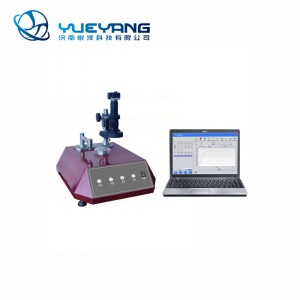

YYT-T451 Chemical Protective Clothing Jet Tester

1. Safety signs:

The contents mentioned in the following signs are mainly to prevent accidents and dangers, protect operators and instruments, and ensure the accuracy of test results. Please pay attention!

The splash or spray test was conducted on the dummy model wearing the indicating clothing and protective clothing to indicate the stain area on the clothing and to investigate the liquid tightness of the protective clothing.

1. Real time and visual display of liquid pressure in pipe

2. Automatic record of spraying and splashing time

3. High head multi-stage pump provides test solution continuously under high pressure

4. The anticorrosive pressure gauge can accurately indicate the pressure in the pipeline

5. The fully enclosed stainless steel mirror is beautiful and reliable

6. The dummy is easy to remove and wear the instruction clothing and protective clothing

7. Power supply AC220 V, 50 Hz, 500 W

The requirements of GB 24540-2009 "protective clothing for acid and alkali chemicals" test method can be used to determine the spray liquid tightness and spray liquid tightness of chemical protective clothing.

Protective clothing - Test methods for protective clothing against chemicals - Part 3: Determination of resistance to liquid jet penetration (spray test) (ISO 17491-3:2008)

ISO 17491-4-2008 Chinese Name: protective clothing. Test methods for clothing for chemical protection. Fourth part: Determination of penetration resistance to liquid spray (spray test)

1. The motor drives the dummy to rotate at 1rad / min

2. The spray angle of spray nozzle is 75 degree, and the instantaneous water spraying speed is (1.14 + 0.1) L/min at 300KPa pressure.

3. The nozzle diameter of the jet head is (4 ± 1) mm

4. The inner diameter of nozzle tube of nozzle head is (12.5 ± 1) mm

5. The distance between the pressure gauge on the jet head and the nozzle mouth is (80 ± 1) mm