-permeable cups: 16 4. Rotating sample rack: 0 ~ 10rpm/min(frequency co... -

(China)YY461E Automatic Air Permeability Tester

Meeting Standard:

GB/T5453、GB/T13764,ISO 9237、EN ISO 7231、AFNOR G07,ASTM D737,BS5636,DIN 53887,EDANA 140.1,JIS L1096,TAPPIT251.

-

YY 461D Textile Air Permeability Tester

sed to measure the air permeability of woven fabrics, knitted fabrics, nonwovens, coated fabrics, industrial filter materials and other breathable leather, plastic, industrial paper and other chemical products. Compliant with GB/T5453, GB/T13764, ISO 9237, EN ISO 7231, AFNOR G07, ASTM D737, BS5636, DIN 53887, EDANA 140.1, JIS L1096, TAPPIT251, ISO 9073-15 and other standards.

-

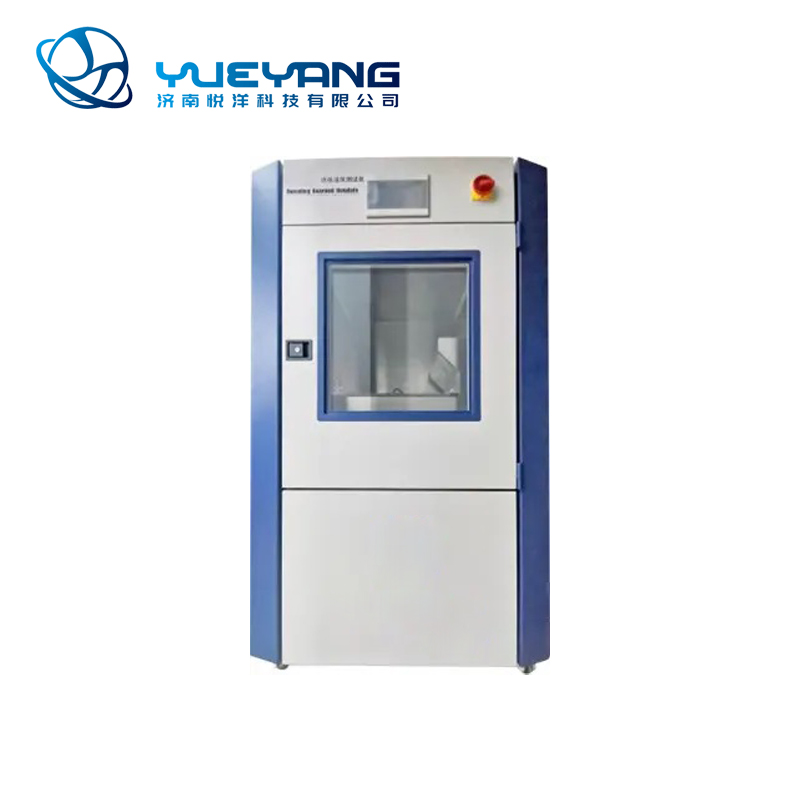

YYT255 Sweating Guarded Hotplate

YYT255 Sweating Guarded Hotplate is suitable for different kinds of textile fabrics, including industrial fabrics, non-woven fabrics and various other flat materials.

This is an instrument used to measure the thermal resistance (Rct) and moisture resistance (Ret) of textiles (and other) flat materials. This instrument is used to meet the ISO 11092, ASTM F 1868 and GB/T11048-2008 standards.

-

YY751B Constant Temperature &humidity Test Chamber

Constant temperature and humidity test chamber is also called high low temperature constant temperature and humidity test chamber, high and low temperature test chamber, programmable can simulate all kinds of temperature and humidity environment, mainly for electronics, electrical, household appliances, automobile spare parts and materials and other products under the condition of constant heat and humidity, high temperature, low temperature and alternating hot and humid test, test the technical specifications of the products and adaptability. Can also be used for all kinds of textiles, fabric before the test of temperature and humidity balance.

-

YY571G Friction Fastness Tester (Electric)

Used for friction test to evaluate color fastness in textile, knitwear, leather, electrochemical metal plate, printing and other industries.

-

(China)YY-SW-24G-Color fastness to washing tester

[Scope of application]

It is used for testing the color fastness to washing, dry cleaning and shrinkage of all kinds of textiles, and also for testing the color fastness to washing of dyes.

