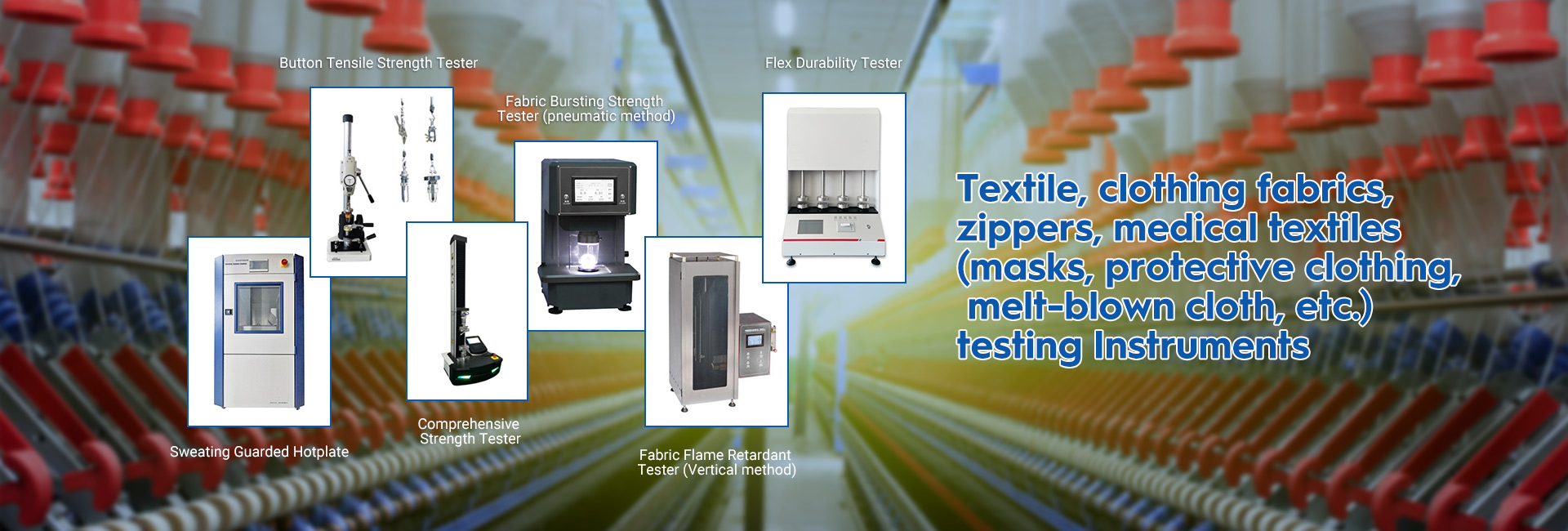

YYP134 Leak Tester

DRK134 Leak Tester is an advanced and intelligent tester designed according to related standard. It is applicable to test the seal property of flexible pack in food industry, pharmacy industry and daily chemical industry.

Micro-computer control, LCD display, PVC operation board;

Digital preset vacuum degree and vacuum maintenance time;

World famous pneumatic components;

Automatic supplementation for constant pressure;

Automatic ending;

Automatic reverse-pressure unloading.

Seal property test, leakage test, package completeness test, micro-leakage test, CO2 leak detection of bags, blister packaging, bottle, etc.

- Food industry

Flexible package: milk power in bags, cheese, coffee strip /bag, moon cake package, sachet, snake food package, tea bag, rice in bag, chips package, cake package, puffed food package, tetra pak, wet tissue bag, melon seeds bag…In total, it can test different food package with any shape, any material and any size.

Half-hard package: chilled free pork package, fruit and vegetable salad package, salver package, retort pouch package, yoghourt package, tomato sauce package, bulk chips package, jelly package…In total, it can test different half-hard package with any material and many size.

Hard package: milk power can, beverage bottle, oil drum, tin, biscuit keg, coffee bottle, zip-top can, cruet…In total, it can test different hard package with any shape, any material and any size.

2. Pharmacy industry:

Sealed container: Any sealed container with any shape, any material and any size, such as penicillin bottle, ampoule bottle, hypodermic syringe, oral liquid, aseptic bag, infusion vessel/bottle, water injection, powder-injection, BFS bottle, API bottle, BPC bottle, FFS bottle.

Blister packaging: power, troche, capsule, contact lens and so on.

Small headspace air packaging: granule packing, small power package and so on.

3. Other industries: Tyvek, aluminum foil, eyes drops.

GB/T 15171 - Test Method for Leaks in Sealed Flexible Packages

ASTM D3078 – Test Method for Leaks in Heat-Sealed Flexible Packages

| Items | Parameter |

| Accuracy | ±1% of reading force |

| Vacuum Degree | 0~ -90kPa |

| Size of Vacuum Chamber | ф270mm x 210mm(H) (Standard)Ф360mm x 585mm(H) (Optional)Ф460mm x 330mm(H) (Optional) |

| Gas Source Pressure | 0.7MPa (Users provide gas source themselves) |

| Gas Inlet | Φ6mm polyurethane pipe |

| Dimensions | 470 mm(L)×300 mm(W)×190 mm(H) |

| Power | AC 220V 50Hz |

| Net Weight | 12 Kg |

Standard:

One vacuum Chamber, one machine base, one vacuum meter, one adapter connector, two pipes, one operation manual, one guarantee card, one certificate of quality.

Note: the gas inlet of this tester isΦ6mm polyurethane pipe; users provide gas source themselves.