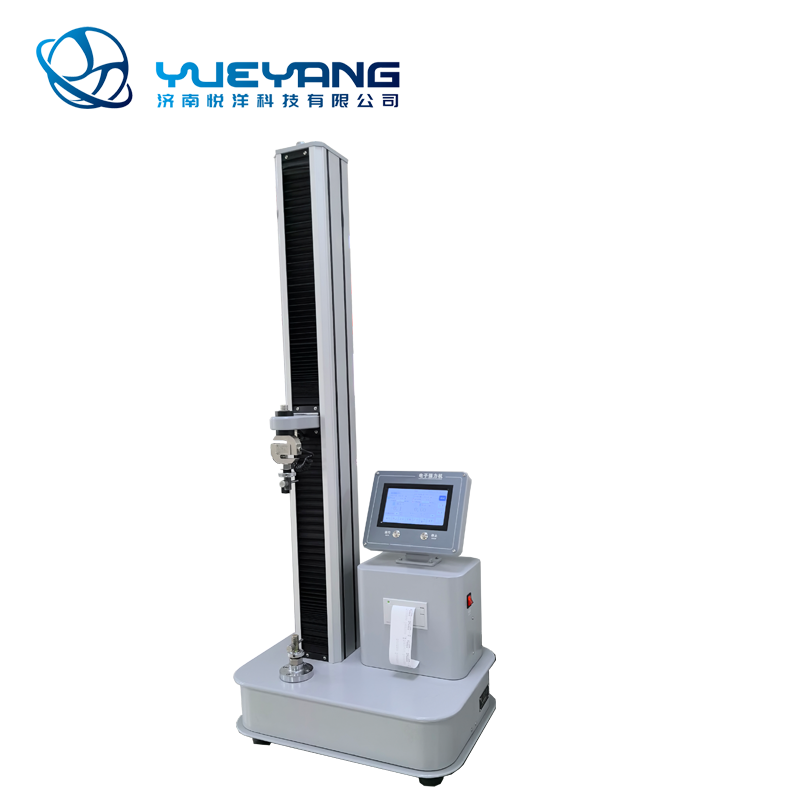

(China)YY026A Fabric Tensile Strength Tester

Used in yarn, fabric, printing and dyeing, fabric, clothing, zipper, leather, nonwoven, geotextile and other industries of breaking, tearing, breaking, peeling, seam, elasticity, creep test.

GB/T、FZ/T、ISO、ASTM.

1. Color touch screen display and control, metal keys in parallel control.

2. Imported servo driver and motor (vector control), motor response time is short, no speed overrush, speed uneven phenomenon.

3. Ball screw, precision guide rail, long service life, low noise, low vibration.

4. Korean ternary encoder for accurate control of instrument positioning and elongation.

5. Equipped with high precision sensor, "STMicroelectronics" ST series 32-bit MCU, 24 A/D converter.

6. Configuration manual or pneumatic fixture (clips can be replaced) optional, and can be customized root customer materials.

7. The whole machine circuit standard modular design, convenient instrument maintenance and upgrade.

1. Range and indexing value: 1000N (100KG), 0.1N or 5000N (500KG), 0.1N;

2.The resolution of force value 1/60000

3. Force sensor accuracy: ≤±0.05%F·S

4. The machine load accuracy: full range of 2% ~ 100% any point accuracy ≤±0.1%, grade: 1 level

5. Speed range :(0.1 ~ 500) mm/min (within the range of free setting)

6. Effective stroke: 600mm

7. Displacement resolution: 0.01mm

8.The minimum clamping distance: 10mm

9. Unit conversion: N, CN, IB, IN

10.Data storage (host part) :≥2000 groups

11. Power supply: 220V,50HZ,600W

12. Ssize: 540mm×420mm×1500mm (L×W×H)

13. Weight: about 80kg