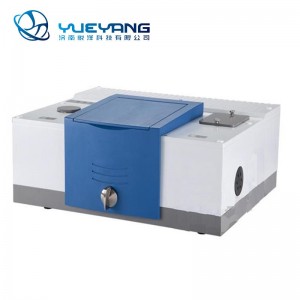

YYT026G Mask Comprehensive Strength Tester(Double Colum)

Used for testing all kinds of masks, medical protective clothing and other products.

GB 19082-2009

GB/T3923.1-1997

GB 2626-2019

GB/T 32610-2016

YY 0469-2011

YY/T 0969-2013

GB 10213-2006

GB 19083-2010

Instrument hardware:

1. Color touch-screen display operation, Chinese and English interface, menu operation mode.

2. Imported servo driver and motor (vector control), motor response time is short, no speed overrush, speed uneven phenomenon.

3. Ball screw, precision guide rail, long service life, low noise, low vibration.

4. Imported encoder for accurate control of instrument positioning and elongation.

5. Equipped with high precision sensor, "STMicroelectronics" ST series 32-bit MCU, 24-bit A/D converter.

6.Configuration manual or pneumatic fixture (clips can be replaced) optional, and can be customized root customer materials.

7. The whole machine circuit standard modular design, convenient instrument maintenance and upgrade.

Software features:

1. The software supports Windows operating system, out of the box, very convenient, without professional training.

2.Computer online software support Chinese and English operation.

3.Built-in multiple test functions, including a variety of material strength test methods. And can be customized according to customer requirements. The test procedure has been solidified by the user, the parameters are set with default values, users can modify.

4. Support pre tension sample tension clamping and free clamping.

5.Distance length digital setting, automatic positioning.

6.Conventional protection: mechanical switch protection, upper and lower limit travel, overload protection, over-voltage, over-current, overheating, under-voltage, under-current, leakage automatic protection, emergency switch manual protection.

7.Force value calibration: digital code calibration (authorization code), convenient instrument verification, control precision.

8. Software analysis function: breaking point, breaking point, stress point, yield point, initial modulus, elastic deformation, plastic deformation, etc. The statistical point function is to read the data on the measured curve. It can provide 20 groups of data, and obtain the corresponding elongation or force value according to the different force value or elongation input by the user. During the test, the selected part of the curve can be zooming in and out at will. Click on any test point to display the tensile value and elongation value, multiple curve superposition and other functions.

9. The test data and curve report can be converted into Excel, Word, etc., automatic monitoring test results, convenient to connect with customer enterprise management software.

10. Test units can be arbitrarily converted, such as newtons, pounds, kilograms of force and so on.

11. Unique (host, computer) two-way control technology, so that the test is convenient and fast, the test results are rich and varied (data reports, curves, graphs, reports).

1.Range and indexing value: 2500N (250kg), 0.1N (0.01g)

2.The resolution of force value 1/60000

3.Force sensor accuracy: ≤±0.05%F·S

4. The machine load accuracy: full range of 2% ~ 100% any point accuracy ≤±0.1%, grade: 1 level

5.Speed range :(0.1 ~ 1000) mm/min (within the range of free setting)

6. Effective stroke: 800mm

7. Displacement resolution: 0.01mm

8.The minimum clamping distance: 10mm

9. Clamping distance positioning mode: digital setting, automatic positioning

10.Unit conversion: N, CN, IB, IN

11. Data storage (host part) :≥2000 groups

12. Power supply: 220V,50HZ,1000W

13. External size: 800mm×600mm×2000mm (L×W×H)

14. Weight: about 220kg