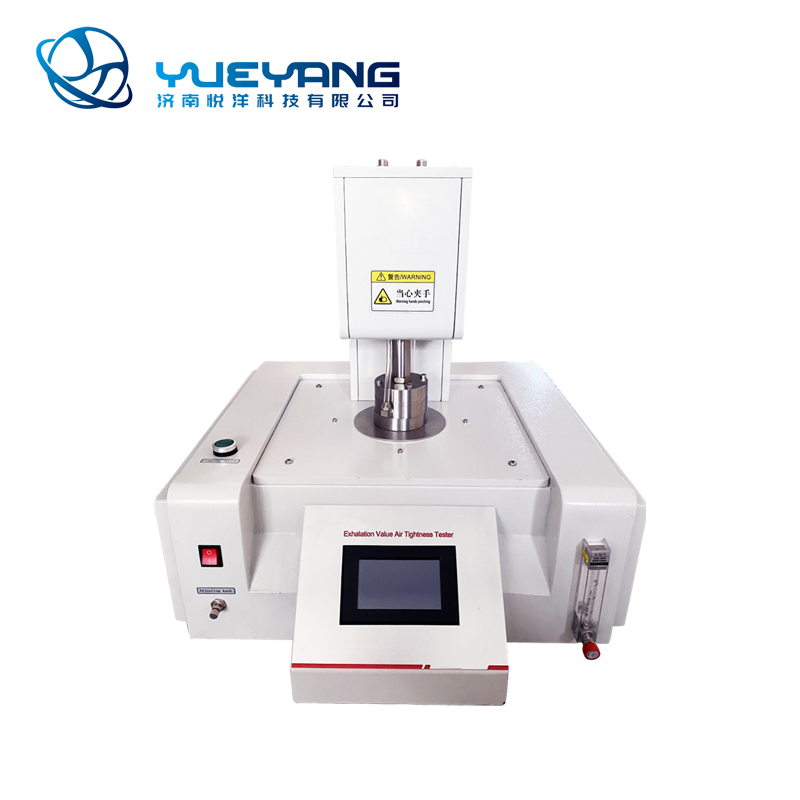

YYT268 Exhalation Value Air Tightness Tester

1.1 Overview

It is used to detect the air tightness of the breathing valve of the self-priming filter type anti particle respirator. It is suitable for labor safety protection inspection

Center, occupational safety inspection center, disease prevention and control center, respirator manufacturers, etc.

The instrument has the characteristics of compact structure, complete functions and convenient operation. The instrument adopts single chip microcomputer

Microprocessor control, color touch screen display.

1.2. Main features

1.2.1 high definition color touch screen, easy to operate.

1.2.2 the micro pressure sensor has high sensitivity and is used to collect test data pressure.

1.2.3 high precision gas flowmeter can accurately measure the leakage gas flow of expiratory valve.

Convenient and quick pressure regulating device.

1.3 Main specifications and technical indexes

1.3.1 the buffer capacity shall not be less than 5 liters

1.3.2 range: - 1000pa-0pa, accuracy 1%, resolution 1pA

1.3.3 the pumping speed of vacuum pump is about 2L / min

1.3.4 flow meter range: 0-100ml / min.

1.3.5 power supply: AC220 V, 50 Hz, 150 W

1.3.6 overall dimension: 610 × 600 × 620mm

1.3.7 weight: 30kg

1.4 Working environment and conditions

1.4.1 room temperature control range: 10 ℃~ 35 ℃

1.4.2 relative humidity ≤ 80%

1.4.3 there is no vibration, corrosive medium and strong electromagnetic interference in the surrounding environment.

1.4.4 power supply: AC220 V ± 10% 50 Hz

1.4.5 grounding requirements: the grounding resistance is less than 5 Ω.

2.1. Main components

The external structure of the instrument is composed of the instrument shell, test fixture and operation panel; the internal structure of the instrument is composed of pressure control module, CPU data processor, pressure reading device, etc.

2.2 working principle of the instrument

Take appropriate methods (such as using sealant), seal the exhalation valve sample on the exhalation valve test fixture in an airtight manner, open the vacuum pump, adjust the pressure regulating valve, make the exhalation valve bear the pressure of - 249pa, and detect the leakage flow of the exhalation valve.