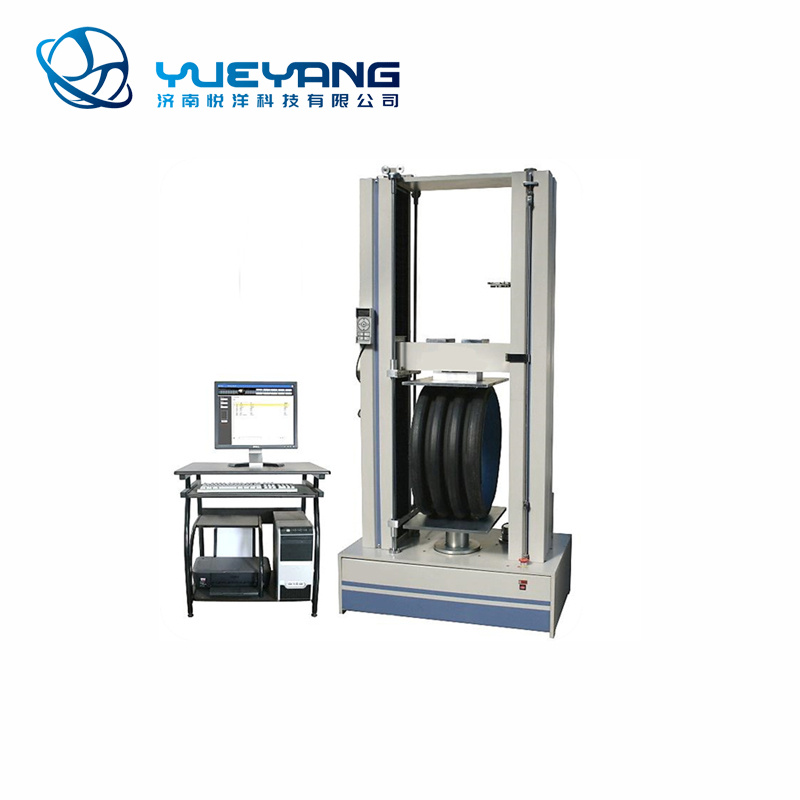

YYP-WDT-W-60B1 Electronic Universal Testing Machine

WDT series micro-control electronic universal testing machine for double screw, host, control, measurement, operation integration structure. It is suitable for tensile, compression, bending, elastic modulus, shear, peeling, tearing and other mechanical properties tests of all kinds of (thermosetting, thermoplastic) plastics, FRP, metal and other materials and products. Its software system USES the WINDOWS interface (meet the use of different countries and regions of many kinds of languages edition), according to national standards, international standards, or users with standard measurement and judgment in a variety of performance, with parameters set storage, test data acquisition, processing, analysis, display curve printing, print the test report, etc. This series testing machine is suitable for engineering plastics, modified plastics, profiles, plastic pipes and other industries of material analysis and inspection. Widely used in scientific research institutions, colleges and universities, quality inspection departments, production enterprises.

The transmission part of the series of testing machine adopts imported brand AC servo system, deceleration system, precision ball screw, high strength frame structure, according to the need can be selected with large deformation measuring device or small deformation electronic extension meter can accurately measure the deformation between the effective line of the sample. The series of testing machines into the contemporary advanced technology in one, beautiful appearance, high precision, wide speed range, low noise, easy to operate, accuracy up to 0.5 level, and provide a variety of specifications/use fixture for different users to choose. This series of products have obtained the CE certification of EU.

GB/T 1040,GB/T 1041,GB/T 8804,GB/T 9341,ISO 7500-1,GB 16491,GB/T 17200,ISO 5893,ASTM,D638,ASTM D695,ASTM D790

|

Model |

WDT-W-60B1 |

| Load Cell | 50KN |

| Test Speed | 0.01mm/min-500mm/min(Continuously viable) |

| Speed Accuracy | 0.1-500mm/min <1%; 0.01-0.05mm/min <2% |

| Displacement resolution | 0.001mm |

| Displacement Stroke | 0-1200mm |

| Distance berween two columns | 490mm |

| Test Range | 0.2%FS-100%FS |

| Sampling accuracy of force value | <±0.5% |

| Accuracy Grade | 0.5级 |

| Control Method | PC control; Color printer output |

| Power Supply | 220V 750W 10A |

| Outside Dimensions | 920mm×620mm×1850mm |

| Net Weight | 330Kg |

| Options | Large deformation measuring device, pipe inner diameter measuring device |

The test software system is developed by our company (with independent intellectual property rights), the multi-language version to meet the needs of users in different countries and regions.

Meet ISO, JIS, ASTM, DIN, GB and other test methods standards

With displacement, elongation, load, stress, strain and other control modes

Automatic storage of test conditions, test results and other data

Automatic calibration of load and elongation

The beam is slightly adjusted for easy calibration

Remote control mouse and other diversified operation control, easy to use

Has batch processing function, can be convenient and fast continuous test

The beam automatically returns to the initial position

Display dynamic curve in real time

Can choose the stress-strain, force-elongation, force-time, strength-time test curve

Automatic coordinate transformation

Superposition and comparison of test curves of the same group

Local amplification analysis of the test curve

Automatically analyze test data

Large deformation measuring device

Standard distance:mm:10/25/50 Max deformationmm:900 Accuracy(mm):0.001

Tube inner diameter measuring device