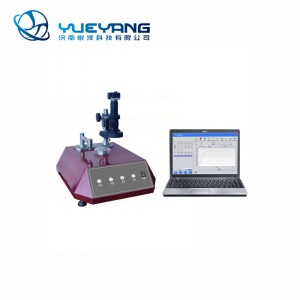

YYT503 Schildknecht Flexing Tester

1. Purpose:

The machine is suitable for repeated flexure resistance of coated fabrics, providing reference for improving fabrics.

2. Principle:

Place a rectangular coated fabric strip around two opposite cylinders so that the specimen is cylindrical. One of the cylinders reciprocates along its axis, causing alternating compression and relaxation of the coated fabric cylinder, causing folding on the specimen. This folding of the coated fabric cylinder lasts until a predetermined number of cycles or the specimen is obviously damaged.

3. Standards:

The machine is made according to BS 3424 P9, ISO 7854 and GB / T 12586 B method.

1. Instrument structure:

Instrument structure:

Function Description:

Fixture: install the sample

Control panel: including control instrument and control switch button

Power line: provide power for the instrument

Leveling foot: adjust the instrument to the horizontal position

Sample installation tools: easy to install samples

2. Description of control panel:

Composition of control panel:

Control panel Description:

Counter: counter, which can preset the test times and display the current running times

Start: Start button, press the friction table to start swinging when it stops

Stop: stop button, press the friction table to stop swinging when testing

Power: power switch, on / off power supply

| Project |

Specifications |

| Fixture | 10 groups |

| Speed | 8.3Hz±0.4Hz(498±24r/min) |

| Cylinder | The outer diameter is 25.4mm ± 0.1mm |

| Test track | Arc r460mm |

| Test trip | 11.7mm±0.35mm |

| Clamp | Width: 10 mm ± 1 mm |

| Inside distance of clamp | 36mm±1mm |

| Sample size | 50mmx105mm |

| Number of samples | 6, 3 in longitude and 3 in latitude |

| Volume (WxDxH) | 43x55x37cm |

| Weight (approximately) | ≈50Kg |

| Power Supply | 1∮ AC 220V 50Hz 3A |