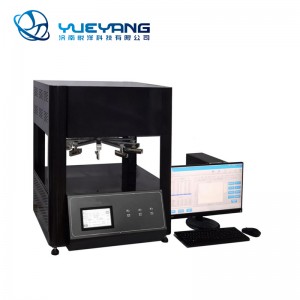

YYP-645B UV Resistant Climate Chamber

Uv resistant climate chamber use fluorescent uv lamp as light source and carry out accelerated weathering test on the material by simulating natural sun's ultraviolet radiation and condensation,in order to obtain the result of the material weatherability.

Uv resistant climate chamber can simulate the environmental conditions ,such as natural climate of uv, high humidity and condensation ,high temperature and the darkness.It merge these conditions into a loop and have it complete cycles automatically by reproducing these conditions.This is how the uv aging test chamber works.

| 2.1 Outline dimension | mm(D×W×H)580×1280×1350 |

| 2.2 Chamber dimension | mm (D×W×H)450×1170×500 |

| 2.3 Temperature range | RT+10℃~70℃ Optional setting |

| 2.4 Blackboard temperature | 63℃±3℃ |

| 2.5 Temperature fluctuation | ≤±0.5℃(No load, constant state) |

| 2.6 Temperature uniformity | ≤±2℃(No load, constant state) |

| 2.7 Time setting range | 0-9999 Minutes can be adjusted continuously. |

| 2.8 Distance between lamps | 70mm |

| 2.9 Lamp power | 40W |

| 2.10 Ultraviolet wavelengths | 315nm~400nm |

| 2.11 Support template | 75×300(mm) |

| 2.12 Template quantity | About 28 pieces |

| 2.13 Time setting range | 0~9999 hours |

| 2.14 Range of irradiance | 0.5-2.0w/㎡(Brake dimmer irradiation intensity display.) |

| 2.15 Installation power | 220V±10%,50Hz±1 Ground wire, protect the grounding resistance less than 4 Ω, about 4.5 KW |

| 3.1 Case material: A3 steel plate spraying; |

| 3.2 Interior material: SUS304 stainless steel plate of high quality. |

| 3.3 Box cover material: A3 steel plate spraying; |

| 3.4 On both sides of the chamber, 8 American q-lab (UVB-340)UV series UV lamp tubes are installed. |

| 3.5 The lid of the case is a double flip, open and closed easily. |

| 3.6 The sample frame consists of a liner and an elongated spring, all made of aluminum alloy material. |

| 3.7 The bottom part of the test case adopts the fixed PU activity wheel of high quality. |

| 3.8 The surface of the sample is 50mm and parallel to the uv light. |

| 4.1 Adopt U - type titanium alloy high-speed heating tube. |

| 4.2 Completely independent system, do not affect test and control circuit. |

| 4.3 The output power of temperature control is calculated by microcomputer, with high precision and high efficiency. |

| 4.4 It has the anti - temperature function of heating system. |

| 5.1 The black aluminum plate is used to connect the temperature sensor. |

| 5.2 Use chalkboard temperature instrument to control heating, make the temperature more stable. |

| 6.1 TEMI-990 Controller |

| 6.2 Machine interface 7 "color display/Chinese touch screen programmable controller; temperature can be read directly; usage is more convenient;control of temperature and humidity is more accurate. |

| 6.3 The choice of operation mode is: program or fixed value with free conversion. |

| 6.4 Control the temperature in the laboratory. PT100 high precision sensor is used for temperature measurement. |

| 6.5 The controller has a variety of protection functions, such as alarm of overtemperature , which can ensure that once the equipment is abnormal, it will cut off the power supply of the main parts , and send out alarm signal at the same time, the panel fault indicator light will show the fault parts to help troubleshoot quickly. |

| 6.6 The controller can fully display the program curve setting; trend map data can also save the history run curve when the program runs. |

| 6.7 The controller can be operated in a fixed value state, which can be programmed to run and built in. |

| 6.8 Programmable segment number 100STEP, program group. |

| 6.9 Switch machine: manual or make appointment time switch machine, the program runs with a power failure recovery function.(power failure recovery mode can be set) |

| 6.10 The controller can communicate with the computer through dedicated communication software. With standard rs-232 or rs-485 computer communication interface, optional with computer connection. |

| 6.11 Input voltage: AC/DC 85~265V |

| 6.12 Control output: PID(DC12V type) |

| 6.13 Analog output :4~20mA |

| 6.14 Auxiliary input: 8 switch signal |

| 6.15 Relay output :ON/OFF |

| 6.16 Light and condensation, spray and independent control can also be controlled alternately. |

| 6.17 Independent control time and alternating cycle control time of light and condensation can be set in a thousand hours. |

| 6.18 In operation or setting, if an error occurs, a warning message is provided. |

| 6.19 "Schneider" components. |

| 6.20 Non-lipper ballast and starter (ensure that the uv lamp can be turned on every time you turn on) |

Write your message here and send it to us