[Related standards]

AATCC61/1A /2A/3A/4A/5A, JIS L0860/0844, BS1006, GB/T5711,

GB/T3921 1/2/3/4/5, ISO105C01 02/03/04/05/06/08, DIN, NF,

CIN/CGSB, AS, etc.

[Instrument characteristics]

1. 7 inch multi-functional color touch screen control, easy to operate;

2. Automatic water level control, automatic water, drainage function, and set to prevent dry burning function.

3. High-grade stainless steel drawing process, beautiful and durable;

4. With door touch safety switch and check device, effectively protect the scald, rolling injury;

5. Using imported industrial MCU program control temperature and time, configuration of “proportional integral (PID)”

Adjust function, effectively prevent temperature “overshoot” phenomenon, and make the time control error ≤±1s;

6. Solid state relay control heating tube, no mechanical contact, stable temperature, no noise, life Life is long;

7. Built-in a number of standard procedures, direct selection can be automatically run; And support program editing to save

Storage and single manual operation to adapt to different methods of standard;

- The test cup is made of imported 316L material, high temperature resistance, acid and alkali resistance, corrosion resistance.

[Technical parameters]

1. Test cup capacity: 550ml (φ75mm×120mm) (GB, ISO, JIS and other standards)

1200ml (φ90mm×200mm) [AATCC standard (selected)]

2. Distance from the center of the rotating frame to the bottom of the test cup: 45mm

3. Rotation speed

40±2)r/min

40±2)r/min4. Time control range: 9999MIN59s

5. Time control error: < ±5s

6. Temperature control range: room temperature ~ 99.9℃

7. Temperature control error: ≤±1℃

8. Heating method: electric heating

9. Heating power: 9kW

10. Water level control: automatic into, drainage

11. 7 inch multi-functional color touch screen display

12. Power supply: AC380V±10% 50Hz 9kW

13. Overall size

1000×730×1150)mm

1000×730×1150)mm14. Weight: 170kg

-

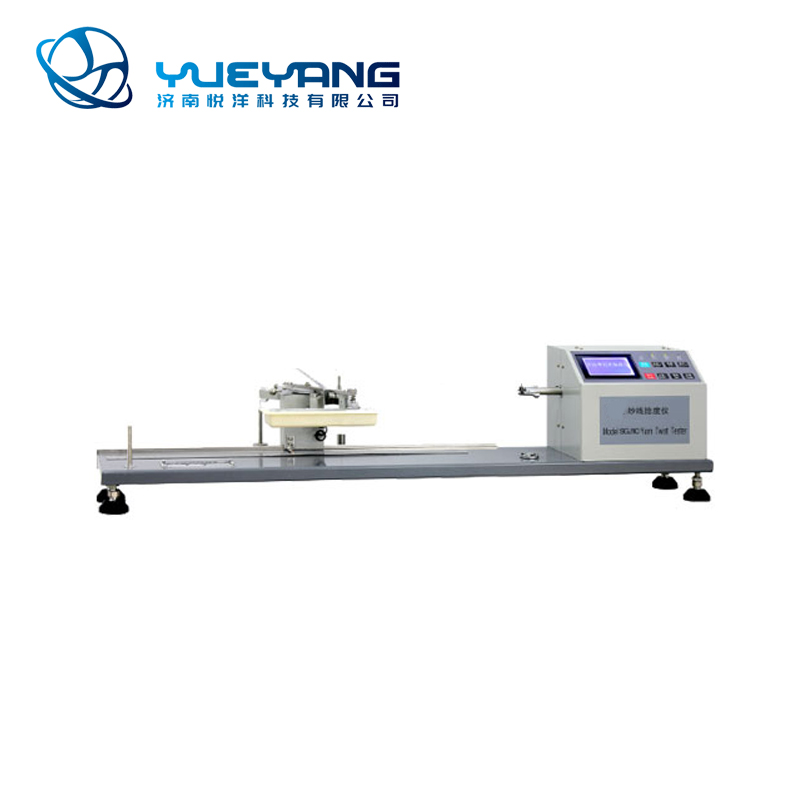

YY331C Yarn Twist Counter

Used for testing twist, twist irregularity, twist shrinkage of all kinds of cotton, wool, silk, chemical fiber, roving and yarn.

-

YY089A Fabric Shrinkage Tester Automatic

Used for measurement of shrinkage and relaxation of all kinds of cotton, wool, hemp, silk, chemical fiber fabrics, clothing or other textiles after washing.