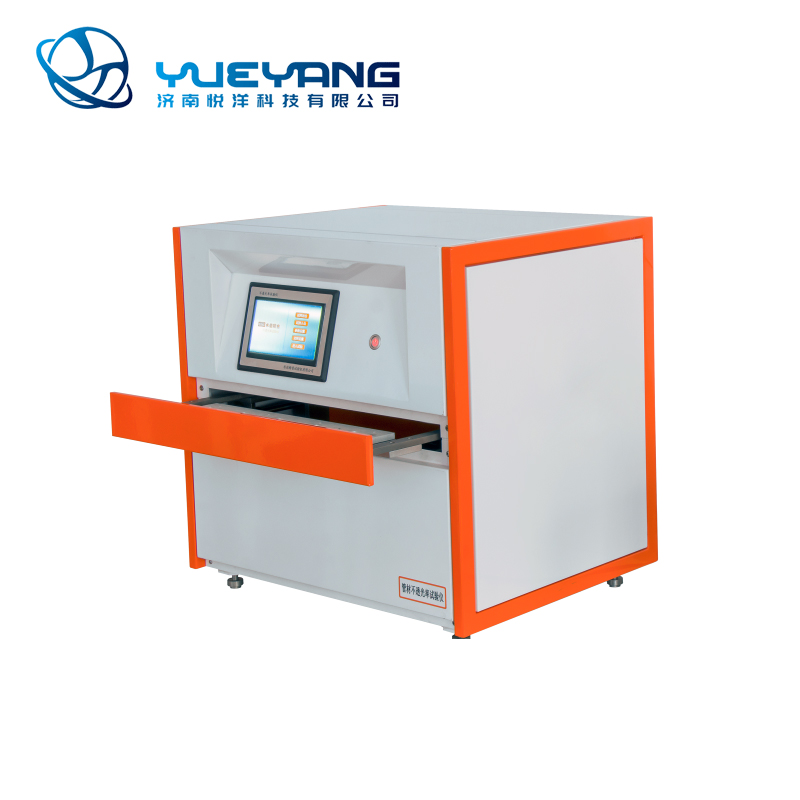

YYP-BTG-A Plastic Pipe Light Transmittance Tester

BTG-A tube light transmittance tester can be used to determine the light transmittance of plastic pipes and pipe fittings (the result is shown as A percentage). The instrument is controlled by industrial tablet computer and operated by touch screen. It has the functions of automatic analysis, recording, storage and display. This series of products are widely used in scientific research institutions, colleges and universities, quality inspection departments, production enterprises.

GB/T 21300-2007《Plastics pipes and fittings - Determination of lightfastness》

ISO7686:2005,IDT《Plastics pipes and fittings - Determination of lightfastness》

1. 5 tests can be placed, and four samples can be tested at the same time;

2. Adopt the most advanced industrial tablet computer control mode, the operation process is fully automatic;

3. The luminous flux acquisition system adopts high-precision optical collector and at least 24 bits analog-to-digital conversion circuit.

4. It has the function of automatic identification, positioning, tracking and moving testing of four samples and 12 measuring points at the same time.

5. With automatic analysis, recording, storage, display functions.

6. The instrument has the advantages of reasonable structure, stable performance, high efficiency, energy saving, simple operation and convenient maintenance.

1. Control mode: industrial tablet computer control, the test process is fully automatic, touch screen operation and display.

2. Pipe diameter range: Φ16 ~ 40mm

3. Luminous flux acquisition system: the use of high-precision optical collector and 24 bit analog-to-digital conversion circuit

4. light wavelength: 545nm±5nm, using LED energy-saving standard light source

5. luminous flux resolution: ±0.01%

6. luminous flux measurement error: ±0.05%

7.Grating: 5, specifications: 16, 20, 25, 32, 40

8. The use of grating automatic replacement system, according to the sample specifications of automatic control grating movement, automatic positioning, automatic sample tracking function.

9. Automatic entry/exit speed: 165mm/min

10. Automatic entry/exit warehouse movement distance: 200mm + 1mm

11. Sample tracking system movement speed: 90mm/min

12. Sample tracking system positioning accuracy: + 0.1mm

13. Sample rack: 5, specifications are 16, 20, 25, 32, 40.

14. The sample rack has the function of automatic positioning of the sample, to ensure that the sample surface and the incident light are vertical.

15. It has the function of automatic identification, positioning, tracking and moving test for 4 samples of the same pipe sample (3 measuring points for each sample) at one time.