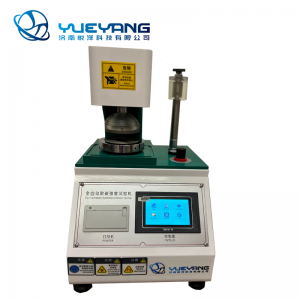

YYT124C–Respiratory Mechanical Strength Vibration Tester

The filter element vibration tester of respirator is designed and manufactured according to relevant standards. It is mainly used for vibration mechanical strength pretreatment of replaceable filter element.

Working power supply: 220 V, 50 Hz, 50 W

Vibration amplitude: 20 mm

Vibration frequency: 100 ± 5 times / min

Vibration time: 0-99min, settable, standard time 20min

Test sample: up to 40 words

Package size (L * w * h mm): 700 * 700 * 1150

26en149 et al

One electric control console and one power line.

See packing list for others

safety signs safety warnings

packaging

Do not put in layers, handle with care, waterproof, upward

transportation

In the state of transportation or storage packaging, the equipment must be able to be stored for less than 15 weeks under the following environmental conditions.

Ambient temperature range: - 20 ~ + 60 ℃.

1. Safety criteria

1.1 before installing, repairing and maintaining the equipment, the installation technicians and operators must read the operation manual carefully.

1.2 before using the equipment, operators must carefully read gb2626 and be familiar with the relevant provisions of the standard.

1.3 the equipment must be installed, maintained and used by specially responsible personnel according to the operation instructions. If the equipment is damaged due to incorrect operation, it is no longer within the scope of warranty.

2. Installation conditions

Ambient temperature: (21 ± 5) ℃ (if the ambient temperature is too high, it will accelerate the aging of electronic components of the equipment, reduce the service life of the machine, and affect the experimental effect.)

Environmental humidity: (50 ± 30)% (if the humidity is too high, the leakage will easily burn the machine and cause personal injury)

3. Installation

3.1 mechanical installation

Remove the outer packing box, carefully read the instruction manual and check whether the machine accessories are complete and in good condition according to the contents of the packing list.

3.2 electrical installation

Install power box or circuit breaker near the equipment.

In order to ensure the safety of personnel and equipment, the power supply must have reliable grounding wire.

Note: the installation and connection of power supply must be carried out by professional electrical engineer.