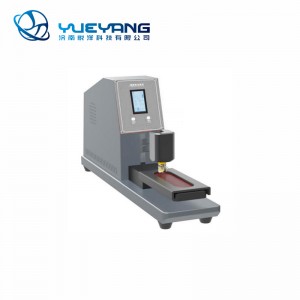

(China)YY522A Taber Abrasion Testing Machine

Used for wear resistance test of cloth, paper, coating, plywood, leather, floor tile, glass, natural rubber, etc. The principle is: with a rotating sample with a pair of wear wheel, and the specified load, the sample rotation drive wear wheel, so as to wear the sample.

FZ/T01128-2014,ASTM D3884-2001、ASTM D1044-08、FZT01044、QB/T2726.

1. Smooth operation reasonable low noise, no jump and vibration phenomenon.

2. Color touch screen display control, Chinese and English interface, menu operation mode.

3. The core control components are composed of multifunctional motherboard by 32-bit single-chip microcomputer of Italy and France.

1. Working plate diameter: Φ115mm

2. Sample thickness :0 ~ 10mm

3. Suction nozzle from the sample wear surface height :1.5mm (adjustable)

4. Working plate speed: 0 ~ 93r/min (adjustable)

5. Counting range: 0 ~ 999999 times

6. Pressure pressure: pressure sleeve weight 250g, (auxiliary device) weight 1:125g; Weight: 2:250g; Weight 3:50g;

Weight 4:750 g; Weight: 5:10 00g

7. Grinding wheel model: CS-10

8. Grinding wheel size: Φ50mm, inner hole 16mm, thickness 12mm

9. The distance between the inner edge of friction wheel and the axis of rotating platform: 26mm

10. Dimensions :1090mm×260mm×340(L×W×H)

11. Weight: 56KG

12. Power supply: AC220V, 50HZ, 80W

1.Host----1 Set

2.Weight---1 Set

3.Abrasive wheel----1 Set